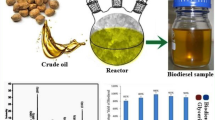

The authors investigate biodiesel fuel and the possibility to utilize biodiesel as an environmentally-friendly alternative fuel for diesel applications in Iran. The common source of oil resources for biodiesel production is the vegetable seeds oil. In this study, the seeds of the castor-oil plant are selected to investigate the process of oil extraction and biodiesel production in a single-phase process. The production process is characterized by the factors of time, choice of catalyst, and the ratio of oil extracted by alcohol (ethanol). The calcined eggshell used as a nano-catalyst in the process of extraction has been previously powdered in a ball mill to the average particle diameter of 500 Å and annealed for two hours under the temperature of 1200°C immediately prior to the extraction reaction. The experimental results show that the optimal conditions for the single-phase process are as follows: the reaction time is 5 h, the catalyst amount is 3 g, and the ethanol/oil molar ratio is 4,5. Due to the presence of the eggshell nano-catalyst, the time of extraction is significantly reduced. Considering the economic and the cost issues, it was shown that the optimal parameters can provide the highest yield of biodiesel of sufficient quality. The results indicate that the vegetable seeds oil can be successfully used for biodiesel production, thus contributing to the fuel supply, as well as reducing air pollution.

Similar content being viewed by others

References

S. X. Tana, S. Lim, H. C. Ong, and Y. L. Pang, “State of the art review on the development of ultrasound-assisted catalytic transesterification process for biodiesel production,” Fuel, 235, 886-907(2019).

A. Arumugam, V. Ponnusami, “Biodiesel production from Calophyllum inophyllum oil a potential non-edible feedstock: An overview,” Renew. Energy, 131, 459-471 (2019).

I. Lawan, Z. N. Garba, W. Zhou, M. Zhang, and Z. Yuan, “Synergies between the microwave reactor and CaO/zeolite catalyst in waste lard biodiesel production,” Renew. Energy, 145, 2550-2560 (2020).

K. N. Krishnamurthy, S. N. Sridhara, and C. S. Ananda Kumar, “Optimization and kinetic study of biodiesel production from Hydnocarpus wightiana oil and dairy waste scum using snail shell CaO nanocatalyst,” Renew. Energy, 146, 280-296 (2020).

J. Janaun and N. Ellis, “Perspectives on biodiesel as a sustainable fuel,” Renew. Sustain. Energy Rev., 14, 1312-1320 (2010).

A. Murugesan, C. Umarani, T. R. Chinnusamy, M. Krishnan, R. Subramanian, and N. Neduzchezhain, “Production and analysis of biodiesel from non-edible oils - a review,” Renew. Sustain. Energy Rev., 13, 825-834 (2009).

A. Patel, B. Patel, B. Patel, and N. Kulshreshtha, “Thermodynamic properties of lubricating oil,” Int. J. Eng. Trends Technol., 67(4), 42-43 (2019).

M. S. Graboski and R. L. Mccormick, “Combustion of fat and vegetable oil derived fuels in diesel engines,” Progr. Energy Combust. Sci., 24, 125-164 (1998).

C. S. Osorio-González, N. Gómez-Falcon, F. Sandoval-Salas, R. Saini, S. K. Brar, and A. A. Ramírez, “Production of biodiesel from castor oil: a review,” Energies, 13(10), 2467 (2020).

D. S. Ogunniyi, “Castor oil: a vital industrial raw material,” Bioresour. Technol., 97, 1086-1091 (2006).

B. Hurtado, A. Posadillo, D. Luna, and F. M. Bautista, “Synthesis, performance, and emission quality assessment of ecodiesel from castor oil in diesel/biofuel/alcohol triple blends in a diesel engine,” Catal., 9(01), 40 (2019).

M. Balat and H. Balat, “Progress in biodiesel processing,” Appl. Energy, 87(6), 1815-1835 (2010).

M. Balajii and S. Niju, “Biochar-derived heterogeneous catalysts for biodiesel production,” Environ. Chem. Lett., 17, 1447-1469 (2019).

P. D. Rocha, L. S. Oliveira, and A. S. Franca, “Sulfonated activated carbon from corn cobs as heterogeneous catalysts for biodiesel production using microwave-assisted transesterification,” Renew. Energy. 143, 1710-1716 (2019).

S. V. Ranganathan, S. L. Narasimham, and K. Muthukumar, “An overview of enzymatic production of biodiesel,” Bioresour. Technol., 99, 3975-3981(2008).

J. M. Dias, M. C. M. Alvim-Ferraz, and M. F. Almeida, “Comparison of the performance of different homogeneous alkali catalysts during transesterification of waste and virgin oils and evaluation of biodiesel quality,” Fuel, 87, 3572-3578 (2008).

G. Guan, K. Kusakabe, N. Sakurai, and K. Moriyama, “Transesterification of vegetable oil to biodiesel fuel using acid catalysts in the presence of dimethyl ether,” Fuel, 88, 81-86 (2009).

M. E. Borges and L. Daz, “Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: a review,” Renew. Sustain. Energy Rev., 16, 2839-2849 (2012).

Z. Helwani, M. R. Othman, N. Aziz, J. Kim, and W. J. N. Fernando, “Solid heterogeneous catalysts for transesterification of triglycerides with methanol: a review,” Appl. Catal. A: Gen., 363(1-2), 1-10(2009).

H. R. Mahmoud, “Bismuth silicate (Bi4Si3O12 and Bi2SiO5) prepared by ultrasonic-assisted hydrothermal method as novel catalysts for biodiesel production via oleic acid esterification with methanol,” Fuel, 256, 115979 (2019).

T. H. Đặng, X. H. Nguyễn, C. L. Chou, and B. H. Chen, “Preparation of cancrinite-type zeolite from diatomaceous earth as transesterification catalysts for biodiesel production,” Renew. Energy, 174, 347-358 (2021).

A. Marwaha, A. Dhir, S. K. Mahla, and S. K. Mohapatra, “An overview of solid base heterogeneous catalysts for biodiesel production,” Catal. Rev., 60(4), 594-628(2018).

A. P. Vyas, J. L. Verma, and N. S. Manyam, “A review on FAME production processes,” Fuel, 89(01), 1-9 (2010).

G. Kafuku and M. Mbarawa, “Biodiesel production from Croton megalocarpus oil and its process optimization,” Fuel, 89(09), 2556-2560 (2010).

W. Xie and H. Wang, “Grafting copolymerization of dual acidic ionic liquid on core-shell structured magnetic silica: a magnetically recyclable Brönsted acid catalyst for biodiesel production by a one-pot transformation of low-quality oils,” Fuel, 283, 118893 (2021).

J. Clohessy and W. Kwapinski, “Carbon-based catalysts for biodiesel production - a review,” Appl. Sci., 10(3), 918 (2020).

T. V. de Medeiros, A. Macina, and R. Naccache, “Graphitic carbon nitrides: efficient heterogeneous catalysts for biodiesel production,” Nano Energy, 78, 105306 (2020).

J. Vakros, “Biochars and their use as transesterification catalysts for biodiesel production: a short review,” Catal., 8(11), 562 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 1, pp. 82–88, January – February, 2022.

Rights and permissions

About this article

Cite this article

Dalvand, P., Mahdavian, L. Biodiesel Production in the Presence of Eggshell Nano-Catalyst. Chem Technol Fuels Oils 58, 55–62 (2022). https://doi.org/10.1007/s10553-022-01351-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-022-01351-1