Abstract

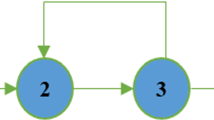

A multipurpose/multiproduct plant has to deal with many combinations of tasks sequences and operation rates that lead to accumulation problems. These problems can be handled using storage tanks, but usually their location within the flowsheet is predetermined and not subject to optimization, missing the opportunity to better satisfy the customers. In this work we will determinate the optimal location of storage tanks for the short-term scheduling under uncertainty. A hybrid simulation-based optimization (SBO) strategy was developed and implemented to solve the problems combining stochastic and deterministic solution algorithms.

Similar content being viewed by others

References

Adonyi, R., Biros, G., Holczinger, T., & Friedler, F. (2008). Effective scheduling of a large-scale paint production system. Journal of Cleaner Production, 16, 225–232.

Aydogan, S., Orçun, S., Blau, G., Pekny, J. F., & Reklaitis, G. V. (2005). A simulation-based optimization approach to the evolution of an advanced life support system for Mars base. In Proceedings of 2005 AIChE annual meeting, Cincinnati (EEUU), 10/30/05–11/04/05, oral presentation code 104f.

Balasubramanian, J., & Grossmann, I. E. (2004). Approximation to multistage stochastic optimization in multiperiod batch plant scheduling under demand uncertainty. Industrial & Engineering Chemistry Research, 43, 3695–3713.

Barton, R. R. (1994). Metamodeling: a state of the art review. In J. D. Tew, S. Manivannan, D. A. Sadowski, & A. F. Seila (Eds.), Proceedings of the 1994 winter simulation conference (p. 237).

Birge, Z., & Louveaux, S. (1997). Principles on stochastic programming. New York: Springer.

Brooke, A., Kendrick, D., Meeraus, A., & Raman, R. (2008). GAMS: a user guide. Washington: GAMS Development Corporation.

Castro, P. M., Barbosa-Póvoa, A. P., Matos, H. A., & Novais, A. Q. (2004). Simple continuous-time formulation for short-term scheduling of batch and continuous processes. Industrial & Engineering Chemistry Research, 43, 105–118.

Cheng, L., Subrahmanian, E., & Westerberg, A. W. (2003). Design and planning under uncertainty: issues on problem formulations and solutions. Computers & Chemical Engineering, 27, 781–801.

Cheng, L., Subrahmanian, E., & Westerberg, A. W. (2004a). A comparison of optimal control and stochastic programming from a formulation and computation perspective. Computers & Chemical Engineering, 29, 149–164.

Cheng, L., Subrahmanian, E., & Westerberg, A. W. (2004b). Multiobjective decisions on capacity planning and inventory control. Industrial & Engineering Chemistry Research, 43, 2192–2208.

Diwekar, U. (2002). Optimization under uncertainty: an overview. SIAG/Optimization Views-and-News, 13(1), 1–8.

Duenas, A., & Petrovic, D. (2000). An approach to predictive-reactive scheduling of parallel machines subject to disruptions. Annals of Operations Research, 159(1), 65–82.

Ferris, M. C., Dirkse, S., & Jain, R. (2005). MATLAB and GAMS: interfacing optimization and visualization software. Computer Sciences Department, University of Wisconsin at Madison, Madison. http://www.cs.wisc.edu/math-prog/matlab.html. Accessed October 7, 2010.

George, E. D., & Farid, S. S. (2008). Stochastic combinatorial optimization approach to biopharmaceutical portfolio management. Industrial & Engineering Chemistry Research, 47, 8762–8774.

Gosavi, A. (2003). Simulation-based optimization: parametric optimization techniques and reinforcement learning. New York: Springer. ISBN-10: 1402074549, ISBN-13: 978-1402074547.

Gürkan, G. (2000). Simulation optimization of buffer allocations in production lines with unreliable machines. Annals of Operations Research, 93, 177–216.

Ierapetritou, M. G., & Floudas, C. A. (1998). Effective continuous-time formulation for short-term scheduling: II. Continuous and semi-continuous processes. Industrial & Engineering Chemistry Research, 37, 4360–4374.

International Society for Measurement and Control (1995). ANSI/ISA-S88.01-1995, Batch Control, Part 1: Models and Terminology, 23/10/1995.

International Society for Measurement and Control (2000). ISA-S95.01-1999, Enterprise Control System Integration, Part 1: Models and Terminology. Draft 13.

Jung, J. Y., Blau, G., Pekny, J. F., Reklaitis, G. V., & Eversdyk, D. (2004). A simulation based optimization approach to supply chain management under demand uncertainty. Computers & Chemical Engineering, 28, 2087–2106.

Kim, M., Rao, A. S., & Yoo, C. (2009). Dual optimization strategy for N and P removal in a biological wastewater treatment plant. Industrial & Engineering Chemistry Research, 48, 6363–6371.

Kleinman, N. L., Spall, J. C., & Naiman, D. Q. (1999). Simulation-based optimization with stochastic approximation using common random numbers. Management Science, 45, 1570.

Kuster, J., Jannach, D., & Friedrich, G. (2010). Applying local rescheduling in response to schedule disruptions. Annals of Operations Research, 180(1), 265–282.

Law, A. M., & Kelton, W. D. (2000). Simulation modeling & analysis (3rd edn.). New York: McGraw-Hill.

MATLAB 7.5 (2007). Simulink 6.0, Stateflow 6.0. User’s manual. Natick: The MathWorks, Inc.

Mele, F. D., Espuña, A., & Puigjaner, L. (2006a). Supply chain management through dynamic model parameters optimization. Industrial & Engineering Chemistry Research, 45, 1708–1721.

Mele, F. D., Guillén, G., Espuña, A., & Puigjaner, L. (2006b). A simulation-based optimization framework for parameter optimization of supply-chain networks. Industrial & Engineering Chemistry Research, 45, 3133–3148.

Nedderrneijer, H. G., van Oortmarssen, G. J., Piersma, N., & Dekker, R. (2000). A framework for response surface methodology for simulation optimization. In Proceedings of the 1999 winter simulation conference.

Shaik, M. A., & Floudas, C. A. (2009). Novel unified modeling approach for short-term scheduling. Industrial & Engineering Chemistry Research, 48, 2947–2964.

Silva, H. G., & Salcedo, R. L. R. (2009). A coupled strategy for the solution of NLP and MINLP optimization problems—benefits and pitfalls. Industrial & Engineering Chemistry Research, 48, 9611–9621.

Subramanian, D., Pekny, J. F., & Reklaitis, G. V. (2001). A simulation-optimization framework for research and development pipeline management. AIChE Journal, 47, 2226–2242.

Subramanian, D., Pekny, J. F., Reklaitis, G. V., & Blau, G. E. (2003). A simulation-optimization framework for stochastic optimization of R&D pipeline management. AIChE Journal, 49, 96–112.

Sundaramoorthy, A., & Maravelias, C. T. (2008). Modeling of storage in batching and scheduling of multistage processes. Industrial & Engineering Chemistry Research, 47, 6648–6660.

Sundar Raj, T., & Lakshminarayanan, S. (2008). Multiobjective optimization in multiechelon decentralized supply chains. Industrial & Engineering Chemistry Research, 47, 6661–6671.

Wan, X., Pekny, J. F., & Reklaitis, G. V. (2005). Simulation-based optimization with surrogate models—application to supply chain management. Computers & Chemical Engineering, 29, 1317–1328.

Author information

Authors and Affiliations

Corresponding author

Additional information

An outline of this work was first presented in the ALIO-INFORMS Joint International Conference 2010, Buenos Aires.

Rights and permissions

About this article

Cite this article

Durand, G.A., Mele, F.D. & Bandoni, J.A. Determination of storage tanks location for optimal short-term scheduling in multipurpose/multiproduct batch-continuous plants under uncertainties. Ann Oper Res 199, 225–247 (2012). https://doi.org/10.1007/s10479-011-0970-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-011-0970-8