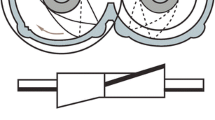

It is proposed to classify mixer, dispersal, and combined (mixer-dispersal) units of screw extruders for processing thermoplastic materials. Examples are provided of structural formulation for these units, and their advantages and disadvantages are demonstrated.

Similar content being viewed by others

References

G. Shenkel, Screw Presses for Plastics. Operating Principle, Construction, and Exploitation [in Russian], Goskhimizdat, Leningrad (1962).

V. S. Kim and V. V. Skachkov, Dispersion and Mixing in Polymer Production and Processing [in Russian], Khimiya, Moscow (1988).

C. Rauwendaal, Understanding Extrusion, Carl Verlag, Munich (1998).

D. B. Todd, “Improving incorporation of fillers in plastics. A special report,” Adv. Polym. Technol., 19 No. 1, 54–64 (2000).

C. Rauwendaal, Polymer Extrusion [Russian translation], Professiya, St. Petersburg (2006).

V. P. Britov, V. V. Bogdanov, O. O. Nikolaev, et al., “Activation mixing during preparation and modification of polymer composite materials,” Zh. Prikl. Khim., 77, No. 1, 122–127 (2004).

I. O. Mikulionok, Equipment and Processes for Treating Thermoplastic Materials with Use of Secondary Raw Material [in Ukrainian], Politekhnika, Kiev (2009).

I. O. Mikulionok and L. B. Rafchenko, “Screw extrusion of thermoplastics. I. General model of screw extrusion,” Russ. J. Appl. Chem., 85, No.3, 489509 (2012).

R. V. Torner and M. S. Akutin, Plant Equipment for Plastic Processing [in Russian], Khimiya, Moscow (1986).

Ukraine Patent 54803 U, IPC B29C 47/38, “Screw extruder,” Byull., No. 22 (2010).

USSR Inventor’s Cert. 1781049, IPC B29C 7/30, “Static mixer for polymer materials,” Byull., No. 46 (1992).

Ukraine application u201114137, IPC B29C 47/32, “Static Mixer,” subm. 11.30.2011.

Ukraine patent 53891 U, IPC B29C 47/60, “Screw extruder section,” Byull., No. 20 (2010).

Ukraine patent 47082 U, IPC B29/C 47/60, “Screw extruder,” Byull., No. 1 (2010).

Ukraine application u201201739, IPC B29/C 47/60, “Screw extruder mixer section,” subm. 02.16. 2012.

German application No. DE102006009867 A1, IPC B29/C 47/64, “Device for extruder,” subm. 03.03.2006.

German application No. DE102006023835 A1, IPC B29/C 47/66, “Extruder with controlled feed intensity,” subm. 03.03.2006.

A. G. Govsha, V. V. Bastyrgin, and A. V. Ostroukhov, State, Application Prospects, and Development of Single-Screw Rubber-Processing Machines: Inform. Review, Ser. KhM-2: Equipment for Plastic and Rubber Processing [in Russian], TsINTIkhimneftmash, Moscow (1966).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 2, pp. 26–30, February, 2013.

Rights and permissions

About this article

Cite this article

Mikulionok, I.O. Screw extruder mixing and dispersing units. Chem Petrol Eng 49, 103–109 (2013). https://doi.org/10.1007/s10556-013-9711-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-013-9711-y