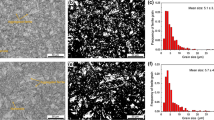

Studies are presented of helium porosity in EP-450 oxide-dispersion-hardened yttrium steel, obtained by electopulse sintering, as a function of the Y2O3 content in comparison with EP-450 matrix steel and dispersion-hardened steel fabricated by hot extrusion. It is found that multiple zones with different types of helium porosity and different zone distribution develop in steel with 1 wt.% Y2O3; in steel with 0.3 wt.% Y2O3, there are fewer such zones than in matrix steel and steel obtained by hot extrusion. It is proposed that the extremely nonuniform distribution of porosity over volume and size in steel fabricated by electropulse sintering is associated with the initially strongly defective structure, including residual porosity, as well as with the chromium redistribution between ferrite grains and tempered-martensite grains during the sample preparation process.

Similar content being viewed by others

References

I. A. Bogachev, I. I. Chernov, M. S. Stal’tsov, et al., “Optimization of electro-pulse sintering regimes for producing high-density dispersion-harden reactor steel,” At. Energ., 120, No. 1, 29–34 (2016).

I. Utke, P. Hoffmann, and J. Melngailis, “Gas-assisted focused electron beam and ion beam processing,” Vac. Sci. Technol. B, 26, No. 4, 1197–1276 (2008).

I. E. Chernov, S. Yu. Binyukova, B. A. Kalin, et al., “Behaviour of helium in steel Cr12W2VTaB under various implantation temperatures,” J. Nucl. Mater., 367–370, Pt. A, 468–472 (2007).

I. I. Chrenov, M. S. Stal’tsov, B. A. Kalin, and I. A. Bogachev, “Particulars of helium porosity formation in the surface layer of structural materials of the first wall of a thermonuclear reactor,” Metally, No. 2, 29–34 (2016).

I. I. Chernov, M. S. Staltsov, I. D. Nikolaeva, et al., “Influence of structural-phase state of ferritic-martensitic steels on the helium porosity development,” in: IOP Conf. Ser. Mater. Sci. Eng., doi:https://doi.org/10.1088/1757- 899X/130/1/012004.

S. Donnelly, “The density and pressure of helium in bubbles in implanted metals: a critical review,” Rad. Eff., 90, No. 1/2, 1–47 (1985).

ICDD International Powder Database, PDF-2, No. 86-1107, www.icdd.com.

Y. Xia, X. Wang, Z. Zhuang, et al., “Microstructure and oxidation properties of 16Cr–5Al–ODS steel prepared by sol–gel and spark plasma sintering methods,” J. Nucl. Mater., 432, 198–204 (2013).

Author information

Authors and Affiliations

Additional information

Translated from Atominaya Energiya, Vol. 124, No. 3, pp. 144–149, March, 2018.

Rights and permissions

About this article

Cite this article

Nikolaeva, I.D., Stal’tsov, M.S., Chernov, I.I. et al. Yttrium Oxide Concentration Effect on Helium Porosity Formation in Oxide-Dispersion-Hardened Ferrite-Martensite Steel. At Energy 124, 173–179 (2018). https://doi.org/10.1007/s10512-018-0393-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10512-018-0393-6