Abstract

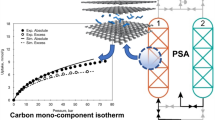

A three-step design methodology was developed for applying ideal cascade theory to separate a dilute binary gas mixture by pressure swing adsorption (PSA). This methodology was tested via simulation and applied to the enrichment of 14CO from 1 to 20 ppm in a mixture of its own isotopes. It was assumed that the presence and slight enrichment of 13CO did not affect the performance of 14CO throughout the cascade. An 8 stage cascade was analyzed, with 3 stages in the stripping section, 5 stages in the enriching section and the feed fed to stage 4. Each stage consisted of a 3-bed 3-step PSA process of varying size, all utilizing feed pressurization/feed, heavy reflux and countercurrent depressurization steps of equal duration, and the same total cycle time. The performance in terms of overall 14CO recovery from an ideal cascade of PSA units was compared to that from a single PSA unit operating with the same overall 14CO enrichment and same overall throughput as the cascade. The results showed that the cascade of PSA units compared to the single PSA unit exhibited increasingly higher overall recoveries as the overall enrichment decreased; the performance of both systems became identical at an overall enrichment of about 18; and at overall enrichments higher than 18 the single PSA unit exhibited only slightly higher overall recoveries than the cascade of PSA units. The better performing separation process in either case always required more power to operate. In general, this analysis showed how to design an ideal cascade of PSA units for binary isotope separation and that a cascade of PSA units may be more advantageous than a single PSA unit, depending on the desired performance and as long as the capital and operating costs are acceptable.

Similar content being viewed by others

Abbreviations

- D i :

-

Depletion of species of interest at stage i

- E i :

-

Enrichment of species of interest at stage i

- F :

-

Primary feed flow of the PSA cascade

- F i :

-

Feed flow to stage i

- HP i :

-

Heavy product flow at stage i

- I :

-

Stage i

- L i :

-

Tail flow in the depleted stream at stage i or loss of species of interest at stage i

- LP i :

-

Light product flow at stage i

- M :

-

Total number of stages in stripping section

- N :

-

Total number of stages in enriching section

- N :

-

Total number of moles exiting the bed during the CnD step

- n i :

-

Total number of moles exiting the bed during the CnD step at stage i

- N T :

-

Total number of stages in the cascade

- P :

-

Head or enriched product flow from the PSA cascade

- P i :

-

Head or enriched product flow from stage i

- P i−1 :

-

Head or enriched product flow from stage i − 1

- R i :

-

Recovery of species of interest at stage i

- R R :

-

Heavy product reflux ratio

- R R,i :

-

Heavy product reflux ratio at stage i

- t step :

-

Duration of production step

- v :

-

Volume of each PSA bed

- v i :

-

Volume of PSA bed at stage i

- V i :

-

Head flow in the enriched stream at stage i

- W :

-

Tail or lean product flow from PSA cascade

- W i :

-

Tail or lean product flow from stage i

- W i+1 :

-

Tail or lean product flow from stage i + 1

- x i :

-

Depleted stream composition of strongly adsorbed species at stage i

- x i+1 :

-

Depleted stream composition of strongly adsorbed species at stage i + 1

- x i+2 :

-

Depleted stream composition of strongly adsorbed species at stage i + 2

- X i :

-

Molar ratio of strongly adsorbed species of depleted stream at stage i

- xw :

-

Depleted product composition of strongly adsorbed species

- y i :

-

Enriched stream composition of strongly adsorbed species at stage i

- y i−1 :

-

Enriched stream composition of strongly adsorbed species at stage i − 1

- y i−2 :

-

Enriched stream composition of strongly adsorbed species at stage i − 2

- Y i :

-

Molar ratio of strongly adsorbed species of enriched stream at stage i

- y P or y p :

-

Enriched product composition of strongly adsorbed species

- z i :

-

Feed composition of strongly adsorbed species at stage i

- z i+1 :

-

Feed composition of strongly adsorbed species at stage i + 1

- z i−1 :

-

Feed composition of strongly adsorbed species at stage i − 1

- Z i :

-

Molar ratio of strongly adsorbed species of feed stream at stage i

- z F or z f :

-

Primary feed composition of strongly adsorbed species

- ρ b :

-

Bulk density of the bed

- α i :

-

Separation factor of stage i

- β :

-

Head or tail separation factor

- β 1,i :

-

Head separation factor

- β 2,i :

-

Tail separation factor

- θ :

-

Constant stage throughput (θ i = θ = constant)

- θ i :

-

Stage throughput

- θ overall :

-

Overall throughput (cascade or single PSA unit)

- ψ :

-

Total number of moles exiting the bed during the CnD step per volume of bed

References

Ambartsumian, R.V., Letokhov, V.S., Ryabov, E.A., Chekalin, N.V.: (1975) Isotopic selective chemical reaction of BCl3 molecules in a strong infrared laser field. ZhETF Pisma Redaktsiiu. 20, 597 (1974)

Applegate, L.E.: Membrane separation processes. Chem. Eng. 91, 64 (1984)

Benedict, M., Pigford, T.H., Levi, H.W.: Nuclear Chemical Engineering, 2nd edn. McGraw-Hill, NY (1981)

Bhadra, S.J., Ebner, A.D., Ritter, J.A.: Carbon monoxide isotope enrichment and separation by pressure swing adsorption. Adsorption 19, 11 (2013)

Chang, F.H., Vogt, H.K., Krochmalnek, L.S., Sood, S.K., Bartoszek, F.E., Woodall, K.B., Robins J.R.: Producing carbon-14 isotope from spent resin waste. US Patent 5,286,468, 1994

Cheh, C.H.: Advances in preparative gas chromatography for hydrogen isotope separation. J. Chromatogr. A 658, 283 (1994)

Cohen, K.: The theory of isotope separation separation as applied to the large scale production of uranium. McGraw-Hill, New York (1951)

Cohen, K., Kaplan, I.: Absolute efficiencies of isotope separation by counter-current centrifuges: a new counter-current centrifuge. Report No. A-101, Columbia University, New York, 1942

Fachinger, J., Lensa, W.V., Podruhzina, T.: Decontamination of nuclear graphite. Nucl. Eng. Des. 238, 3086 (2008)

Geankoplis, C.J.: Transport Processes and Separation Process Principles, 4th edn. Prentice-Hall, Upper saddle River (2003)

Hill, F.B., Grzetic, V.: Cascades for hydrogen isotope separation using metal hydride. J. Less-Common Met. 89, 399 (1983)

Horen, A.S., Lee, M.W.: Metal hydride based isotope separation—Large scale operations. In: Proceedings of the Fourth ANS Topical Meeting on Tritium Technology in Fission, Fusion and Isotopic Applications, New Mexico, 1991

Izumi, J., Yasutake, A., Kobayashi, S., Shikichi, A., Kinugasa, A., Kohanawa, O., Okumura, N., Kanda, T., Izumi, Y., Saigusa, M., Oguri, D., Inoue, T., Oumori, S.: 14CO and 12CO separation on Na-X using pressure swing adsorption at low temperatures. Adsorption 11, 817 (2005)

Keshaviah, V.R., C.E. Jr. Hamrin: Progress Report, U.S. Atomic Energy Commission. Rept. No. ORD-3913-2, 1972

Kholpanov, L.P., Sulaberidze, G.A., Potapov, D.V., Chuzhinov, V.A.: Multicomponent isotope separating cascade with losses. Chem. Eng. Proc. 36, 189 (1997)

Letokhov, V.S.: USSR Patent N 65743, 1970

Lonsdale, H.K.: The growth of membrane technology. J. Membr. Sci. 10, 81 (1982)

Mason, J.B., Bradbury, D.: Process for the treatment of radioactive graphite. US Patent 6,625,248, 2002

McInteer, B.B.: Fractional Distillation for Carbon Isotope. Separation. Las Alamos National Laboratory Report, LANL-78-76, 1978

O’Farrell, P.H.: Method of isotope enrichment. US Patent 4,290,855, 1981

Ortman, M.S., Heung, L.K., Nobile A., Rabun, R.L.: Tritium processing at the Savanah River Site (SRS): Present and future. In: Proceedings of the 36th National Symposium of the American Vacuum Society, MA, 1989

Patrick, R.R., Schrodt, J.T., Kermode, R.I.: Thermal parametric pumping of air-SO2. Separation Sci. 7, 331 (1972)

Pratt, H.R.C.: Countercurrent separation processes. Elsevier, Amsterdam (1967)

Robieux, J., Auclair, J.M.: Separation of isotopes. French Patent 1,391,738, 1965

Shanahan, K.L., Holder, J.S., Wermer, J.R.: Tritium aging effects in palladium on kieselguhr. J. Alloy. Compd. 293–295, 62 (1999)

van Keken, P.E., Yuen, D.A., Petzold, L.R.: DASPK: A new high order and adaptive time-integration technique with applications to mantle convection with strongly temperature-and pressure-dependent rheology. Geophys. Astrophys. Fluid Dyn. 80, 57 (1995)

Whitley, S.: Review of the gas centrifuge until 1962. Part I: Principles of separation physics. Rev. Modern Phys. 1984(56), 41 (1984)

Acknowledgments

The authors gratefully acknowledge financial support provided in part by the National Space Biomedical Research Institute through NASA NCC9-58, in part by the SAGE Center at the University of South Carolina, and in part by the Process Science and Technology Center, a consortium composed of the University of Texas at Austin, the University of South Carolina, and the Texas A&M University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhadra, S.J., Ebner, A.D., van Brunt, V. et al. Ideal cascade theory applied to carbon monoxide isotope separation by pressure swing adsorption. Adsorption 21, 467–478 (2015). https://doi.org/10.1007/s10450-015-9687-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-015-9687-3