Abstract

The results of a complex of tests of refractories for glass resistance under static and dynamic conditions and the electric resistance during glass melting are presented.

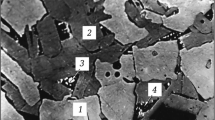

The tests of the refractories in a phosphate glass melt at 800–1100°C showed that the most stable material is the fusion-cast chromia-alumina-zirconia refractory ER-2161 with chromium oxide content 26 mass%. The pressed chromia-corundum refractory KhKT-10 possesses adequate glass resistance and is an electric insulator under the glass melting conditions in the ÉP-500 melter.

On the basis of the results of comparative tests of chromia-containing refractories and Bakor-33, the refractories ER-2161 and KhKT-10 are recommended for the masonry of future furnaces as a material for the bridgewall and the electric-insulation layer in a two-layer threshold.

Similar content being viewed by others

References

A. S. Polyakov, G. B. Borisov, N. I. Moiseenko, et al., “Experience in operating the ÉP-500/1R ceramic melter for vitrifying liquid high-level wastes,” At. Énerg., 76, No. 3, 183–188 (1994).

O. N. Popov, Corrosion and Operation of Refractory Materials in Tank Glass Melting Furnaces with High Glass Melting Temperatures, VNIIÉSM, Moscow (1974).

Author information

Authors and Affiliations

Additional information

__________

Translated from Atomnaya Énergiya, Vol. 102, No. 3, pp. 174–177, March, 2007.

Rights and permissions

About this article

Cite this article

Borisov, G.B., Volchok, Y.Y., Pastushkov, V.G. et al. Tests of new refractories for the masonry of the ÉP-500 ceramic melter. At Energy 102, 211–216 (2007). https://doi.org/10.1007/s10512-007-0031-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s10512-007-0031-1