Abstract

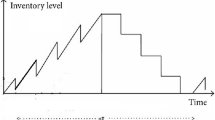

This paper addresses a scheduling problem in a flexible supply chain, in which the jobs can be either processed in house, or outsourced to a third-party supplier. The goal is to minimize the sum of holding and delivery costs. This problem is proved to be strongly \(\mathcal{NP}\)-hard. Consider two special cases, in which the jobs have identical processing times. For the problem with limited outsourcing budgets, a \(\mathcal{NP}\)-hardness proof, a pseudo-polynomial algorithm and a fully polynomial time approximation scheme are presented. For the problem with unlimited outsourcing budgets, the problem is shown to be equivalent to the shortest path problem, and therefore it is in class \(\mathcal{P}\). This shortest-path-problem solution approach is further shown to be applicable to a similar but more applicable problem, in which the number of deliveries is upper bounded.

Similar content being viewed by others

References

Agnetis, A., Hall, N. G., & Pacciarelli, D. (2006). Supply chain scheduling: sequence coordination. Discrete Applied Mathematics, 154(15), 2044–2063.

Chen, Z.-L. (2010). Integrated production and outbound distribution scheduling: review and extensions. Operations Research, 58(1), 130–148.

Chen, Z.-L., & Hall, N. G. (2007). Supply chain scheduling: conflict and cooperation in assembly systems. Operations Research, 55, 1072–1089.

Chen, Z.-L., & Vairaktarakis, G. L. (2005). Integrated scheduling of production and distribution operations. Management Science, 51, 614–628.

Cheng, G., & Ansari, N. (2003). A new heuristics for finding the delay constrained least cost path. IEEE Global Telecommunications Conference (GLOBECOM’03), 2003(7), 3711–3715.

Engels, D. W., Karger, D. R., Kolliopoulos, S. G., Sengupta, S., Uma, R. N., & Wein, J. (2003). Techniques for scheduling with rejection. Journal of Algorithms, 49(1), 175–191.

Garey, M. R., & Johnson, D. S. (1979). Computers and intractability: a guide to the theory of NP-completeness. New York: Freeman. 1979.

Graham, R. L., Lawler, E. L., Lenstra, J. K., & Rinnooy Kan, A. H. G. (1979). Optimization and approximation in deterministic sequencing and scheduling: a survey. Annals of Discrete Mathematics, 4, 287–326.

Hall, N. G., & Potts, C. N. (2003). Supply chain scheduling, batching and delivery. Operations Research, 51(4), 566–584.

Hassin, R. (1992). Approximation schemes for the restricted shortest path problem. Mathematics of Operations Research, 17(1), 36–42.

Lawler, E. L. (1982). A fully polynomial time approximation scheme for the total tardiness problem. Operations Research Letters, 1(6), 207–208.

McKenna Long & Aldridge LLP (2004). Recent budget provision limits offshoring of jobs under outsourced federal contracts: legislation introduced. In Several states related to state procurements. www.mckennalong.com.

Qi, X. T. (2008). Coordinated logistics scheduling for in-house production and outsourcing. IEEE Transactions on Automation Science and Engineering, 5(1), 188–192.

Selvarajah, E., & Steiner, G. (2009). Approximation algorithms for the supplier’s supply chain scheduling problem to minimize delivery and inventory holding costs. Operations Research, 57(2), 426–438.

Selvarajah, E., Steiner, G., & Zhang, R. (2011). Single machine batch scheduling with release times and delivery costs. Journal of Scheduling. Online FirstTM. doi:10.1007/s10951-011-0255-8.

Shabtay, D., Gaspar, N., & Kaspi, M. (2013). A survey on offline scheduling with rejection. Journal of Scheduling, 16, 2–282.

Shabtay, D., & Steiner, G. (2007). A survey of scheduling with controllable processing times. Discrete Applied Mathematics, 155(13), 1643–1666.

Smith, W. E. (1956). Various optimizers for single-stage production. Naval Research Logistics Quarterly, 3, 59–66.

Steiner, G., & Zhang, R. (2011). Revised delivery-time quotation in scheduling with tardiness penalties. Operations Research, 59(6), 1504–1511.

Thomas, D. J., & Griffin, P. M. (1996). Coordinated supply chain management. European Journal of Operational Research, 94, 1–15.

Wang, X. L., & Cheng, T. C. E. (2009). Production scheduling with supply and delivery considerations to minimize the makespan. European Journal of Operational Research, 194(3), 743–752.

Zhang, L. Q., Lu, L. F., & Yuan, J. J. (2010). Single-machine scheduling under the job rejection constraint. Theoretical Computer Science, 411(16–18), 1877–1882.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was supported in part by NSERC Discovery Grant 1798-03.

Rights and permissions

About this article

Cite this article

Selvarajah, E., Zhang, R. Supply chain scheduling to minimize holding costs with outsourcing. Ann Oper Res 217, 479–490 (2014). https://doi.org/10.1007/s10479-013-1522-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-013-1522-1