Abstract

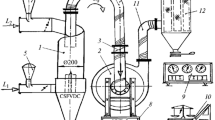

The operating principle of dust collectors with swirling counterflows (SC) is examined. An efficiency of 80–85% is achieved during tests of an SC vessel under industrial conditions. The velocity fields of the gas flow in different sections are analyzed over the height of the SC vessel. The influence exerted by the taper of the effective zone of the SC vessel on the dust-entrapment efficiency is investigated. Results are presented for comparative hydrodynamic tests of cylindrical and conical SC dust collectors.

Similar content being viewed by others

References

B. S. Sazhin and P. I. Gudim, “Dust collectors with swirling counterflows,” Khim. Prom., No. 8, 498–509 (1985).

E. V. Frolov, “Hydrodynamics and effectiveness of dust collectors with swirling counterflows,” Author’s Abstract of Dissertation for Candidate of Technical Sciences, Institut Khimicheskogo Mashinostroeniya, Moscow (1983).

T. Yu. Vekua, “Hydrodynamics of multifunctional vessels with swirling counterflows,” Author’s abstract of Dissertation for Candidate of Technical Sciences, Moskovskii Tekhnologicheskii Institut, Moscow (1979).

E. G. Ovcharenko and I. A. Petrov, “A complex approach to reduction of dust emissions in the production of expanded pearlite,” Stroit. Mater., No. 4, 10–11 (1988).

B. S. Sazhin, T. Yu. Vekua, and I. A. Popov, “Velocity fields in a vessel with swirling counterflows,” Materials Presented at the Scientific Conference [in Russian], Moskovskii Tekhnologicheskii Institut, Moscow (1979), pp. 28–33.

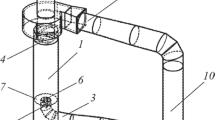

I. A. Petrov, É. F. Shurgal’skii, E. V. Frolov, et al., USSR Author’s Certificate No. 1286297, “ Vessel for separation of media in swirling counterflows,” Byull. Izobr., No. 4 (1987).

I. A. Petrov, A. G. Zen’kovskii, and E. G. Ovcharenko, “Conical SC dust collectors,” New Production Processes in Industrial Thermal Insulation, Collection of Proceedings of the All-Union Research and Planning Institute for Heat Engineering Structures [in Russian], Moscow (1987), pp. 86–90.

P. A. Kouzov and P. Ya. Skryabina, Methods of Determining Physicochemical Properties of Industrial Dusts [in Russian], Khimiya, Leningrad (1983).

M. Samet and S. Einav, Rev. Sci. Instruments, 55, No. 4, 582–588 (1984).

Author information

Authors and Affiliations

Additional information

__________

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 6, pp. 9–11, June, 2007.

Rights and permissions

About this article

Cite this article

Petrov, I.A., Shurgal’skii, É.F. & Chepura, I.V. Operating efficiency and hydrodynamics of conical dust collectors with swirling counterflows. Chem Petrol Eng 43, 307–311 (2007). https://doi.org/10.1007/s10556-007-0054-4

Issue Date:

DOI: https://doi.org/10.1007/s10556-007-0054-4