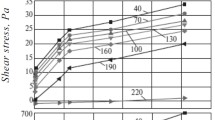

Free-radical polymerization in solution was used to synthesize a terpolymer consisting of acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, and styrene sulfonate. Drilling fluids based on the terpolymer were prepared for use in high-temperature and high-pressure wells. The rheological properties of the drilling fluids based on the terpolymer were analyzed by the regression method. We found that the rheological properties of the drilling fluids at high temperature and high pressure can be described by the Casson model. A mathematical model is proposed for predicting the downhole viscosity of drilling fluids containing the terpolymer at high temperature and high pressure.

Similar content being viewed by others

References

G. R. Gray, H. C. H. Darley, and W. F. Rogers, Composition and Properties of Oil Well Drilling Fluids, Gulf Publishing Company, Houston, Texas (1980).

G. V. Chilingarian and P. Vorabutr, Drilling and Drilling Fluids, Elsevier Science Publishing Company, New York (1983).

Tongtai Xu, Leliang Cheng , and Pingya Luo, Deep Well Slurry. Petroleum Industry Press, Beijing (1994).

Md. Amanullah and Yu Long, “Environment friendly fluid loss additives to protect the marine environment from the detrimental effect of mud additives,” Journal of Petroleum Science and Engineering, 145, 156–164 (2005)

Jienian Yan, Drilling Fluids Technology, University of Petroleum Press, Dongying (2001).

J. V. Fisk and D. E. Jamison, “Physical properties of drilling fluids at high temperatures and pressures,” SPE Drilling Engineering, 4, 341-346 (1989).

M. V. Voinova, M. Rodahl, M. Jonson, and B. Kasemo, Physica Scripta, 59, 391 (1999).

L. J. Lee and A. D. Patel, US Pat. 5,635,458 (1997).

J. C. Reis, Environmental Control in Petroleum Engineering, Gulf Publishing Company, Houston, Texas (1996).

B. B. Patel, US Pat. 6,124,245 (2000).

K. A. Bair, F. Chen, M. Melbouci, T. S. Young, and D. K. Loo, US Pat. 6,590,050 (2003).

Y. M. Wu, B. Q. Zhang, T. Wu, and C. G. Zhang, Colloid & Polymer Science, 5, 56-64 (2001).

S. Rossi, P. F. Luckham, S. Zhu, et al., “High-pressure/high-temperature rheology of Na+-montmorillonite clay suspensions,” in: SPE International Symposium on Oilfield Chemistry, Lafayette, Louisiana, 23-24 February 1999; SPE 50725.

Yuan-Zhi Qu et al., “Preparation of poly(styrene-block-acrylamide)/organic montmorillonite nanocomposites via reversible addition–fragmentation chain transfer,” Journal of Applied Polymer Science, 110, 387–391 (2008).

Johann Plank et al., “Impact of the steric position of phosphonate groups in poly(N,N-dimethylacrylamideco-2-acrylamido-2-methylpropanesulfonate-co-2-x-phosphonate) on its adsorbed conformation on cement: Comparison of vinylphosphonic acid and 2-acrylamido-2-methylpropanephosphonate modified terpolymers,” Journal of Applied Polymer Science, 112, 311–321 (2010).

P. C. Berg, E. S. Pederson, A. Lauritson, et al., “Drilling, completion, and open-hole formation evaluation of high angle wells in high density cesium formate brine: The Kvitebjorn experience,” in: SPE/IACD Drilling Conference, Oklahoma USA, 31 March-3 April 2007; SPE 105733.

Fuhua Wang, Euihe Wang, Jianghua Liu et al., “Rheology of high-density water-based drilling fluid at high temperature and high pressure,” Acta Petrolei Sinica, 31, No. 2, 306–310 (2010).

J. D. Sherwood and G. H. Meeten, “The filtration properties of compressible mud filtercakes,” Journal of Petroleum Science and Engineering, 149, 256–268 (1997).

Zhaoguang Chang, Qinghe Wang, Daicai Song et al., in: Method for Random Data Treatment, University of Petroleum Press, Dongying, China (1997); pp. 162–173.

Jienian Yan and Xionghu Zhao, “Rheological properties of oil-based drilling fluids at high temperature and high pressure,” Acta Petrolei Sinica, 24, No. 3, 104–109 (2003).

Shengying Zhao, Jienian Yan, Tongwei Ding et al., “Study on rheology properties of high-temperature and high-density water based drilling fluid,” Natural Gas Industry, 27, No. 5, 78–80 (2007).

Author information

Authors and Affiliations

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 6, pp. 22 – 27, November – December, 2012.

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 6, pp. 22 – 27, November – December, 2012.

Rights and permissions

About this article

Cite this article

Bu, H., Sun, J., Wang, C. et al. Rheological properties of polymer-gel drilling fluids at high temperature and pressure. Chem Technol Fuels Oils 48, 449–458 (2013). https://doi.org/10.1007/s10553-013-0394-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-013-0394-z