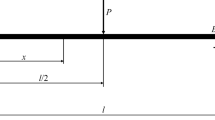

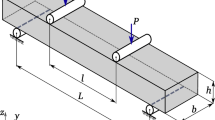

A method is proposed for determining the elastic modulus of a material from the results of bending tests performed on a prismatic sample using simultaneously the method of digital correlation of images for precise measurement of the displacements of points in the sample. This procedure was tested in three-point bending of steel and graphite samples. The effect of the ratio of the distance between the supports to the height of the cross-section of the sample on the reliability of the determined elastic modulus of the material is evaluated. The values obtained for the modulus of elasticity of steel and graphite agree with the characteristic values for the investigated materials when the ratio of the distance between the supports to the height of the cross-section of the sample is greater than 7.

Similar content being viewed by others

References

Y. G. Dragunov, S. V. Evropin, M. M. Gadenin, et al., “Kinetics of stresses and strains in the calculation of high-temperature strength and durability of reactor-structures,” At. Energ., 119, No. 3, 145–155 (2015).

A. M. Dmitriev, O. J. Kavun, M. G. Moshchenko, et al., “Investigation of thermal inertia and thermal stresses of heat-transfer elements in a nuclear reactor with solid coolant,” At. Energ., 110, No. 5, 273–279 (2011).

L. V. Sergeeva, “Numerical simulation of stress-strain state of the graphite blocks in the light of validation of RBMK life extension,” At. Energ., 104, No. 3, 157–160 (2008).

Release 16.2 Documentation for ANSYS, ANSYS Inc., Electronic Data and Software (2015).

NAFEMS Search Engineering Analysis and Simulation, FEA, Finite Element Analysis, CFD, Computational Fluid Dynamics, and Simulation, NAFEMS Ltd., Hamilton, United Kingdom (1984).

M. Sutton, J. Orteu, and H. Schreier, Image Correlation for Shape, Motion and Deformation Measurements, University of South Carolina, SC29208, USA (2009).

V. Y. Goltsev, E. G. Grigoriev, and A. V. Osintsev, “Evaluation of the uniformity of the material of articles produced by pulse high-voltage contact welding and spark plasma sintering,” Tekhnol. Mashinostr., No. 7, 71–75 (2016).

V. Y. Goltsev, Methods of Mechanical Testing and Mechanical Properties of Materials, MIFI, Moscow (2012).

E. N. Marmer, Carbon-Graphite Materials, Metallurgiya, Moscow (1973).

Author information

Authors and Affiliations

Additional information

Translated from Atomnaya Énergiya, Vol. 122, No. 5, pp. 277–282, May, 2017.

Rights and permissions

About this article

Cite this article

Gol’tsev, V.Y., Osintsev, A.V. & Plotnikov, A.S. Dependence of the Determined Value of the Elastic Modulus of a Material on the Ratio of the Distance Between the Supports to the Height of the Cross-Section of the Bent Sample. At Energy 122, 339–345 (2017). https://doi.org/10.1007/s10512-017-0276-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10512-017-0276-2