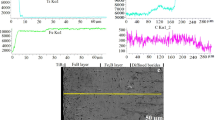

Results are provided for corrosion tests of steel specimens with coatings of different compositions, prepared by surfacing under the action of a laser beam. Data are provided for weight loss of specimens coated with highly alloyed corrosion-resistant and tool steels, tin bronze, and alloys based on nickel and cobalt. The pH of working solutions is 3.1–9.0. the nature of corrosion damage and specimen transverse section structure are described. Research shows that use of protective coatings based on steel and on nonferrous metals may considerably reduce breakdown of objects manufactured from structural steels. The most marked reduction in weight loss due to corrosion develops for a coating based on cobalt (up to 82 %). Alloys based on nickel and highly alloyed steels SS316L and SS410L showed an increase in corrosion resistance from 38 to 43 %.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 6, pp. 36–38, June, 2012.

Rights and permissions

About this article

Cite this article

Mazurkevich, A.N., Shiganov, I.N., Tretyakov, R.S. et al. Study of corrosion resistance of coatings of different composition prepared by laser surfacing. Chem Petrol Eng 48, 380–383 (2012). https://doi.org/10.1007/s10556-012-9627-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-012-9627-y