Abstract

Seaweed is seen as a promising future source of biomass, and significant efforts are taken to upscale seaweed aquaculture production in Europe. Despite regulatory frameworks for food safety, environmental safety, and occupational health and safety applicable to seaweed production, a major barrier to upscaling production is the lack of commonly accepted, uniform frameworks for safety assessment. As a consequence, efforts to deal with food safety, environmental safety, and occupational health and safety are fragmented. Based on a literature review and consultations with stakeholders, this paper introduces a generic protocol on how to approach safety of the production of seaweed. A prototype version of the generic protocol was evaluated in a practical setting in Norway. Results show that a consistent, structured approach to safety makes it possible to identify hazards and prioritize and collect data on key hazards. The protocol facilitated a sector discussion on safety, providing a shared discourse to talk about safety. It must be acknowledged that the farming and processing practices and the location of cultivation strongly influence which hazards are most relevant. The protocol succeeded in bringing focus to data collection, putting effort into the analysis of hazards considered most relevant in a practical setting.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Seaweeds are seen as a promising resource, offering biomass for food and other applications. Cultivation of seaweed can help address contemporary challenges such as environmental degradation, loss of biodiversity, and climate change (Hasselström et al. 2020; Duarte et al. 2021; Yong et al. 2022; Rebours et al. 2014). The potential of seaweeds is acknowledged by the European Commission through EU4Algae, a forum for collaboration among European algae stakeholdersFootnote 1, emphasizing seaweed’s important role as a source of alternative protein for a sustainable food system in Europe and global food security.Footnote 2 Subsequently, European Union (EU) initiatives such as the Farm to Fork strategy, the Blue Bioeconomy Forum, and the Renewable Energy Directive call on community action to better utilize the potential of algae. The EU Joint Research Council collects data on the size and characteristics of the EU seaweed sector (including, among others, Norway), concluding that in 2022, 194 companies were active in the EU seaweed sector. The UK also sees renewed interest in seaweed production. Currently, the European seaweed industry is mostly comprised of small scale enterprises that either cultivate or harvest seaweed (Vazquez Calderon and Sanchez Lopez 2022). Two-thirds of the companies producing seaweed in Europe rely on wild harvesting, although investment opportunities and increase in demand has led to a rise in the number of small farms cultivating seaweed (Vazquez Calderon and Sanchez Lopez 2022; Kuech et al. 2023).

As the European seaweed aquaculture sector expands (Araújo et al. 2021), there is growing attention given to the possible drawbacks of upscaling seaweed aquaculture. From a food safety perspective, the debate on the impact of seaweed consumption on human health is characterized by a spectrum of standpoints. On the one hand, it is argued that seaweed can be a valuable contribution to diets, providing essential minerals (Lozano Muñoz and Díaz 2022; Shannon and Abu-Ghannam 2019). On the other hand, there are concerns about the accumulation of certain minerals in seaweed, resulting in potentially negative health impacts of seaweed consumption (Lozano Muñoz and Díaz 2022; FAO and WHO 2022; Banach et al. 2020). A similar juxtaposition is visible when it comes to environmental impacts. Reported positive impacts, among others, are biodiversity enhancements (Radulovich et al. 2015; Duarte et al. 2021), climate change mitigation (Chung et al. 2013; Yong et al. 2022; Froehlich et al. 2019), and nutrient remediation (Jiang et al. 2020; Xiao et al. 2017; Racine et al. 2021). Concerns are also voiced about the facilitation of disease, impacts on population genetics, and wider alterations to the physiochemical environment (van der Meer 2020; Campbell et al. 2019; Tonk et al. 2021).

OHS management in micro and small enterprises (MSEs) can be problematic, and evidence suggests that non-standard types of employment are not uncommon either (EU-OSHA 2018). Published work on how health and safety are organized in seaweed MSEs and start-ups in Europe is sparse, and little is known about the support and advice these companies receive as well as whether compliance with OHS regulations is properly monitored. There is a lack of information on the seaweed industry workforce, with literature focused on occupational health and safety (OHS) in the sector also limited. Work conditions in aquaculture, generally, and the seaweed industry more specifically, vary, and consequently, OHS risks can also vary depending on the location, cultivation type, or species cultivated (Cavalli et al. 2019; Wilding 2021; Fry et al. 2019; Holen et al. n.d.).

Furthermore, Cai et al. (2021) emphasized that “seaweed cultivation usually entails a large amount of labor in planting, daily maintenance, harvesting, and post-harvest handling, with a seasonal or occasional demand (e.g., a large number of workers are needed for a short time period to harvest seaweeds at the optimal time to ensure desirable quality).” Precarious employment can lead to poorer OHS management arrangements and outcomes (Quinlan et al. 2001; Quinlan and Bohle 2009). Although it is known that subcontracting and informal employment have grown in aquaculture (Cavalli et al. 2019), literature on employment types within seaweed SMEs currently operating in Europe is sparse. Seaweed price volatility can be passed down the value chain to small-scale seaweed farmers and affect prices charged by suppliers. It has been reported that health and safety in small firms are influenced by the lack of investment to improve working conditions when downward price pressures are driven by buyers (James et al. 2007; Walters and James 2011).

Concerns about the safety of seaweeds as food (van der Spiegel et al. 2013; van Hoof et al. 2020; Sá Monteiro et al. 2019; Mateo et al. 2020; Wood et al. 2017), environmental impacts of large-scale cultivation (Campbell et al. 2019; van der Meer 2020), and OHS impede further growth of the sector. To date, a clear and specific approach to the identification, prioritization, and assessment of seaweed risks, and an approach that works for the small and medium enterprises (SMEs) in the EU sector, is inadequate. Legislation related to this sector is largely covered by directives (e.g., MSPD 2014/89/EU, MSFD 200/60/EC, ASR 2014/1143/EU). When considering safety for food and feed applications, an overview of legislation has been given by Banach et al. (2020). All do cover parts of the seaweed production chain, but substantial data gaps are present and should be further addressed. Although existing frameworks for (marine) risk assessment have safe and unsafe operating practices codified into protocols and standards, such as the International Maritime Organizations Formal Safety Assessment Framework (Kirk and Thompson 2021; Asuelimen et al. 2020), these tend to build on sector-specific experiences (van Hoof et al. 2020). Seaweed aquaculture activities in Europe are, in comparison to Asia, in their infancy and hence do not yet come with a history of experiences, but those involved do, of course, bear responsibility for safety (Banach et al. 2020; Campbell et al. 2019).

The main objective of the Safe Seaweed by Design project reported in this paper was to develop a generic protocol that can support the seaweed sector by stimulating an evidenced debate on the safety of seaweed production. For this, the following sub-questions were addressed in this study:

-

What would a prototype protocol to support the seaweed sector to discuss safety look like considering the current state of the seaweed sector?

-

How was the prototype protocol evaluated in the practical setting?

-

What are the lessons learned for implementing the protocol in practice?

-

What do the lessons learned tell us about managing safety in the seaweed sector?

The aim of the study was to develop a risk protocol that is beneficial to a professional debate between seaweed producers, seaweed buyers, and other stakeholders in the seaweed food value chain, with a focus on three dimensions: food safety, environmental safety, and OHS. Along with the discrepancies with terms like hazards and risks, the term risk assessment can also cause confusion between disciplines and stakeholders, also for seaweed farmers. This discrepancy has been reported for growers in the produce food chain. As a result, Monaghan et al. (2017) developed an alternative approach, namely, a structured qualitative grower seaweed farmer risk assessment, to communicate, in a simplified way, the needs for food safety for primary producers. Our generic protocol follows a similar approach for the seaweed sector, with a seaweed farmer risk assessment. The nuance in our protocol is that safety encompasses more than one scientific discipline and is targeted at seaweed cultivation in the EU.

The term “protocol” is commonly used in discussions on safety in various domains, including food safety, maritime safety (Nawrot and Pepłowska-Dąbrowska 2020; Knapp and Franses 2010), and OHS (Indrayani et al. 2022). In legal terms, the term protocol is commonly used for agreements that are less formal than those entitled “treaty” or “convention.” Our definition of protocol builds on this non-legal status; the protocol is defined as an outline of good practices in relation to food safety and environmental safety when producing seaweed. A protocol can also be defined as “a system of rules that explain the correct conduct and procedures to be followed in formal situations.”Footnote 3 To distinguish from protocols that provide more detailed guidance on, for example, sampling, trials, or experiments (Lee and Chae 2021; Schreier et al. 2022), we use the term “generic protocol.”

This research focused exclusively on the relatively young seaweed aquaculture industry in Europe. The study focused on the use of seaweeds for food, acknowledging that other applications of seaweed (such as biomaterial) might come with different requirements. The analysis focused particularly on concerns during seaweed farming (i.e., wild seaweed cultivation was out of the scope), particularly the use of Saccharina latissima and Alaria esculenta.

Methods

The project developed a generic protocol and tested it in a case study, which was then evaluated afterwards, following the principles of prototyping (Camburn et al. 2017; Groth and Seipold 2020; Venable et al. 2012). The prototype protocol was initially based on a review of available literature and on consultation with stakeholders. Scientific prototyping is a user-focused and evidence-based framework. The main goals are observation, the definition of ideas based on user needs, and sharp validation or disproval of the ideas aiming to deliver and launch quality products (Galindo Bello 2018).

Protocol development

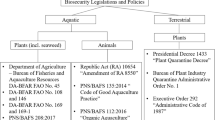

At the start of developing a prototype protocol, the study team conducted a literature review and stakeholder consultation to identify how seaweed safety is dealt with, identify existing frameworks and protocols, and identify lessons learned to move forward in drafting the generic protocol (Fig. 1). These results had been published (Banach et al. 2022) and were then further used in this prototype protocol.

Literature review

The literature search on food safety aspects served to identify hazards in two types of seaweeds when consumed as food (i.e., what kind of agents cause an adverse effect on health when ingested by humans). Literature was searched in Scopus and Web of Science for publications over the last 5 years. Search terms were built up in three search strings: (1) seaweed, (2) “Food OR ‘human consumption,’ and (3) ‘food safety’ OR hazard* OR ‘adverse effect*’ OR risk*.” These search terms were searched for in the abstract, title, and keywords of scientific articles. Further details on the methodology applied in this review are provided in the project publication by Banach et al. (2022).

The initial literature search for environmental safety and OHS was based on keywords and phrases identified in relation to these topics and included both truncated variations and combinations of terms. Searches were carried out in the Google Scholar database and were limited to the period 2011 to 2021 and articles written in English. The relative scarcity of relevant OHS literature meant that further databases and an extended time period were used for this area of the project. A review of the literature relating to OHS experiences and the management and regulation of OHS within the aquaculture sector, more broadly, was carried out in August 2021. Also reviewed were online resources, official statistics, or reports published by governmental agencies, professional associations, universities, national or international organizations, institutions, and bodies. These were related to OHS, aquaculture, and/or seaweed cultivation.

References used in previous reports that focused on seaweed farming were reviewed to gather further insight into the environmental safety of seaweed. From there, additional sources were selected, keeping in mind literature from the past 5 years. Search terms related to seaweed farming or production and seaweeds (laminaria, Saccharina latissima, etc.) were used. When needed, snowballing of literature was performed.

Search results were subject to a two-stage process for all three disciplines. First, manuscript titles were read, and any papers which were clearly irrelevant were discarded. Second, abstracts of the remaining articles were read, and again papers that were not relevant to the project were discarded. The papers that were retained after both of these stages were downloaded into a reference management software package and reviewed in full. To gather further insight into the environmental safety of seaweed, we performed snowballing of literature, starting with the references used in previous reports that focused on seaweed farming. Finally, when required, personal experience from working directly in the seaweed sector and scientific expertise on this topic were used to determine the relevancy of the papers retrieved.

Exploratory interviews

Exploratory interviews were conducted with experts on seaweed and food safety (one processor, two seaweed consultant, one academic researcher, and one producer). A second round of interviews was carried out with 12 companies, farming, processing, and/or selling seaweed, to identify hazards related to food safety, environmental safety, and OHS and to provide additional insight into them. The methodology of how the interviewees were chosen is described in detail in the above mentioned earlier project publication (Banach et al. 2022).

In addition, further interviews were carried out to map the structure and organization of work and employment in “new” seaweed cultivation areas. Eight additional interviews were conducted with seaweed owners/managers, workers, and stakeholders in the seaweed industry; these were supplemented with twelve informal email discussions with seaweed owners/managers and stakeholders in the seaweed industry. Three different discussion guides were developed, which were emailed in advance to the interviewees with a document that provided information about the study and the planned use of data and a consent form. The discussion guide included questions about the seaweed sector in general, workplace/enterprise size, the type and length of work contracts, tasks, work hazards including stress and fatigue, health and safety management systems in place to protect from these hazards, incidents at work, and supply chain influence. The interviews were recorded and transcribed.

Based on the acquired insights and analysis of existing safety standards, the team developed a prototype protocol for food safety and environmental safety. We tested a prototype of the generic protocol in consultation with Arctic Seaweed. An alternative approach was taken for OHS, focusing less on hazards and their mitigation but rather on better understanding the day-to-day worker experience of OHS risks and arrangements for their management by those involved in seaweed cultivation, in particular those risks that may lie outside direct physical, chemical, or biological hazards.

Design principles

The generic protocol was developed to be used in the different steps in seaweed farming as well as different aspects that relate to health and safety issues that may be encountered, such as food safety, maritime safety, and environmental safety. Inspired by other protocols (van Hoof et al. 2020) and based on literature and consultation of stakeholders (Banach et al. 2022), the following design principles for a generic safety protocol were identified:

-

(i)

Hazards and risks may be confusing terms used differently in various disciplines. In addition, seaweed-related risks can be complex, uncertain, and ambiguous (van Hoof et al. 2020; van den Burg et al. 2020). A shared understanding across scientific disciplines and stakeholders is needed.

-

(ii)

There is a limited accumulated experience in dealing with safety in the European seaweed sector (Campbell et al. 2019). However, the seaweed sector is long withstanding in countries outside of the EU. The protocol should facilitate a process to come to a uniform approach for dealing with safety.

-

(iii)

The availability of reliable methods for seaweed farmers to use to collect data and assess the risk should be considered.

-

(iv)

Prioritizing the hazards and eventual risks to focus on is important given the prevalence of MSEs in the EU seaweed sector (Araújo et al. 2021); a specific aim of the generic protocol is to follow an approach that helps to focus on a limited number of hazards.

The practical setting: Arctic Seaweed

Arctic Seaweed is a Norwegian seaweed producer cultivating brown seaweeds along the Arctic Ocean. In 2021, they had three operational sites making use of a submerged modular and vertical system for farming seaweed. At two of these sites, Saccharina latissima was farmed, while at the third, Alaria esculenta was farmed. A notable design process implemented by Arctic Seaweed is an integrated harvesting and processing principle. This means that both harvesting and processing of seaweed occur on the vessel. Arctic Seaweed also uses the same vessel for the deployment and collection of seaweed. During deployment, the seeded lines are submerged. For a farm needing about 16,000 m of substrate, this design expedites the seeding process, with about 1 day required to deploy and seed the lines compared to about 1 week for traditional deployment and seeding of vertical, long lines. Arctic Seaweed’s design includes the full integration, mechanization, and onboard processing of seaweed. Cultivation is done with a modular, vertical approach, providing increased area efficiency in terms of producing seaweed. Besides the integrated harvesting and processing principle set up in their ship-based operations, Arctic Seaweed also further processes the seaweed (wet) at their production facilities.

Data was collected at Arctic Seaweed facilities between March 2022 and September 2022. A pre-installation ROV survey was already conducted in October 2021. The experiences in how these data were collected were also evaluated.

Stakeholder workshop

A stakeholder workshop was held as a hybrid event (combining in-person and on-line participation) in Bremerhaven, Germany, on 28 June 2022, prior to the Seagriculture EU 2022 conference, to get feedback on the protocol prototype. Information on the event has been disseminated through the Seagriculture EU 2022 conference program, the Wageningen University & Research website, Linked In, and the Safe Seaweed Coalition.Footnote 4 In addition to the 12 project team members that attended, there was one live participant and five online participants. The external participants had a mix of private, academic, and public sector experience. Attendees brought expertise from working in multiple organizations. For example, out of the external participants:

-

Three participants worked for or have founded seaweed production companies.

-

One participant worked for a university.

-

One participant worked for an organization that supported private enterprise development and inward investment.

-

Two participants had previous experience in developing seaweed quality assurance standards for government or certification organizations.

-

The countries represented by the participants were Canada, Scotland, and Malaysia.

Evaluation of the generic protocol in a practical setting

A structured evaluation was carried out after applying the protocol in the practical setting to identify lessons learned. Evaluation is a systematic assessment of the design, implementation, and outcomes of an intervention. It involves understanding how an intervention is being, or has been, implemented and what effects it has, for whom and why. Such evaluations look to identify what can be improved and estimate a project’s overall impacts, effectiveness, and efficiency. The evaluation of the practical setting represents a post-project evaluation. The evaluation was completed through the following steps:

-

(1)

Document review by the evaluation facilitator who, in order to bring a fresh perspective to the evaluation, was not involved in practical delivery.

-

(2)

Two internal workshops with the delivery team to evaluate the delivery process:

-

(a)

The first workshop was with the project coordinators, environmental safety specialists, OHS specialists, and an Arctic Seaweed representative.

-

(b)

The second workshop was with project coordinators, food safety specialists, and an Arctic Seaweed representative.

-

(a)

-

(3)

Follow-on interviews with representatives from monitoring equipment providers SATPOS and Rådgivende Biologer to identify lessons learned from deploying the equipment on site.

-

(4)

Clarifying discussions by email and telephone to ensure the accuracy of the evaluation.

Results: the generic protocol

The next sections discuss the concept of the protocol before introducing the principles underlying the design of the generic protocol and its application in a practical setting.

Seaweed production consists of a number of stages in production and processing, each with its own hazards. The production of seaweed at sea augments concerns about safety aspects. A few studies have investigated risk governance and frameworks to assess food safety risks when considering seaweed cultivation. These studies examined a combined — or multi-use approach — of seaweed cultivation at a wind farm. First, van den Burg et al. (2020) addressed risk governance, indicating that governance includes formal institutions and regimes. These refer to the totality of actors, rules, conventions, processes, and mechanisms concerned with how relevant risk information is collected, analyzed, and communicated and how regulatory decisions are taken (Dreyer and Renn 2009; Renn and Klinke 2015; Van Asselt and Renn 2011). The SOMOS study (van den Burg et al. 2020) concluded that “current risk governance for multi-use is poorly equipped to deal with the systemic nature of risks.” This means that the complexity of risk needs to be refined for multi-use concepts where seaweed cultivation is included. One could also extrapolate that a layer of complexity of the risk remains in non-multi-use or co-location settings,Footnote 5 given the multiple stakeholders involved along a food chain as well as the multiple disciplines involved with safety. Van den burg et al. (2020) advocated that an adaptive, flexible, and inclusive framework for risk assessment is required to deal with the complexity of risks. Moreover, the notion of risk communication and inclusion of stakeholders is brought to the forefront, the former of which is also advocated in the food safety risk analysis approach (Frewer 2000; Nayak and Waterson 2019). In our generic protocol developed, these principles are also applied.

Based on the design principles presented above, the literature review, and expert consultation, the following generic protocol was developed (see Fig. 2). The generic protocol consists of five steps that together contribute to a shared understanding of the hazards and risks, the prioritization and seaweed farmer risk assessment of remaining hazards, and the next steps to take for a seaweed farmer risk assessment.

The transparent application of this generic protocol makes it clear what hazards are to be taken into account, which ones are prioritized, and which ones should be assessed in detail in a seaweed farmer risk assessment.

Applying the generic protocol prototype

The next sections explain each step of the generic protocol and describe how it was implemented in a practical setting. Acknowledging that the generic protocol needs to be tailored to a specific situation, the experiences gained in a practical setting were valuable in critically assessing the protocol, identifying practical issues in seaweed farmer risk assessment, and formulating recommendations.

Step 1: familiarize

The objective of this first step is to ensure a good start to the process, warranting all involved are on the same page. The concepts used in discussions on safety are prone to personal perception and interpretations (Marshall 2020; Gurgis et al. 2022; Glette-Iversen et al. 2022), and the role of a safety professional is dependent on institutional and relational factors (van Wassenhove et al. 2022). In this context, the first necessary step is to come to a shared understanding of key concepts used when dealing with safety.

How was it applied in a practical setting?

We aimed for a shared understanding of key terms, including those like hazards and risks, by means of a shared glossary. In developing the glossary, we used commonly accepted definitions from the FAO, along with those from other governmental organizations like the European Food Safety Authority (EFSA). For example, a hazard can be something that has the potential to harm you, while risk is the likelihood that the hazard causes harm.Footnote 6 Besides hazard and risk, it is important to understand the risk analysis approach. The approach is a well-established model that illustrates a process toward “effective and transparent decision-making” of risks.Footnote 7 It comprises three parts: risk assessment, risk management, and risk communication. The process is often depicted as interdisciplinary. Evaluations are scientifically based — the risk assessment component and policy-based — the risk management component. The surrounding discussion on these components represents an interactive exchange of information on the risk between risk assessors, risk managers, and other relevant stakeholders.

Step 2: identify hazards

The objective of the second step is to identify the potential hazards in order to come up with a long list of potentially relevant hazards. In this step, the identification is key — not the prioritization of hazards. To identify hazards, scientific literature, public databases, and accumulated experience, e.g., with risk management, can be consulted. For established sectors, national or international guidelines such as the Codex Alimentarius, the EFSA’s scientific assessment practices, and the Food and Drug Administration provide specific directions on relevant food safety hazards that can be used. At the time of writing, the step should be based on a review of relevant publications (FAO and WHO 2022) and expert judgment. Environmental assessment (such as conducted under the EU Marine Strategy Framework Directive) and environmental impact assessment can be instrumental in identifying key environmental issues.

How was it applied in a practical setting?

The literature review and interviews resulted in a long list of non-prioritized hazards for food and environmental safety. For OHS, it was important to understand the wider context in which seaweed companies operate, the structure and organization of work as well as how safety is managed. The extended literature review and mapping of the seaweed industry, followed by discussions with producers, workers, and stakeholders, identified a number of issues relating to OHS in the seaweed industry.

Step 3: assess relevance and priority

In order to take the next step from a non-prioritized longlist of hazards to a selection of relevant hazards, it is necessary to identify which hazards are (a) relevant and (b) a priority in this study from the perspective of a seaweed farmer. This step is influenced by a number of factors. First, determining the local site conditions, including physical and environmental conditions, which hazards are relevant, e.g., the presence of contaminants in the environment influences food safety hazards, and how, for instance, water depth may influence the chances of impact on the seafloor and consequently environmental safety. The production system used is the second factor, taking into account the materials used, constructions used, and density of farming. Third, the relevance of hazards for food safety, environmental safety, and OHS is dependent on the seaweed species cultivated. The demands of stakeholders should be considered here as well, including governmental regulation and food, environmental, and OHS standards required by buyers of the seaweed produced. Lastly, the wider context in which companies operate (such as enterprise size) can be influential, and, particularly for OHS, employment arrangements should also be taken into consideration.

The tension of the cultivation ropes is a prime criterion for the entangling of other species. The density of the cultivation and the distance of the ropes influence several factors: impact of shading, risks when boats pass in between for monitoring or harvesting, or potential local nutrient competition for other species. But here again, the local environmental conditions are very closely related to the hazards becoming a risk or not. Currents and water depth will, for instance, allow one cultivation structure to bear no risk in one location but will have negative effects in another. That is why the hazards, also from the cultivation structure and not only from the farming practice itself, need to be assessed according to the local conditions.

How was it applied in a practical setting?

Since the prioritization of hazards will be based on both the impact of the hazard and the practical considerations for this research project, the ranking was conducted in two steps. In the first step, a ranking by a wide range of individuals involved in the seaweed sector through a survey was performed. Secondly, in-depth sessions with experts and project members were organized to discuss the analytical feasibilityFootnote 8 of the hazards and how relevant they are to the project (i.e., how they “fit” Arctic Seaweed’s cultivation site) as criteria for hazard selection. After having received the survey results, the study team organized a working group session to analyze the present hazards for analytical feasibility and relevance, given the practical setting. Whenever external input regarding a specific hazard was needed, external experts were consulted through interviews.

Step 4: prevent and mitigate

The next step in the generic protocol encompasses the prevention and mitigation of risks. The most important risks to be addressed by the farmer are selected, and mitigation strategies are developed. There may be low-hanging fruits, i.e., hazards that can be prevented from becoming risks by making changes in the production process that could immediately be taken. There could already be information, e.g., from permitting or where regulation considered this will not be a problem. Other risks may not be prevented completely, but important steps to mitigate the impact can be taken.

Many hazards that a seaweed farmer may encounter are influenced by the environment of the cultivation site. Therefore, when planning to cultivate seaweed, we recommend considering the site selection as well as in relation to the seaweed species to be cultivated. During such a seaweed farmer risk assessment, one should map out where hazards could be introduced, how these may be increased, reduced, or remain present, and how hazards could be prevented or mitigated for each step in the seaweed value chain. Also, although seaweed processing may lower the levels or concentrations of some hazards, it can be a source of cross-contamination or re-contamination if proper hygiene and sanitation are lacking. Thus, it is also essential to maintain good hygiene practices along the seaweed food value chain. There are environmental hazards affiliated with seaweed farming which, especially on a larger scale, can permanently damage the environment. Most are manageable, and mitigating measures should be developed and implemented. OHS hazards can extend from the acute and physical to the latent and psychosocial, and those related to the structure and organization of work and employment.

How was it applied in a practical setting?

Through several discussions with the seaweed cultivators of Arctic Seaweed, it became clear what preventative measures were already taken. Littering and fouling in the environment can mostly be resolved by good practices, e.g., making sure all equipment is secured and losses of waste are minimized. Too much noise disturbance is avoided by using the boat only on a few days, and only when necessary, ropes are under tension which avoids the entangling of larger species. They also processed the seaweed to lower the arsenic and iodine content and implemented good aquaculture practices to avoid contamination of the water with, for instance, viruses. First, incoming data from measurements undertaken did allow some insights, such as when fermentation is included in the production process, it leads to greater variation within batches meaning sampling strategies should account for this greater variety of outcomes. The use of non-toxic or non-harmful compounds can be made mandatory and could be written on lists as being accepted in the usage of seaweed farming. By using ROV imaging, a better insight can be generated for the farmer to assess the major littering origin. When a new system for seaweed cultivation is to be developed, it could be proposed to do a video survey to find the weakest links in the farm structure and replace those compounds with stronger parts.

When concerning the practical setting to be used to test the generic protocol, frequent, two-way communications with their workers occurred, which involved open discussions on health and safety; these include, for example, daily morning meetings during busy periods, where workers were encouraged to ask questions and voice concerns. However, interviews with owners/managers and workers of seaweed farms suggest that many companies do not involve their workers in discussions around OHS, with workers being the recipients of the information. Also, risk management measures generally do not extend to psychosocial or indirect/non-acute risks and enforcing authorities often lack resources to monitor OHS conditions. Other factors that can affect OHS are the complexity of the industry, lack of research on how to improve working conditions, precarious employment, price volatility, and small company size. Following those findings, a set of recommendations to the industry as a whole was produced, rather than solutions on how to prevent and mitigate specific hazards.

Step 5: seaweed farmer risk assessment

The objective of this final step is to conduct qualitative and/or quantitative seaweed farmer risk assessment of the remaining hazards. To collect data, specific protocols for data collection need to be developed to ensure that data collection gives a reliable picture of the hazards studied. New data collection is demanding, and existing data should be used where possible as it can provide meaningful insight into local conditions that impact the assessment.

How was it applied in a practical setting?

In the project, a number of key hazards were prioritized to be analyzed during the pilot. Methods for data collection and/or evaluation were recorded (Table 1). Data collection focused on food safety and environmental safety.

For food safety, sampling strategies were tested on the seaweed Saccharina latissima for representative metals, other elements like iodine and selenium, the allergen tropomyosin, and microbiological pathogens (Bacillus cereus, Salmonella spp., Vibrio spp., and norovirus). Arsenic speciation between organic and inorganic forms was also performed. Seaweed samples were collected during the harvest, from May 2 to 5, 2022, and analyzed by several analytical laboratories in Norway. When possible, accredited methods were used.

Out of a list of 22 potential environmental hazards, four hazards were selected for a field assessment. On the selected site, both Saccharina latissima and Alaria esculenta were cultivated. The selected hazards concern littering by the unintended release of materials, shading caused by the presence of a seaweed farm, disturbance of the seabed, and nutrient depletion as a result of nutrient uptake by cultured seaweed.

Additionally, the study made use of a combination of sensors to get online insight into water temperature (°C), salinity, pH, dissolved oxygen levels (mg/l), and sunlight (lux). These sensors are more related to information valuable for seaweed production rather than the assessment of hazards.

Evaluation and discussion

The evaluation concluded that the generic protocol was useful in identifying the most relevant hazards and bringing focus to further data collection. Through the application in a practical setting, a number of lessons were learned, and implementable recommendations were identified.

Lessons learned and recommendations relevant to seaweed producers

The following recommendations on a micro/company level focus on how to adapt the generic protocol for specific needs and how to plan for safety management for food and environmental safety. They also stress the importance of timing for measurements and sampling and how to best utilize already available data. Lastly, they also advice on the inclusion of workers when designing OHS approaches.

The generic protocol is a steppingstone toward specific protocols

The specific farm set-up co-determines which hazards and/or risks are most relevant for food and environmental safety. While generalized protocols can be designed, each industry actor will need to adapt their protocols to the specific needs of their seaweed value chain.

Industry actors should discuss the sampling requirements in more detail with the laboratories that will undertake the analysis to understand the laboratory’s expectations and their capabilities (e.g., which accredited methods are available, what form the seaweed should be delivered, etc.). The feedback related to the food safety protocol shown during the workshop was diverse. Participants generally recognized the need to monitor some food safety hazards routinely, e.g., in the form of a laboratory-supplied “package” of analysis. The participants acknowledged the presented prioritized hazards for seaweed, and no additional hazards were suggested, but it was also explained that often the seaweed producers analyze the seaweed with a “full package” from the laboratory they work with. Sometimes one is limited to the capabilities of the laboratory. The results of the discussions should be integrated into a site-specific sampling plan.

There are inherent trade-offs when selecting which parameters to measure and the level of assurance that is needed. For example, some product applications may need greater risk assurance than others.

Planning for safety management

Once protocols for food and environmental safety are established for each seaweed production site, fewer resources are required to undertake the analysis required as it will be about carrying out the analysis instead of designing the protocols. This could make monitoring significantly more cost-effective. Development of effective safety protocols will likely be iterative for each production site as location-specific lessons are learned from year to year.

There may be opportunities to combine safety monitoring with monitoring focused on optimizing production yield. Safety monitoring should be integrated into the operation and maintenance plan to ensure minimum disruptions to the seaweed harvest timetable.

Timing is crucial

Relevant moments for sampling and setting up monitoring start before the growing phase to capture the impact during the growth phase. Some measurements are comparatively with and without seaweed; thus, missing the “before growth phase” measurements makes the comparison impossible. Seaweed farming is praised for not needing much maintenance once infrastructures and growth lines are out in the water. Yet this also means that once it is deployed in the water, there is not much to be mended or changed. This limits the number of moments where one can mitigate or collect data.

Use available data when possible

A lot of data is necessary to conduct a seaweed farmer risk assessment for food, and environmental safety is already out there and available for use. Local authorities might measure the quality of the water already regularly for other industries, or other industries have already mapped out the bathymetry of the area for their own assessments, or scientific research projects might have measured other data, like quantitative or qualitative biodiversity in the area, that can be used when possible or available. Some of the measurements for the seaweed farmer risk assessment are costly or time-consuming. It can be worth looking at existing data and if it could be meaningful to propose collaborations with other maritime sectors for regular measurements.

Participatory OHS management systems

For OHS, our recommendation on a farm-micro-level is that owners/managers involve their workers (permanent and temporary) and/or representatives when they design approaches to OHS. These approaches would include regular risk assessments, provision of adequate and well-maintained PPE, and training received during induction but also through refresher courses throughout employment.

Lessons learned and recommendations relevant to the wider seaweed sector

While the generic protocol was developed to support the private sector in dealing with seaweed safety, the important role of the wider seaweed sector, including regulators and supply chain, in risk management became apparent when developing and evaluating the protocol. These actors play a pivotal role in ensuring safety is addressed in development of the seaweed aquaculture sector. The following recommended actions are identified.

Tailored guidance

It is important to acknowledge that, consistent with the findings of the literature review, owner-managers of start-ups and MSEs across industry sectors often struggle to recognize, understand, and comply with safety requirements (Legg et al. 2015). This reflects a lack of resources, including those related to funds, time, and in-house expertise. Owner-managers are frequently managing all aspects of their business, from accounts to marketing, and as our findings also suggest, these competing demands can mean that safety is afforded a relatively low priority. Research from other sectors further suggests that in these circumstances, a sector-specific guide to safety management in practice, delivered in an accessible format and supported with individual advice, is most likely to achieve effective compliance among such enterprises.

Joined-up approach to safety

Furthermore, safety is commonly the regulatory responsibility of more than one government agency which may lack resources to enforce regulations (Watterson et al. 2019). For example, in the UK, the Health and Safety Executive has reduced the number of its inspections, focusing mostly on hazardous industries, which would decrease visits to MSEs (EU-OSHA 2018). In order to maximize reach, the various bodies ensuring licensing and regulatory compliance for food safety, environmental safety, and OHS could offer coordinated support in all of these areas when any of them come into contact with seaweed companies. Advice offered could help especially those companies that struggle with a lack of knowledge and have limited resources, in particular MSEs and new companies.

Define “acceptable”

It was discussed what is found to be an acceptable level of impact. It is clear that seaweed cultivation will impact the environment, but the scale and severity of the impacts determine whether it is acceptable or not. In our view, this is rather a discussion to be held between policymakers and the local communities, which are the ones defining acceptability in the end. This could be captured by data collection from social scientists rather than only by marine biologists or ecologists. However, defining this acceptability early on, e.g., during step 1 familiarize (see Fig. 1), is important to ensure all stakeholders mean the same thing.

Identify best practices

Our research made clear that there is little accumulated experience with assessing the environmental hazards and how to mitigate them. This might partially be due to the green image seaweed cultivation has, reducing the urge to look at environmental hazards. Concerns on genetic aspects (e.g., ennoblement, the interaction between cultivation strains and natural populations) are perceived as urgent. Nowadays, a best practice approach is used, but what is defined as “best” differs strongly. For example, a participant in the workshop noted that while in northwest Europe, a region of ~100 km is used as the maximum distance between the cultivation site and the location where the parental material is derived from, Canada and the USA use ranges of respectively ~25 km and ~50 km.

Leverage supply chain pressure

Supply chain pressures on OHS can be used to a positive effect, especially when there is a longstanding, collaborative relationship between buyers and suppliers and there is some form of regulatory scrutiny and pressure (James et al. 2007). Buyers monitoring their suppliers’ arrangements in terms of food safety, environmental safety, and OHS could be an innovative approach in the relatively young seaweed sector in the West, with requirements by buyers being simple and consistent so that they do not put extra pressure on those companies that are new and/or small.

Using the generic protocol

The impact of the developed generic protocol relies upon the level of industry adoption, which will be shaped by a number of key assumptions and external factors, including the following:

-

Industry capacity and capability to adopt new monitoring best practices.

-

Availability of external project team resources (e.g., trained laboratory staff).

-

How generalizable are the protocols for other locations and production scales?

-

How clear and consistent safety monitoring requirements are for each specific seaweed value chain to allow farmers to improve arrangements (e.g., for OHS) and make informed choices on sampling design?

This study was focused on three disciplines — food safety, environmental safety, and OHS — but as the sector grows, new concerns might become more relevant, including, for instance, the dangers of seaweed farming infrastructure for other maritime infrastructures and transport. For example, the application of multi-use or co-location of seaweed with other foods (e.g., with mussel cultivation or fish farming) or non-food (e.g., at a windmill park) warrants attention. Furthermore, how these three disciplines are involved, as well as other disciplines (e.g., policy, structural engineers, other aquaculture farmers — mussel, fish, etc.), may also need to be considered in future evaluations of the generic protocol. Therefore, open access repositories with lessons learned after using and evaluating the generic protocol can support others in the seaweed sector with safety assessment and may help in lowering the time and resources needed for seaweed cultivation.

Conclusion

The experiences in the project confirmed that assessing the hazards, risks, and risk management of seaweed production and use for food is still in an early phase in Europe. There are no clear directions from buyers and limited experience from laboratories.

The Safe Seaweed by Design project tested and evaluated a prototype protocol for safe seaweed production and use in the food sector. Key lessons learned on the generic protocol include the following:

-

(i)

The protocol instigated a fruitful discussion on safety, providing a shared discourse to talk about safety.

-

(ii)

The protocol was successful in focusing data collection efforts on a number of key hazards considered most relevant in a practical setting (at offshore kelp farms in Norway), in particular for environmental and food safety.

-

(iii)

The production practices, the location, and the seaweed species can strongly influence which hazards are most relevant to environmental and food safety.

-

(iv)

The important role of regulators in setting the scene for risk management is apparent, as is regular communication on risk management between managers, scientists, and policymakers.

-

(v)

A facilitating approach that includes supply chain requirements and public bodies offering support when coming into contact with seaweed companies could contribute to improvements in all three aspects of food safety, environmental safety, and OHS.

The generic protocol was not developed to be a blueprint for risk management but to support a discussion on safety. Further development of the protocol is needed, in particular by applying it in specific settings, including those that extend beyond the cultivation of brown seaweed and especially where co-location or multi-use of seaweed is envisioned with other food systems. As experience builds up, it becomes easier to use these and make more efficient use of available background information and accumulated experience in dealing with seaweed safety.

Data Availability

Not applicable

Notes

Co-location is used when there is no interaction between different users, whereas multi-use does assume some interaction such as shared infrastructure or resources.

Originally, it was thought to use the criterion “available data.” After subsequent discussions, it became clear that the criterion “analytical feasibility” would be more useful for the continuation of the project. It was mentioned that missing data may well be a very good criterion to do further research on a hazard and should not be used as a reason for exclusion. In the final selection of the hazards, the data availability was still part of the discussion, yet here as a reason for inclusion to provide comparable data.

References

Araújo R, Calderón FV, López JS, Azevedo IC, Bruhn A, Fluch S, Tasende MG et al (2021) Current status of the algae production industry in Europe: an emerging sector of the blue bioeconomy. Frontiers in Marine Science 7. https://doi.org/10.3389/fmars.2020.626389

Asuelimen G, Blanco-Davis E, Wang J, Yang Z, Matellini DB (2020) Formal safety assessment of a marine seismic survey vessel operation, incorporating risk matrix and fault tree analysis. Journal of Marine Science and Application 19(2):155–172. https://doi.org/10.1007/s11804-020-00136-4

Banach JL, Hoek‐van den Hil EF, van der Fels‐Klerx HJ (2020) Food safety hazards in the European seaweed chain. Comprehensive Reviews in Food Science and Food Safety 1541-4337:12523. https://doi.org/10.1111/1541-4337.12523

Banach JL, Koch SJI, Hoffmans Y, van den Burg SWK (2022) Seaweed value chain stakeholder perspectives for food and environmental safety hazards. Foods 11(10):1514. https://doi.org/10.3390/foods11101514

Bello G, Jesus M (2018) Scientific prototyping: a novel approach to conduct research and engineer products. In: 2018 IEEE 9th International Conference on Software Engineering and Service Science (ICSESS), 32–35. IEEE. https://doi.org/10.1109/ICSESS.2018.8663862

Cai J, Lovatelli A, Aguilar-Manjarrez J, Cornish L, Dabbadie L, Desrochers A, Diffey S et al (2021) Seaweeds and microalgae: an overview for unlocking their potential in global aquaculture development. FAO. https://doi.org/10.4060/cb5670en

Camburn B, Viswanathan V, Linsey J, Anderson D, Jensen D, Crawford R, Otto K, Wood K (2017) Design prototyping methods: state of the art in strategies, techniques, and guidelines. Design Science 3:e13. https://doi.org/10.1017/dsj.2017.10

Campbell I, Macleod A, Sahlmann C, Neves L, Funderud J, Øverland M, Hughes AD, Stanley M (2019) The environmental risks associated with the development of seaweed farming in Europe - prioritizing key knowledge gaps. Frontiers in Marine Science 6. https://doi.org/10.3389/fmars.2019.00107

Cavalli L, Jeebhay MF, Marques F, Mitchell R, Neis B, Ngajilo D, Watterson A (2019) Scoping global aquaculture occupational safety and health. Journal of Agromedicine 24(4):391–404. https://doi.org/10.1080/1059924X.2019.1655203

Chung IK, Oak JH, Lee JA, Shin JA, Kim JG, Park K-s (2013) Installing kelp forests/seaweed beds for mitigation and adaptation against global warming: Korean project overview. Marine Science 70:1038–1044. https://doi.org/10.1093/icesjms/fss206

Dreyer, Marion, and Ortwin Renn. 2009. Risk , Governance And Society.

Duarte CM, Bruhn A, Krause-Jensen D (2021) A seaweed aquaculture imperative to meet global sustainability targets. Nature Sustainability. https://doi.org/10.1038/s41893-021-00773-9

EU-OSHA. (2018) Safety and health in micro and small enterprises in the EU: final report from the 3-year SESAME project, Luxembourg

FAO and WHO (2022) Report of the expert meeting on food safety for seaweed – current status and future perspectives. FAO; WHO, Rome. https://doi.org/10.4060/cc0846en

Frewer L (2000) Risk perception and risk communication about food safety issues. Nutrition Bulletin 25(1):31–33. https://doi.org/10.1046/j.1467-3010.2000.00015.x

Froehlich HE, Afflerbach JC, Frazier M, Halpern BS (2019) Blue growth potential to mitigate climate change through seaweed offsetting. Current Biology : CB 29(18):3087–3093.e3. https://doi.org/10.1016/j.cub.2019.07.041

Fry JP, Ceryes CA, Voorhees JM, Barnes NA, Love DC, Barnes ME (2019) Occupational safety and health in U.S. aquaculture: a review. Journal of Agromedicine. Taylor and Francis Ltd. https://doi.org/10.1080/1059924X.2019.1639574

Glette-Iversen I, Aven T, Flage R (2022) The concept of plausibility in a risk analysis context: review and clarifications of defining ideas and interpretations. Safety Science 147:105635. https://doi.org/10.1016/j.ssci.2021.105635

Groth, Markus, and Peer Seipold. 2020. “Business strategies and climate change—prototype development and testing of a user specific climate service product for companies.” , 51–66. https://doi.org/10.1007/978-3-030-36875-3_4.

Gurgis JJ, Kerr G, Battaglia A (2022) Exploring stakeholders’ interpretations of safe sport. Journal of Sport and Social Issues. https://doi.org/10.1177/01937235221134610

Hasselström L, Thomas J-B, Nordström J, Cervin G, Nylund GM, Pavia H, Gröndahl F (2020) Socioeconomic prospects of a seaweed bioeconomy in Sweden. Scientific Reports 10(1):1610. https://doi.org/10.1038/s41598-020-58389-6

Holen, Siri M, Ingrid Bouwer Utne, Marie Holmen, and Halvard Aasjord. n.d. “Occupational safety in aquaculture-part 1: injuries in Norway.”

Indrayani NL, Dwi J-JW, Chang J-H, Permatasari H, Wang C-J (2022) Development of an educational protocol for ergonomic risk assessment of working postures to enhance the competence of occupational health nurses. International Journal of Nursing Practice 28(5). https://doi.org/10.1111/ijn.13052

James P, Johnstone R, Quinlan M, Walters D (2007) Regulating supply chains to improve health and safety. Industrial Law Journal 36(2):163–187. https://doi.org/10.1093/indlaw/dwm002

Jiang Z, Liu J, Li S, Chen Y, Ping D, Zhu Y, Liao Y et al (2020) Kelp cultivation effectively improves water quality and regulates phytoplankton community in a turbid, highly eutrophic bay. Science of the Total Environment 707:135561. https://doi.org/10.1016/j.scitotenv.2019.135561

Kirk B, Thompson S (2021) Identifying local oil spill risk factors: an application of hazard identification within the international maritime organization formal safety assessment framework in Washington State. International Oil Spill Conference Proceedings 2021(1). https://doi.org/10.7901/2169-3358-2021.1.677002

Knapp S, Franses PH (2010) Comprehensive review of the maritime safety regimes: present status and recommendations for improvements. Transport Reviews 30(2):241–270. https://doi.org/10.1080/01441640902985934

Kuech A, Breuer M, Popescu I (2023) Research for PECH Committee – the future of the EU algae sector, Brussels

Lee J, Chae K-J (2021) A systematic protocol of microplastics analysis from their identification to quantification in water environment: a comprehensive review. Journal of Hazardous Materials 403:124049. https://doi.org/10.1016/j.jhazmat.2020.124049

Legg SJ, Olsen KB, Laird IS, Hasle P (2015) Managing safety in small and medium enterprises. Safety Science 71:189–196. https://doi.org/10.1016/j.ssci.2014.11.007

Lozano Muñoz I, Díaz NF (2022) Minerals in edible seaweed: health benefits and food safety issues. Critical Reviews in Food Science and Nutrition 62(6):1592–1607. https://doi.org/10.1080/10408398.2020.1844637

Marshall TM (2020) Risk perception and safety culture: tools for improving the implementation of disaster risk reduction strategies. International Journal of Disaster Risk Reduction 47:101557. https://doi.org/10.1016/j.ijdrr.2020.101557

Mateo JP, Campbell I, Cottier-Cook EJ, Luhan MRJ, Ferriols VMEN, Hurtado AQ (2020) Analysis of biosecurity-related policies governing the seaweed industry of the Philippines. Journal of Applied Phycology 32(3):2009–2022. https://doi.org/10.1007/s10811-020-02083-7

Monaghan JM, Augustin JC, Bassett J, Betts R, Pourkomailian B, Zwietering MH (2017) Risk assessment or assessment of risk? Developing an evidence-based approach for primary producers of leafy vegetables to assess and manage microbial risks. Journal of Food Protection 80(5):725–733. https://doi.org/10.4315/0362-028X.JFP-16-237

Nawrot J, Pepłowska-Dąbrowska Z (2020) Maritime safety in Europe. In: Nawrot J, Pepłowska-Dąbrowska Z (eds) Informa Law from Routledge. https://doi.org/10.4324/9781003030775

Nayak R, Waterson P (2019) Global food safety as a complex adaptive system: key concepts and future prospects. Trends in Food Science & Technology 91:409–425. https://doi.org/10.1016/j.tifs.2019.07.040

Quinlan M, Mayhew C, Bohle P (2001) The global expansion of precarious employment, work disorganization, and consequences for occupational health: a review of recent research. International Journal of Health Services. https://doi.org/10.2190/607H-TTV0-QCN6-YLT4

Quinlan M, Bohle P (2009) Overstretched and unreciprocated commitment: reviewing research on the occupational health and safety effects of downsizing and job insecurity. International Journal of Health Services. https://doi.org/10.2190/HS.39.1.a

Racine P, Marley AC, Froehlich HE, Gaines SD, Ladner I, MacAdam-Somer I, Bradley D (2021) A case for seaweed aquaculture inclusion in U.S. nutrient pollution management. Marine Policy 129:104506. https://doi.org/10.1016/j.marpol.2021.104506

Radulovich R, Umanzor S, Cabrera R, Mata R (2015) Tropical seaweeds for human food, their cultivation and its effect on biodiversity enrichment. Aquaculture 436:40–46. https://doi.org/10.1016/j.aquaculture.2014.10.032

Rebours C, Marinho-Soriano E, Zertuche-González JA, Hayashi L, Vásquez JA, Kradolfer P, Soriano G et al (2014) Seaweeds: an opportunity for wealth and sustainable livelihood for coastal communities. Journal of Applied Phycology 26(5):1939–1951. https://doi.org/10.1007/s10811-014-0304-8

Renn O, Klinke A (2015) Risk governance and resilience: new approaches to cope with uncertainty and ambiguity. In: Paleo UF (ed) Risk Governance: The Articulation of Hazard, Politics and Ecology. Springer Netherlands, Dordrecht, pp 19–41. https://doi.org/10.1007/978-94-017-9328-5_2

Sá Monteiro M, Sloth J, Holdt S, Hansen M (2019) Analysis and risk assessment of seaweed. EFSA Journal 17. https://doi.org/10.2903/j.efsa.2019.e170915

Schreier VN, Appenzeller-Herzog C, Brüschweiler BJ, Geueke B, Wilks MF, Simat TJ, Schilter B et al (2022) Evaluating the food safety and risk assessment evidence-base of polyethylene terephthalate oligomers: protocol for a systematic evidence map. Environment International 167:107387. https://doi.org/10.1016/j.envint.2022.107387

Shannon E, Abu-Ghannam N (2019) Seaweeds as nutraceuticals for health and nutrition. Phycologia 58(5):563–577. https://doi.org/10.1080/00318884.2019.1640533

Tonk L, Jansen HM, Poelman M, Nauta RW, Jak RG, Tamis JE, Jongbloed RH (2021) Development of a framework and toolbox for measuring and evaluating ecosystem interactions of seaweed aquaculture. https://doi.org/10.18174/553741

Van Asselt MB, Renn O (2011) Risk governance. Journal of Risk Research 14(4):431–449. https://doi.org/10.1080/13669877.2011.553730

Van den Burg SW, Röckmann C, Banach JL, Van Hoof L (2020) Governing risks of multi-use: seaweed aquaculture at offshore wind farms. Frontiers in Marine Science https://www.frontiersin.org/article/10.3389/fmars.2020.00060

Van der Meer J (2020) Limits to food production from the sea. Nature Food 1(12):762–764. https://doi.org/10.1038/s43016-020-00202-8

van der Spiegel M, Noordam MY, van der Fels-Klerx HJ (2013) Safety of novel protein sources (insects, microalgae, seaweed, duckweed, and rapeseed) and legislative aspects for their application in food and feed production. Comprehensive Reviews in Food Science and Food Safety 12(6):662–678. https://doi.org/10.1111/1541-4337.12032

van Hoof L, van den Burg SWK, Banach JL, Röckmann C, Goossen M (2020) Can multi-use of the sea be safe? A framework for risk assessment of multi-use at sea. Ocean & Coastal Management 184:105030. https://doi.org/10.1016/j.ocecoaman.2019.105030

van Wassenhove W, Foussard C, Dekker SWA, Provan DJ (2022) A qualitative survey of factors shaping the role of a safety professional. Safety Science 154:105835. https://doi.org/10.1016/j.ssci.2022.105835

Vazquez Calderon F, Sanchez Lopez J (2022) An overview of the algae industry in Europe, Luxembourg

Venable, John, Jan Pries-Heje, and Richard Baskerville. 2012. “A comprehensive framework for evaluation in design science research.” , 423–38. https://doi.org/10.1007/978-3-642-29863-9_31.

Walters D, James P (2011) What motivates employers to establish preventive management arrangements within supply chains? Safety Science 49(7):988–994. https://doi.org/10.1016/j.ssci.2010.12.004

Watterson A, Jeebhay M, Neis B, Mitchell R, Cavalli L (2019) The neglected millions: the global state of aquaculture workers’ occupational safety, health and well-being. Occup Environ Med 77(1):15–18

Wilding, C. Tillin. 2021. Seaweed aquaculture and mechanical harvesting : an evidence review to support sustainable management.

Wood D, Capuzzo E, Kirby D, Mooney-McAuley K, Kerrison P (2017) UK macroalgae aquaculture: what are the key environmental and licensing considerations? Marine Policy 83:29–39. https://doi.org/10.1016/j.marpol.2017.05.021

Xiao X, Agusti S, Lin F, Li K, Pan Y, Yan Y, Zheng Y, Jiaping W, Duarte CM (2017) Nutrient removal from Chinese coastal waters by large-scale seaweed aquaculture. Scientific Reports 7(1):46613. https://doi.org/10.1038/srep46613

Yong WT, Lym VY, Thien RR, Rodrigues KF (2022) Seaweed: a potential climate change solution. Renewable and Sustainable Energy Reviews 159:112222. https://doi.org/10.1016/j.rser.2022.112222

Acknowledgements

We thank the respondents and participants in the workshop for their valuable insights. Thanks go out to the Safe Seaweed by Design colleagues who did not co-author this paper, including Jon Barlow, Rebekah Simmons, Emma Termeer, Marion Bogers, Els Faassen, Rosa Safitri, and David Cohen and to the students Marjoleine Hoefsloot, Daan ten Berge, and Wouter Boerjan who contributed to the project.

Code availability

Not applicable

Funding

Safe Seaweed by Design was commissioned and financed by the Lloyds Register Foundation under grant reference GA\100395. For more information about the project, see https://www.wur.nl/en/project/Safe-Seaweed-by-Design.htm.

Author information

Authors and Affiliations

Contributions

All authors whose names appear on the submission made substantial contributions to the conception or design of the work or the acquisition, analysis, or interpretation of data. All authors are involved in drafting the paper or revising it critically for important intellectual content. All authors approved the version to be published and agreed to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Competing interests

S. Post and K. Kristensen are employed by or own Arctic Seaweed AS. Both have been consulted in the study and participated in the pilot.

Additional information

Handling Editor: Ronan Sulpice

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

van den Burg, S.W.K., Koch, S.J.I., Banach, J.L. et al. Learning to discuss safety within the European seaweed aquaculture sector. Aquacult Int 32, 3935–3956 (2024). https://doi.org/10.1007/s10499-023-01358-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10499-023-01358-3