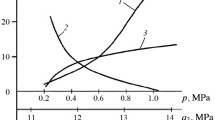

An analysis of the influence of gasket material, gasket size, and pressure of the working medium on the selection of the initial width of the gasket is presented for the first time. Based on this analysis, a previously derived equation was used to determine the width of a compressed gasket placed between flanges in the working state. To perform the analysis, we used the investigation results that showed that an annular gasket expands only along its outer boundary when pressed axially and there are no limitations to its radial deformation. The materials for these gaskets are rubber, fluoroplastic-4 (polytetrafluoroethylene, tradename Teflon), and AD-grade aluminum; the diameters of the sealed holes are 100, 200, and 300 mm, and the pressure of the medium being sealed is 5–10 MPa. These data helped assess the influence of the mechanical properties of the gasket material, the gasket size, and the operation conditions (pressure of the medium being sealed) on the selection of the appropriate gasket width. Two versions of gasket positioning between the flanges are examined: in one the sealing flange surfaces are smooth, in the other the joints are of the projection–depression type. The investigations demonstrated that in the test case the method of positioning of the gasket between flanges does not materially influence the selection of the required gasket width. While taking the properties of the gasket material (rubber and Teflon) into account, we assumed that the material is incompressible (Poison’s ratio close to 0.5). In the case of aluminum, we took the influence of compressibility of the material into consideration. The obtained analysis results are somewhat approximate because the force of friction between the surfaces of the flanges and the gasket that is deformed radially was not taken into account, and the force of preliminary compression of the gasket was taken as the average value between the yield limit of the gasket material and the limit load on the gasket, at which the elasticity of the gasket material is retained under the operating conditions. The data presented on the selection of the initial appropriate gasket width will doubtlessly become the essential material for designing flange joints.

Similar content being viewed by others

References

G. V. Bozhko, V. D. Prodan, T. V. Shadrina, et al., “Selection of gasket width for flanged joints,” Khim. Neftegaz. Mashinostr., No. 5, 8–9 (2003).

I. A. Birger and G. B. Iosilevich, Threaded and Flanged Joints [in Russian], Mashinostroenie, Moscow (1990).

V. D. Prodan, G. V. Bozhko, and A. V. Vasil’ev, “Radial deformation of a ring gasket under axial compression,” Khim. Neftegaz. Mashinostr., No. 11, 34–36 (2011).

A. I. Goshko, V. D. Prodan, and A. S. Astsaturov, Mounting and Technique of Sealing a Flanged Assembly: A Technical Handbook [in Russian], Instrument, Moscow (2004).

G. V. Bozhko, “Influence of type of loading on deformation characteristics of fluoroplastic-4 gaskets,” Khim. Neftegaz. Mashinostr., No. 12, 32–34 (2007).

S. P. Timoshenko, Resistance of Materials [in Russian], Nauka, Moscow (1965), Vol. 1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 4, pp. 30–32, April, 2013.

Rights and permissions

About this article

Cite this article

Prodan, V.D., Vasil’ev, A.V. & Dubinina, A.S. Influence of pressure of sealed medium, inner diameter, and materials on selection of initial gasket width. Chem Petrol Eng 49, 251–255 (2013). https://doi.org/10.1007/s10556-013-9734-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-013-9734-4