Abstract

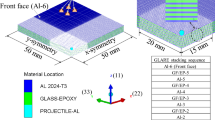

The ion thruster is an engine with high specific impulse for satellites and spacecrafts, which uses electric energy to boost the spacecraft. The ion optical system, also known as gate assemblies which consist of acceleration and screen grids, is the key component of the ion thruster. In this paper, the static mechanical properties of the C/C composite grids are evaluated based on the structural design. Representative volume element (RVE) is adopted to simplify the braded composite structure as a continuum material. The dynamical behavior of the 100mm ion thruster optics in the launch environment (1 000g shock-load) is numerically modeled and simulated with the half-sine pulse method. The impact response of the C/C and molybdenum gate assemblies on the stress distribution and deformation is investigated. The simulated results indicate that the magnitudes of the normal displacement of the composite grids subject to the uniformly distributed load are on the same level as molybdenum grids although the normal stiffness of the composite grids is much smaller. When subject to impact loading, the stress distribution in the C/C composite grids is similar to molybdenum grids while the stress magnitude is much smaller. This finding shows that the C/C gate assemblies outperform molybdenum grids and meet the requirement of long lifetime service in space travel.

Similar content being viewed by others

References

KILLINGER, R., KUKIES, R., SURAUER, M., TOMASETTO, A., and VAN HOLTZ, L. Artemis orbit raising inflight experience with ion propulsion. Acta Astronautica, 53(4–10), 607–621 (2003)

BROPHY, J. Advanced ion propulsion systems for affordable deep-space missions. Acta Astronautica, 52(2), 309–316 (2000)

RAYMAN, M. D., FRASCHETTI, T. C., RAYMOND, C. A., and RUSSEL, C. T. Coupling of system resource margins through the use of electric propulsion: implications in preparing for the Dawn mission to Ceres and Vesta. Acta Astronautica, 60(10–11), 930–938 (2007)

WANG, J., POLK, J., BROPHY, J., and KATZ, I. Three-dimensional particle simulations of ion-optics plasma flow and grid erosion. Journal of Propulsion and Power, 19(6), 1192–1199 (2015)

JIAN, H. H., CHU, Y. C., CAO, H. J., CAO, Y., HE, X. M., and XIA, G. Q. Three-dimensional IFE-PIC numerical simulation of background pressure’s effect on accelerator grid impingement current for ion optics. Vacuum, 116(8), 130–138 (2015)

FARNELL, C. C. Performance and lifetime simulation of ion thruster optics. Colorado State School, 20-21, 49–66 (2007)

POLK, J. E., MOORE, N. R., BROPHY, J. R., NEWLIN, L. E., and EBBELER, D. H. Probabilistic Analysis of Ion Engine Accelerator Grid Life, NASA Technical Report, 20060039386, NASA (1993)

DAN, M. G. and KATZ, I. Fundamentals of electric propulsion: ion and hall thrusters. JPL Space Science and Technology Series, John Wiley & Sons, Inc., California, 216–235 (2008)

MUELLER, J., BROPHY, J. R., BROWN, D. K., and GARNER, C. E. Performance characteristics of 15 cm carbon-carbon composite grids. Joint Propulsion Conference and Exhibit, American Institute of Aeronautics and Astronautics, Reston (1994)

MUELLER, J., BROPHY, J., and BROWN, D. Endurance testing and fabrication of advanced 15 cm and 30 cm carbon-carbon composite grids. 31st Joint Propulsion Conference and Exhibit, American Institute of Aeronautics and Astronautics, Reston (2013)

MUELLER, J., BROPHY, J. R., and BROWN, D. K. Design, fabrication, and testing of 30 cm dia dished carbon-carbon ion engine grids. 32nd Joint Propulsion Conference and Exhibit, American Institute of Aeronautics and Astronautics, Reston (1996)

BEATTY, J., SNYDER, J., and WEI, S. Manufacturing of 57 cm carbon composite ion optics for a 20-kW-class ion engine. 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, American Institute of Aeronautics and Astronautics, Reston (2005)

CHENG, L. F., ZHANG, L. T., MEI, H., LIU, Y. S., and ZENG, Q. F. Manufacturing of CMCs by chemical vapor infiltration process (in Chinese). Journal of Shanghai University (Natural Science), 20(1), 15–32 (2014)

FENG, Z. H., FAN, Z., KONG, Q., YU, L. Q., and Xu, L. Preparation of high thermal conductivity C/C composite (in Chinese). Journal of Shanghai University (Natural Science), 20(1), 51–58 (2014)

FANG, J. M., XU, Z. H., ZHANG, Z. W., LI, A. J., and TANG, Z. P. Multi-scale relationship of pores in carbon cloth stitched preform and deposition of pyrocarbon. Aerospace Materials and Technology, 45(5), 36–39 (2015)

ZHANG, D., AROLA, D., CHARALAMBIDES, P. G., and PATTERSON, M. C. L. On the mechanical behavior of carbon-carbon optic grids determined using a bi-axial optical extensometer. Journal of Materials Science, 39(14), 4495–4505 (2004)

YAN, X., XU, X. W., and Zhang, C. Analysis of elastic properties of 2D triaxial braided composites. Chinese Journal of Solid Mechanics, 34(2), 140–151 (2013)

YANG, M., SUN, J. L., REN, M. S., LI, H., and BAI, R. C. Nanohardness and elastic modulus of pyrocarbon. Journal of Shanghai University (Natural Science), 14(5), 541–545 (2008)

TSAI, K. H., HWAN, C. L., CHEN, W. L., and CHIU, C. H. A parallelogram spring model for predicting the effective elastic properties of 2D braided composites. Composite Structures, 83(3), 273–283 (2008)

MA, H., XIA, L. W., and QIN, Q. H. Computational model for short-fiber composite with eigenstrain formulation of boundary integral equations. Applied Mathematics and Mechanics (English Edition), 29(6), 757–767 (2008) https://doi.org/10.1007/s10483-008-0607-4

EBRAHIMI, F. and BARATI, M. R. Dynamic modeling of preloaded size-dependent nano-crystalline nano-structures. Applied Mathematics and Mechanics (English Edition), 38(12), 1753–1772 (2017) https://doi.org/10.1007/s10483-017-2291-8

KITAMURA, S., HAYAKAWA, Y., KASAI, Y, and QZAKI, T. Fabrication of Carbon-Carbon Composite Ion Thruster Grids Improvement of Structural Strength, IEPC 97-093 (1997)

YANG, W., GAO, Q., and LU, F. L. Implementation of buffer design for equipments on aircraft. Structure and Environment Engineering, 41(1), 37–44 (2014)

MANABE, T., KONDO, H., and KISHI, H. Rubber reinforcing cord and fiber reinforced rubber material: US, US6835447 (2004)

ALY-HASSAN, M. S., HATTA, H., WAKAYAMA, S., WATANABE, M., and MIYAGAWA, K. Comparison of 2D and 3D carbon/carbon composites with respect to damage and fracture resistance. Carbon, 41(5), 1069–1078 (2003)

LU, Z. X., HUANG, J. X., and YUAN, Z. S. Effects of microstructure on uniaxial strength asymmetry of open-cell foams. Applied Mathematics and Mechanics (English Edition), 36(1), 37–46 (2015) https://doi.org/10.1007/s10483-015-1893-9

HATTA, H., GOTO, K., and IKEGAKI, S. Tensile strength and fiber/matrix interfacial properties of 2D- and 3D-carbon/carbon composites. Journal of the European Ceramic Society, 25(4), 535–542 (2005)

Author information

Authors and Affiliations

Corresponding author

Additional information

Citation: ZHANG, S. Q., LI, A. J., ZHENG, Y. Q., and ZHANG, D. S. Mechanical analysis of C/C composite grids in ion optical system. Applied Mathematics and Mechanics (English Edition), 40(11), 1589–1600 (2019) https://doi.org/10.1007/s10483-019-2527-9

Project supported by the National Key R&D Program of China (No. 2018YFF01014200) and the National Natural Science Foundation of China (Nos. 11727804, 11672347, and 51732008)

Rights and permissions

About this article

Cite this article

Zhang, S., Li, A., Zheng, Y. et al. Mechanical analysis of C/C composite grids in ion optical system. Appl. Math. Mech.-Engl. Ed. 40, 1589–1600 (2019). https://doi.org/10.1007/s10483-019-2527-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-019-2527-9