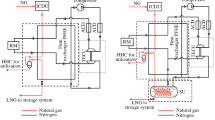

This paper is devoted primarily to thermodynamic analysis of cycles implemented in three low-capacity pilot plants for liquefaction of natural gas (in Moscow, St. Petersburg, and Yekaterinburg). In our opinion, results of the research conducted will undoubtedly be defined more precisely in possible replication of small-capacity plants, or the creation of new ones.

Similar content being viewed by others

Notes

Actually, the existing plant is equipped with four compressors, each with an output of 900 nm3/h and a 125-kW electric motor. Overall output is 925 kg of liquid CH4/h with respect to liquid methane, and G CH4 = 4·900 nm3/h·0.667 kg/nm3 = 2401 kg/h with respect to the compressed gas. A vapor-compression spiral refrigerating machine manufactured by the Grasso Co. with a refrigerating capacity (cold capacity) of 110 kW at 238 K is used for prechilling.

The actual existing plant is equipped with two compressors each with an output of 1740 nm3/h with a 295-kW electric motor. The total output is: 961 kg of liquid CH4/h with respect to liquid methane, and G CH4 = 2·1740 nm3/h·0.667 kg/nm3 = 2324 kg/h with respect to the compressed gas. A K-127 vapor-compression piston refrigerating machine with a refrigerating capacity (cold-generating capacity) of 175 kW at 238 K is used for preliminary chilling.

References

A. M. Arkharov and V. V. Sychev, “Fundamentals of statistical-entropy analysis of actual energy losses in low- and high-temperature machines and plants,” Kholod. Tekhnika, No. 12 (2005).

A. M. Arkharov and V. V. Sychev, “And yet again entropy and the problem of determining actual (effective) energy losses due to irreversibility,” Kholod. Tekhnika, No. 4 (2007).

A. M. Arkharov, V. V. Sychev, and I. A. Arkharov, “Refrigeration and Cryogenic Engineering, Conditioning and Life-Sustaining Systems,” Vestn. Mos. Gos. Tekhn. Univ. im. N. E. Baumana (2008).

A. M. Arkharov, “On united thermodynamic space, heat, cold, exergy, and entropy as regards basic concepts of engineering cryology,” Kholod. Tekhn., Special issue, No. 6 (2009).

V. Yu. Semenov et al., Russian Federation Patent No. 2180081, “Method for liquefaction of methane preferentially for transportation-related gas-filling stations.”

V. Yu. Semenov et al., Russian Federation Patent No. 2180082, “Methane-liquefaction plant preferentially for trans-portation-related gas-filling stations.”

S. P. Gorbachev, “Effectiveness of LNG production procedures at TGFCS,” Avto Gazozapr. Kompleks + Altern. Toplivo (2005).

Cool Pack Program, ver. 1.46.

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 7, pp. 24–35, July, 2010.

Rights and permissions

About this article

Cite this article

Arkharov, A.M., Arkharov, I.A., Shevich, Y.A. et al. Analysis of existing small-capacity plants for natural-gas liquefaction. Chem Petrol Eng 46, 397–416 (2010). https://doi.org/10.1007/s10556-010-9351-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-010-9351-4