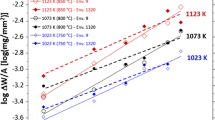

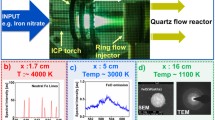

The release of the process gases H2, H2O, CO, CO2, and Ar from alloyed samples of uranium dioxide by oxides of Nb, Ce, Al, Si, and Fe has been studied by means of thermal extraction in vacuum at 1873 K. The niobium concentration in U1−yNbyO2 was 0.06–0.2 mass % (y = 0.001–0.004), the cerium content was 0–25 mass% (y = 0–0.3434), and the content of mullite or Indian red did not exceed 0.25 mass%, the oxygen potential Δ̄GO2 of the surface of the samples ranged from −400 to −300 kJ/mole at 1873 K. It was determined that the specific gas release from alloyed samples of uranium dioxide depends on the content of niobium, cerium, and impurity carbon as well as the porosity and the radial gradient of the departure from stoichiometry. A model is proposed for the physicochemical and diffusion processes accompanying the thermal extraction of gas from alloyed uranium dioxide.

Similar content being viewed by others

References

V. V. Gorskii, “Improvement of uranium fuel for light-water reactors,” At. Tekhn. Rubezh., No. 5, 3–12 (2000).

P. Dehaudt, C. Lemaignan, L. Caillot, et al. “New UO2 fuels studies,” in: Proc. IAEA Techn. Com. on Advances in Fuel Pellet Technology for Improved Performance at High Burnup, Tokyo, 28 Oct.–1 Nov. 1996, IAEA-TECDOC-1036, IAEA, Vienna (1998), pp. 27–40.

D. Ohai and M. Roth, “Sintered pellets obtaining for advanced fuel manufacturing,” in: Proc. IAEA Techn. Com. on Advanced Fuel Pellet Materials and Designs for Water Cooled Reactors, Brussels, 20–24 Oct. 2003, IAEA-TECDOC-1416, IAEA, Vienna (2004), pp. 133–146.

T. Matsuda,Y. Yusa, S. Kobayashi, and M. Toba, “Characteristics of fuel pellet with additive of Al and Si,” in: Proc. IAEA Techn. Com. on Advances in Fuel Pellet Technology for Improved Performance at High Burnup, Tokyo, 28 Oct.–1 Nov. 1996, IAEA-TECDOC-1036, IAEA, Vienna (1998), pp. 9–18.

K. Song, K. Kim, K. Kang, and Y. Jung, “Grain size control of UO2 pellets by adding heat-treated U3O8 particles to UO2 powder,” J. Nucl. Mater., 317, 204–211 (2003).

G. Marsh, G. Wood, and C. Perkins, “Niobia-doped UO2 fuel manufacturing experience at BNFL,” in: Proc. IAEA Tech. Com. on Advances in Fuel Pellet Technology for Improved Performance at High Burnup, Tokyo, 28 Oct. – 1 Nov. 1996, IAEA-TECDOC-1036, IAEA, Vienna (1998), pp. 19–28.

Y. Harada, “Sintering behavior of niobia-doped large grain UO2 pellet,” J. Nucl. Mater., 238, 237–248 (1997).

P. Sawbridge, G. Reynolds, and B. Burton, “The creep of UO2 fuel doped with Nb2O5,” ibid., 97, No. 3, 300–308 (1981).

H. Yoo, S. Lee, J. Kim, et al., “Densification behavior of TiO2 doped UO2 pellet,” in: Proc. IAEA Techn. Com. on Advanced Fuel Pellet Materials and Designs for Water Cooled Reactors, Brussels, 20–24 Oct. 2003, IAEA-TECDOC-1416, IAEA, Vienna (2004), pp. 113–124.

H. Assmann,W. Dorr, G. Grade, et al., “Doping UO2 with niobia – beneficial or not?” J. Nucl. Mater., 98, No. 1–2, 216–220 (1981).

R. Simmons, N. Lonts, J. Pritchett, et al., “Integral fuel burn able absorber experience in two-and three-loop cores,” ANS Transact, 53, 88–89 (1986).

D. Balestrieri, “A study of the UO2/Gd2O3 composite fuel,” in: Proc. IAEA Tech. Com. on Advances in Fuel Pellet Technology for Improved Performance at High Burnup, Tokyo, 28 Oct.–1 Nov. 1996, IAEA-TECDOC-1036, IAEA, Vienna (1998), pp. 63–72.

T. Restivo, A. Claudio, E. Silva., J. Pagano, “Effect of additives on the sintering kinetics of the UO2–Gd2O3 system,” in: Proc. IAEA Tech. Com. on Advances in Fuel Pellet Materials and Designs for Water Cooled Reactors, Brussels, 20–24 Oct. 2003, IAEA-TECDOC-1416, IAEA, Vienna (2004), pp. 147–154.

Yu. K. Bibilashvili, “Status of work on improving materials and fuel elements for VVER and RBMK reactors,” in: Abstr. of Reports at the Int. Conf. on “Atomic Energy at the Threshold of the 21st Century,” Elektrostal (2000), pp. 520–522.

J. Davies, S. Vaidyanathan, and R. Rand, “Modified UO2 fuel for high burnup,” in: Proc. of SFEN/ENS Conf. TOPFUEL 99, Paris (1999), pp. 385–395.

S. Aldavakhra, V. I. Savander, and N. I. Belousov, “Method for calculating and analyzing the application of granular absorbers in VVER,” At. Énerg., 100, No. 1, 8–13 (2006).

K. Une, “Simulated bubble swelling in UO2 pellets,” J. Nucl. Mater., 158, 188–201 (1988).

A. N. Anrianov, V. G. Baranov, E. G. Vakolyuk, et al., “Melting temperature of low-melting phases in plasticized oxide nuclear fuel,” Vopr. At. Nnauki Tekhn. Ser. Materialovedenie i Novye Materialy, No. 2(67), 139–144 (2006).

A. Romano, M. Horvath, and R. Restane, “Evolution of porosity in the high-burnup fuel structure,” J. Nucl. Mater., 361, 62–68 (2007).

V. G. Baranov, A. V. Tenishev, and A. V. Khlupov, “Gas release from pellets of model oxide fuel based on uranium,” Perspekt. Mater., No. 6, 36–45 (2008).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baranov, V.G., Tenishev, A.V. & Khlunov, A.V. Model representation of the physicochemical and diffusion properties during thermal extraction of gas from alloyed uranium dioxide. At Energy 107, 255–262 (2009). https://doi.org/10.1007/s10512-010-9223-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10512-010-9223-1