Abstract

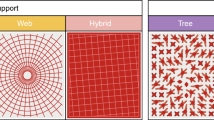

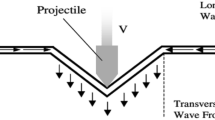

Basalt and Kevlar materials are high-performance reinforcements used in armor systems. The present work presented that the combination of natural fiber (basalt) with synthetic fiber (Kevlar) and alumina tile composites improves ballistic performance. The partial replacement of basalt encourages the use of natural reinforcement for the development of eco-friendly armor. Continuum damage mechanics (CDM) based modeling is used with a high strain rate and implemented based on Yen’s criteria. Cohesive elements are used at inter-layers for modeling the damage evolution. The damage initiation and propagation model is created and implemented as a user-defined subroutine in the ABAQUS finite element (FE) code (VUMAT). Parametric studies are performed by varying the stacking sequence of Kevlar 3D (K3D) and basalt 3D (B3D) layers and the best stacking is used with ceramic (alumina) material. The optimum stacking sequence of composite laminate thickness is investigated to design the light weight body armour and the better results are used to reduce the thickness of the panel, which is the key factor to design any armor panel. Results revealed the panels with basalt composite (B16) impacting with FSP impactor and alumina/Kevlar/basalt composite (C1K7B8) impacting with 9 mm FMJ impactor improved the ballistic performance as compared to H16, K8H8 and K8B8 stacking sequences.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- K3D:

-

3D Kevlar lamina

- B3D:

-

3D Basalt lamina

- H3D:

-

3D basalt/Kevlar hybrid lamina

- B16:

-

16 Basalt laminae

- H16:

-

16 Kevlar laminae

- K8H8:

-

Eight 3D Kevlar laminae and eight 3D hybrid laminae

- K8B8:

-

Eight 3D Kevlar laminae and eight 3D Basalt laminae

- C1K7B8:

-

One ceramic tile, seven Kevlar laminae and eight basalt laminae

- KPL:

-

2D plane Kevlar lamina

- BPL:

-

2D plane basalt lamina

- HPL:

-

Hybrid lamina of 2D

- \(E_X, E_Y\), \(E_Z\) (GPa):

-

Modulus of elasticity in weft, warp, out of plane direction

- \(\nu _X, \nu _Y, \nu _Z\) :

-

Poisson’s ratios

- \(G_{XY}, G_{YZ}\), \(G_{XZ}\) (GPa):

-

Modulus of rigidity in xy, xy, xy direction

- \(\epsilon _X\), \(\epsilon _Y\), \(\epsilon _Z\) :

-

Compressive strain in x,y and z direction

- \(S_{XT}, S_{XC}\) (MPa):

-

Tensile and compressive strength in axial direction

- \(S_{YT}, S_{YC}\) (MPa):

-

Tensile and compressive strength in transverse direction

- \(S_{ZT}\) (MPa):

-

Tensile strength in out of plane direction

- \(S_{XFS}, S_{YFS}\) (MPa):

-

Fiber shear strength in x and y direction

- \(S_{YZO}, S_{XZO}\) (MPa):

-

Tensile modes corresponding shear strengths in the yz and xz directions

- m:

-

Material constant

- \(\phi ^._i\) :

-

Damag growth rate mode

- \(\overline{\omega }_j\) :

-

Damage variable

- \(\gamma _i\) :

-

Weibull distribution

- \(S_{FC}\) (MPa):

-

Fiber crush strength

- N :

-

Number of nodes

- \(S_{XY}\) (MPa):

-

Matrix shear failure strength

- \(\rho\) (g/cm3):

-

Density

- \(\overline{\omega }^._j\) :

-

Growth rate damage variable

- \(S_{SR}\) :

-

Residual sliding strength

- \(\eta\), \(\zeta\) :

-

Iso-parametric coordinates

- \(S_{XCR}\) :

-

Residual strength in x direction

- \(S_{YCR}\) :

-

Residual strength in y direction

- t (mm):

-

Thickness of lamina

- \(\langle \rangle\) :

-

Macaulay brackets

- \(\phi\) :

-

Coulomb’s friction angle

- [C] :

-

Stiffness Matrix

- [\(S^*\)]:

-

Compliance matrix

- [q]:

-

Coupling matrix

- \(f_i\) :

-

Fiber damage modes in different strains \(i = 1,2,3...\)

References

Zhu, W., Liu, J., Wei, X.: A multiscale model for the prediction of ballistic performance of fiber-reinforced composites. Int. J. Impact Eng. 154, (2021). https://doi.org/10.1016/j.ijimpeng.2021.103889

Wei, Q., Yang, D., Gu, B., Sun, B.: Numerical and experimental investigation on 3D angle interlock woven fabric under ballistic impact. Compos. Struct. 266, 113778 (2021). https://doi.org/10.1016/j.compstruct.2021.113778

Arpatappeh, F.A., Azghan, M.A., Eslami-Farsani, R.: The effect of stacking sequence of basalt and Kevlar fibers on the Charpy impact behavior of hybrid composites and fiber metal laminates. Proc. Inst. Mech. Eng. Part L. J. Mater. Des. Appl. 234, 3270–3279 (2020). https://doi.org/10.1177/0954406220914325

Pincheira, G., Canales, C., Medina, C., Fernández, E., Flores, P.: Influence of aramid fibers on the mechanical behavior of a hybrid carbon-aramid-reinforced epoxy composite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 232, 58–66 (2018). https://doi.org/10.1177/1464420715612827

Scazzosi, R., Manes, A., Giglio, M.: Analytical model of high-velocity impact of a deformable projectile against textile-based composites. J. Mater. Eng. Perform. 28, 3247–3255 (2019). https://doi.org/10.1007/s11665-019-04026-x

He, J., He, L., Yang, B.: Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation. Sci. Eng. Compos. Mater. 26, 1–11 (2019). https://doi.org/10.1515/secm-2017-0222

Abtew, M.A., Boussu, F., Bruniaux, P., Loghin, C., Cristian, I.: Ballistic impact mechanisms - A review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 223, 110966 (2019). https://doi.org/10.1016/j.compstruct.2019.110966

Silva, M.A.G., Cismaşiu, C., Chiorean, C.G.: Numerical simulation of ballistic impact on composite laminates. Int J Impact Eng 31, 289–306 (2005). https://doi.org/10.1016/j.ijimpeng.2004.01.011

Ramadhan, A.A., Abu Talib, A.R., Mohd Rafie, A.S., Zahari, R.: The influence of impact on composite armour system Kevlar-29/polyester- Al2O3. IOP Conf. Ser. Mater. Sci. Eng. 36, (2012). https://doi.org/10.1088/1757-899X/36/1/012028

Bandaru, A.K., Patel, S., Sachan, Y., Ahmad, S., Alagirusamy, R., Bhatnagar, N.: Mechanical behavior of Kevlar/basalt reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 90, 642–652 (2016). https://doi.org/10.1016/j.compositesa.2016.08.031

Bandaru, A.K., Patel, S., Sachan, Y., Ahmad, S., Alagirusamy, R., Bhatnagar, N.: Mechanical characterization of 3D angle-interlock Kevlar/basalt reinforced polypropylene composites. Polym. Test. 55, 238–246 (2016)

Bandaru, A.K., Patel, S., Ahmad, S., Bhatnagar, N.: An experimental and numerical investigation on the low-velocity impact response of thermoplastic hybrid composites. J. Compos. Mater. 52, 877–889 (2018)

Bandaru, A.K., Ahmad, S., Bhatnagar, N.: Ballistic performance of hybrid thermoplastic composite armors reinforced with Kevlar and basalt fabrics. Compos. Part A Appl. Sci. Manuf. 97, 151–165 (2017). https://doi.org/10.1016/j.compositesa.2016.12.007

Mousavi, M.V., Khoramishad, H.: Investigation of energy absorption in hybridized fiber-reinforced polymer composites under high-velocity impact loading. Int. J. Impact. Eng. 103692, (2020). https://doi.org/10.1016/j.ijimpeng.2020.103692

Santhosh, M.S., Sasikumar, R., Thangavel, T., Pradeep, A.: Fabrication and characterization of Basalt / Kevlar / Aluminium Fiber Metal Laminates for automobile applications. 14, 1–9 (2019)

Ansari, M.M., Chakrabarti, A.: Impact behavior of FRP composite plate under low to hyper velocity impact. Compos. Part B Eng. 95, 462–474 (2016). https://doi.org/10.1016/j.compositesb.2016.04.021

Yen, C.F.: A ballistic material model for continuous-fiber reinforced composites. Int. J. Impact Eng. 46, 11–22 (2012). https://doi.org/10.1016/j.ijimpeng.2011.12.007

Olmedo, A., Romualdo, G., Feito, N., Loya, J.A.: Behavior of a new combat helmet design against ballistic impact experimental and numerical analysis. Pass 2016 (2016)

Nunes, S.G., Scazzosi, R., Manes, A., Amico, S.C., de Amorim Júnior, W.F., Giglio, M.: Influence of projectile and thickness on the ballistic behavior of aramid composites: experimental and numerical study. Int. J. Impact Eng. 132, 103307 (2019). https://doi.org/10.1016/j.ijimpeng.2019.05.021

Palta, E., Fang, H., Weggel, D.C.: Finite element analysis of the Advanced Combat Helmet under various ballistic impacts. Int. J. Impact Eng. 112, 125–143 (2018). https://doi.org/10.1016/j.ijimpeng.2017.10.010

Tham, C.Y., Tan, V.B.C., Lee, H.P.: Ballistic impact of a KEVLAR® helmet: experiment and simulations. Int. J. Impact Eng. 35, 304–318 (2008). https://doi.org/10.1016/j.ijimpeng.2007.03.008

Patel, S., Guedes Soares, C.: System probability of failure and sensitivity analyses of composite plates under low velocity impact. Compos. Struct. 180, 1022–1031 (2017). https://doi.org/10.1016/j.compstruct.2017.08.054

Patel, S., Ahmad, S., Mahajan, P.: Thin-Walled Structures Safety assessment of composite beam under ballistic impact. Thin Walled Struct. 126, 162–170 (2018). https://doi.org/10.1016/j.tws.2017.05.027

Pathak, R.K., Patel, S., Gupta, V.K.: Efficient design of Kevlar / basalt hybrid composite laminates under ballistic impact. Adv. Compos. Mater. 00, 1–22 (2022). https://doi.org/10.1080/09243046.2022.2076022

Manigandan, S.: Computational investigation of high velocity ballistic impact test on Kevlar 149. Appl. Mech. Mater. 766–767, 1133–1138 (2015). https://doi.org/10.4028/www.scientific.net/amm.766-767.1133

Dhuban, S.B., Karuppanan, S., Mengal, A.N., Patil, S.S.: Effect of fiber orientation and ply stacking sequence on buckling behaviour of basalt-carbon hybrid composite laminates. Indian J. Eng. Mater. Sci. 24, 187–193 (2017)

Bandaru, A.K., Patel, S., Sachan, Y., Alagirusamy, R., Bhatnagar, N., Ahmad, S.: Low velocity impact response of 3D angle-interlock Kevlar/basalt reinforced polypropylene composites. Mater. Des. 105, 323–332 (2016). https://doi.org/10.1016/j.matdes.2016.05.075

Tirillò, J., Ferrante, L., Sarasini, F., Lampani, L., Barbero, E., Sánchez-Sáez, S., Valente, T., Gaudenzi, P.: High velocity impact behaviour of hybrid basalt-carbon/epoxy composites. Compos. Struct. 168, 305–312 (2017)

Shi, Y., Swait, T., Soutis, C.: Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 94, 2902–2913 (2012). https://doi.org/10.1016/j.compstruct.2012.03.039

Shi, Y., Soutis, C.: Modelling low velocity impact induced damage in composite laminates. Mech. Adv. Mater. Mod. Process 3, (2017). https://doi.org/10.1186/s40759-017-0029-x

Bandaru, A.K., Ahmad, S.: Modeling of progressive damage for composites under ballistic impact (2016). https://doi.org/10.1016/j.compositesb.2016.02.053

Holmquist, T.J., Johnson, G.R.: Characterization and evaluation of silicon carbide for high-velocity impact. J. Appl. Phys. 97, (2005). https://doi.org/10.1063/1.1881798

Scazzosi, R., Brejão de Souza, S.D., Amico, S.C., Giglio, M., Manes, A.: Experimental and numerical evaluation of the perforation resistance of multi-layered alumina/aramid fiber ballistic shield impacted by an armor-piercing projectile. Compos. Part B Eng. 230, (2022). https://doi.org/10.1016/j.compositesb.2021.109488

Gregori, D., Scazzosi, R., Nunes, S.G., Amico, S.C., Giglio, M., Manes, A.: Analytical and numerical modelling of high-velocity impact on multilayer alumina/aramid fiber composite ballistic shields: improvement in modelling approaches. Compos. Part B Eng. 187. https://doi.org/10.1016/j.compositesb.2020.107830

Johnson, G.R.: Dynamic analysis of a torsion test specimen including heat conduction and plastic flow. ASME J. Eng. Mater. Technol. 103(3) (July 1981). https://doi.org/10.1115/1.3225001

Børvik, T., Dey, S., Olovsson, L.: Penetration of granular materials by small-arms bullets. Int. J. Impact Eng. 75, 123–139 (2015). https://doi.org/10.1016/j.ijimpeng.2014.07.016

Saleh, M., Edwards, L., Crouch, I.G.: Numerical modelling and computer simulations. Elsevier Ltd (2017)

Johnson, G.R., Holmquist, T.J.: 1994, An improved computational constitutive model for brittle materials. High-Pressure Science and Technology, American Institute of Physics (1992). https://doi.org/10.1063/1.46199

Goda, I., Girardot, J.: A computational framework for energy absorption and damage assessment of laminated composites under ballistic impact and new insights into target parameters. Aerosp. Sci. Technol. 115, 106835 (2021). https://doi.org/10.1016/j.ast.2021.106835

Caçoilo, A., Mourão, R., Teixeira-Dias, F., Azevedo, A., Coghe, F., Valente, R.A.F.: Modelling ballistic impact on military helmets: the relevance of projectile plasticity. Def. Technol. 17, 1699–1711 (2021). https://doi.org/10.1016/j.dt.2020.09.011

Guo, G., Alam, S., Peel, L.D.: An investigation of the effect of a Kevlar-29 composite cover layer on the penetration behavior of a ceramic armor system against 7.62 mm APM2 projectiles. Int. J. Impact Eng. 157, (2021) https://doi.org/10.1016/j.ijimpeng.2021.104000

Rajole, S., Ravishankar, K.S., Kulkarni, S.M.: Performance study of jute-epoxy composites/sandwiches under normal ballistic impact. Def. Technol. 16, 947–955 (2020). https://doi.org/10.1016/j.dt.2019.11.011

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pathak, R.K., Patel, S., Gupta, V.K. et al. A Computational Analysis of the High-velocity Impact Performance of Lightweight 3D Hybrid Composite Armors. Appl Compos Mater 30, 727–751 (2023). https://doi.org/10.1007/s10443-023-10112-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-023-10112-0