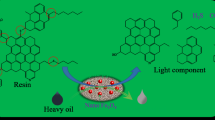

The objective of this study is to evaluate the use of emulsified heavy oils to conduct the FCC reaction. The emulsified heavy oil was prepared by homogenizing. Properties of emulsified heavy oil, including interfacial tension, dynamic viscosity, droplet distribution, and stability, were determined. Emulsified heavy oils were made using two types of pulping black liquor, namely untreated and partially recycled alkali black liquor. Stabilized emulsified heavy oil was used in the FCC reaction to investigate the product distribution, and pure heavy oil was used as the control. If the black liquor infiltration capacity is 5 wt. %, the catalytic cracking conversion and selectivity of the emulsified heavy oil and pure heavy oil were appraised at a temperature of 450°C using a fluid fixed bed.Compared with the pure heavy oil, the emulsified heavy oil had higher conversion and better selectivity towards the liquid products, and the liquid products yield of l-E-5 emulsion increases from 66.73 wt. % to 71.30 wt. %. Furthermore, the selectivity towards coke of emulsified heavy oil conversion is lower than that of the pure heavy oil, and the coke yield of l-E-5 emulsion decreases from 10.74 wt. % to 6.26 wt. %. The No.l black liquor is more suitable as a catalytic cracking black liquor fuel oil emulsifier than that of No.2 black liquor. Additionally, the negative effect of the emulsified heavy oil on the catalysis is limited, and the useful life of the catalysis was extended.

Similar content being viewed by others

References

1. Antonsson, S., Henriksson, G., Johansson, M., Lindstrom, M.E.. LowMw-lignin fractions together with vegetable oils as available oligomers for novel paper-coating applications as hydrophobic barrier. Ind.Crops Prod. 2008; 27(1):98–103.

2. Axelsson, E., Olsson, MR. and Berntsson, T.. Increased capacity in kraft pulp mills: lignin separation and reduced, steam demand compared with recovery boiler upgrade. Nordic Pulp Paper Res.J. 12006; 21(4): 485–492.

3. B. Kosikova, M.Duris, V.Demianova. Conversion of lignin biopolymer into surface-active derivatives. Eur. Polym. J. 2000; 36:1209–1212.

4. Compere, A.L., Grif.th, W.L., Leitten, Jr, C.F., Petrovan, S.. Improving the fundamental properties of lignin-based carbon fiber for transportation applications. Proc. International SAMPE Technical Conference, SAMPE 2004:217–225.

5. Danielson, B. and Simonsson, R.. Kraft lignin in phenol formaldehyde resin. Part 1. Partial replacement of phenol by kraft lignin in phenol formaldehyde adhesives for plywood. J. Adhes. Sci. Technol. 1998; 12(9): 923–939.

6. Elegir, G., Bussini, D., Antonsson, S., Lindstrom, M.E., Zoia, L.. Laccase initiated cross-linking of lignocellulose fibers using an ultra-filtered lignin isolated from kraft black liquor. Appl. Microbiol. Biotechnol. 2007; 77(4):809–817.

7. Fargues, C, Mathias, A., Rodrigues, A.. Kinetics of vanillin production from kraft lignin oxidation. Ind. Eng.Chem.Res.1996; 35: 28–36.

8. Gabrielii, I., Gatenholm, P., Glasser, W.G., Jain, R.K., Kenne, L.. Separation, characterization and hydrogel-formation of hemicellulose from aspen wood. Carbohydr. Polym. 2000; 43(4):367–374.

9. Gargulak, J.D. and Lebo, S.E.. Lignin: historical, biological, and materials perspectives. ACS Symp Ser 2000; 742:304–320.

10. Grondahl, M., Eriksson, L., and Gatenholm, P.. Material properties of plasticized hardwood xylans for potential application as oxygen barrier films. Biomacromolecules 2004; 5: 1528–1535.

11. Hannuksela, T., Holmbom, B.,Mortha, G., Lachenal, D.. Effect of sorbed galactoglucomannans and galactomannans on pulp and paper hand sheet properties, especially strength properties, Nordic Pulp Paper Res. J. 2004; 19(2): 237–244.

12. Hartman, J., Albertsson, A.-C., Soderqvist Lindblad, M., Sjoberg, J.. Oxygen barrier materials from renewable sources: material properties of softwood hemicellulose-based films. J. App. Polym. Chem. 2006; 100: 2985–2991.

13. van Heiningen, A.. Converting a kraft pulp mill into an integrated forest biorefinery. Pulp Paper Can. 2006; 107(6): 38–43.

14. Kadla, J.F., Kubo, S., Venditti, R.A., Gilbert, R.D., Compere, A.L., Grif.th, W.. Lignin-based carbon fibers for composite fiber applications. Carbon 2002; 40: 2913–2920.

15. Kubo, S. and Kadla, J.F.. Lignin-based carbon fibers: Effect of synthetic polymer blending on fiber properties. J. Poly. Environ. 2005; 13(2): 97–105.

16. Lasheras, J.C, Fernandez-Pello, A. C, Dryer, F. L.. Initial Observations on the Free Combustion Characteristics of Water-In-Fuel Emulsions. Combust. Sci. Technol. 1979; .21:1–14.

17. Lima, D.U., Oliveira, R.C., Buekeridge, M.S.. Seed storage hemicelluloses as wet-end additives m papermaking. Carbohydr. Polym. 2003; 52: 367–373.

18. Marcelo Cardoso, eder Domingos de Oliveira, Maria Laura Passos. Chemical composition and physical properties of black liquors and their effects on liquor recovery operation in Brazilian pulp mills. Fuel 2009; 88: 756–763.

19. Masato Mikami , Naoya Kojima. An experimental and modeling study on stochastic aspects of microexplosion of binary-fuel droplets. Proc. Combust. Inst. 2002; 29: 551–559.

20. Nada, A.M.A., Yousef, M.A., Shaffei, K.A., Salah, A.M.. Lignin from waste black liquors—II; different lignins in phenol formaldehyde resin. Pigment Resin Technol. 1999; 28(3): 143–148.

21. Olsson, M.R., Axelsson, E. and Berntsson, T„ Exporting lignin or power from heat-integrated pulp mills: a techno-economic comparison suing model mills. Nordic Pulp Paper Res. J. 2006; 21(4): 476–484.

22. S.A. Gundersen, J. Sjoblom, in: J. Sj0blom (Ed.), Encyclopedic Handbook of Emulsion Technology, Marcel Dekker, New York, 1999.

23. Sarkar, S. and Adhikari, B.. Lignin-modified phenolic resin: synthesis optimization, adhesive strength, and thermal stability. J. Adhes. Sci. Technol. 2000; 14(9): 1179–1193.

24. Sellers, T., Jr., McGinnis, G.D., Ruf.n, T.M., Janiga, E.R..Lignin-modified phenol-formaldehyde resin development for breboard. Forest Prod. J. 2004; 54(9): 45–51.

25. Soderqvist Lindblad, M., Ranucci, E., Albertsson, A.-C. Biodegradable polymers from renewable sources. New hemicellulose-based hydro gels. Macromol. Commun. 2001; 22:962–967.

26. Suk H. Chung, Joong S. Kim. An experiment on vaporization and micro explosion of emulsion fuel droplets on a hot surface. Symp. (Int.) Combust. 1991; 23(1): 1431–1435.

27. Toshikazu Kadota, Hajime Tanaka, Daisuke Segawa, Shinji Nakaya, Hiroshi Yamasaki. Microexplosion of an emulsion droplet during Leidenfrost burning. Proc. Combust. Inst. 2007; 31:2125–2131.

28. Villar, J.C., Caperos, A. and Garcia-Ochoa,F„ Oxidation of hardwood kraft-lignin to phenolic derivatives with oxygen as oxidant. Wood Sci. Technol. 2001;35: 245–255. Westbye, P., Svanberg,C, Gatenholm, P.. The effect of molecular composition of xylan extracted from birch on its assembly onto bleached softwood kraft pulp. Holzforschung 2006;60(2): 143–148.

29. Wising, U. and Stuart, P.. Identifying the Canadian forest biorefinery. Pulp Paper Can. 2006; 107(6): 25-30.

30. Yap, L. T, Lashea s, J.C, Dryer, f. L.. Effect of the ambient pressure on the explosive burning of emulsified and multicomponent fuel droplets. Symp. (Int.) Combust. 1985; 20 (1):1761–1772.

Acknowledgements

The authors are grateful to the Scientific & Technical Department, Jiangsu Province, PRC and the Changzhou Scientific & Technical Bureau, Jiangsu Province, P R C for financial support (grant GB2004023, CB20050080). Meanwhile we gratefully acknowledge project funding from the Heavy Oil Nation Laboratory open subject, the China University of Petroleum, Beijing, P R C (contract number, 2008–15).

Author information

Authors and Affiliations

Additional information

Published in revised form in Khimiya i Tekhnologiya Topliv i Masel, No. 4, pp. 27 – 30, 2011.

Rights and permissions

About this article

Cite this article

Xu, G., Yang, Jh., Mao, Hh. et al. Pulping black liquor used directly as a green and effective source for neat oil and as an emulsifier of catalytic cracking heavy oil. Chem Technol Fuels Oils 47, 283–291 (2011). https://doi.org/10.1007/s10553-011-0297-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-011-0297-9