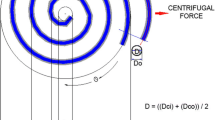

Two-dimensional flow is considered for a bladed ring with relative extent of the channel between blades less than 6. Hydrodynamic equations are used with an empirical formula for the hydraulic losses by friction in order to derive a general expression for the radial distributions of the axial and circumferential components of the flow velocity beyond the device without reverse flows at the input and counterflows at the output. The calculations are shown to agree satisfactorily with the experimental data.

Similar content being viewed by others

References

B. V. Ovsyannikov and B. I. Borovskii, Theory and Design of LRE Supply Facilities [in Russian], Mashinostroenie, Moscow (1979).

A. A. Lomakin, Centrifugal and Axial Pumps [in Russian], Mashinostroenie, Moscow and Leningrad (1966).

B. I. Borovskii, N. S. Ershov, B. V. Ovsyannikov, et al., High-Speed Bladed Pumps [in Russian], Mashinostroenie, Moscow (1975).

I. V. Shcherbatenko and V. I. Surikov, “Flow-speed distribution after a spiral-blade device in a centrifugal pump,” Khim. Neftegaz. Mashinostr., No. 4, 21–25 (2005).

Lakshminarayana, “Hydrodynamics of input devices for pumps (survey),” Theor. Princ. Eng. Calcul., No. 4, 66–87 (1982).

I. V. Shcherbatenko, “Pressure characteristic calculation for booster pumps,” Teploenergetika, No. 2, 64–70 (1996).

Davis, Coons, and Shear, “Flow analysis in prepumping units operating with cavitation and without it,” Vopr. Raket. Tekhn., No. 11, 25–39 (1972).

K. Kamije and A. Sujuki, “An experimental study of an inductor containing spiral planes for a turbine pump rocket” [Russian translation from the Japanese], Keku Utyu Gijyutsu Kenkyuje Hohoku, No. 354, 1–28 (1982).

Sanderhock, Soltis, and Anderson, “Cavitational and cavitation-free characteristics of a constant-pitch spiral device and spiral rise angle 80.6° at three speeds,” TsIAM Technical Translation into Russian, D-1439 (1962).

Y. Takamtsu and A. Furukawa, “A study of the flow structure beyond a spiral-aperture disk of constant pitch,” Trans. JSME, 44, No. 379, 950–959 (1978).

A. S. Shapiro, Structure of the Actual Flows in Centrifugal and Axial Pumps [in Russian], MGIU, Moscow (2004).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 2, pp. 24–27, February, 2009.

Rights and permissions

About this article

Cite this article

Shcherbatenko, I.V., Surikov, V.I. A study of the flow in spiral-channel disks. Chem Petrol Eng 45, 85–91 (2009). https://doi.org/10.1007/s10556-009-9149-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-009-9149-4