Abstract

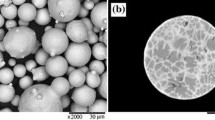

The life of high temperature coating mainly depends on its oxidation resistance and bonding strength with the substrate. SiCnws / SiC coatings were prepared by a self-made two temperature reaction system and chemical vapor deposition method. The oxidation resistance of the composite coating at 900 ℃ and 1500 ℃ and the thermal shock resistance at 1500 ℃ were studied. The fracture toughness and bonding strength of the composite coating were increased by 53.8% and 9.8 times, respectively, due to the stable mechanical linkage effect between the bamboo like SiC nanowires with special nodes and SiC. Due to the healing effect of glass phase SiO2, the weight loss rate of bamboo like SiCnws / SiC coating sample after oxidation at 900 ℃ for 30 h is about 5.28%, and that after isothermal oxidation at 1500 ℃ for 60 h is only 0.74%. In addition, bamboo like SiCnws can effectively alleviate the thermal expansion coefficient mismatch between SiC coating and substrate. After 25 thermal shock cycles, the final oxidation weight loss rate of composite coating is only 2.03%.

Similar content being viewed by others

References

Djugum, R., Sharp, K.: The fabrication and performance of C/C composites impregnated with TaC filler. Carbon 115, 105–115 (2017)

Cao, X.Q., Vassen, R., Stoever, D.: Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 24, 1–10 (2004). https://doi.org/10.1016/S0955-2219(03)00129-8

Zhuang, L., Fu, Q.-G., Tan, B.-Y., Guo, Y.-A., Ren, Q.-W., Li, H.-J., Li, B., Zhang, J.-P.: Ablation behaviour of C/C and C/C-ZrC-SiC composites with cone-shaped holes under an oxyacetylene flame. Corros. Sci. 102, 84–92 (2016)

B W Z A, B P X, B W L, et al. Microstructural evolution of SiC coating on C/C composites exposed to 1500°C in ambient air[J]. Ceramics International, (2019), 45(1):854–860.

Jin, X., Fan, X., Lu, C., Wang, T.: Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. J. Eur. Ceram. Soc. 38, 1–28 (2018)

P. Chowdhury, H. Sehitoglu, R. Rateick, Damage tolerance of carbon-carbon composites in aerospace application, Carbon 126 (2018) 382e393.

Zhou, W., Long, L., Xiao, P., et al.: Comparison in dielectric and microwave absorption properties of SiC coated carbon fibers with PyC and BN interphases[J]. Surf. Coat. Technol. 359, 272–277 (2018)

Zhou W, Li Y, Long L, et al. High‐temperature electromagnetic wave absorption properties of Cf/SiCNFs/Si3N4 composites[J]. Journal of the American Ceramic Society, (2020).

Long L, Xu J, Luo H, et al. Dielectric response and electromagnetic wave absorption of novel macroporous short carbon fibers/mullite composites[J]. Journal of the American Ceramic Society, (2020).

Zhou W, Long Y. Mechanical properties of CVD-SiC coatings with Si impurity[J]. Ceramics International, (2018), 44: S0272884218323332-.

E.L. Corral, R.E. Loehman, Ultra-high-temperature ceramic coatings for oxidation protection of carbon-carbon composites, J. Am. Ceram. Soc. 91(2008) 1495e1502.

Q.G. Fu, J.Y. Jing, B.Y. Tan, R.M. Yuan, L. Zhuang, L. Li, Nanowire-toughened transition layer to improve the oxidation resistance of SiC-MoSi2-ZrB2coating for C/C composites, Corrosion Sci. 111 (2016) 259e266.

Y. Yang, K.Z. Li, Z.G. Zhao, G.X. Liu, HfC-ZrC-SiC multiphase protective coating for SiC-coated C/C composites prepared by supersonic atmospheric plasma spraying, Ceram. Int. 43 (1) (2016) 1495e1503.

Liu, C., Cheng, L., Luan, X., et al.: High-temperature fatigue behavior of SiC-coated carbon/carbon composites in oxidizing atmosphere[J]. J. Eur. Ceram. Soc. 29(3), 481–487 (2009)

Zeng, X.R., Li, H.J., Yang, Z., Kang, M.K.: Investigation of microstructure for oxidation protection coated C/C composites. Trans. Met. Heat Treat. 21, 64 (2000)

Fu, Q.-G., Li, H.-J., Li, K.-Z., Tong, K.: A SiC-Mo-W coating to protect SiC-coated carbon/carbon composites against oxidation. J. Am. Ceram. Soc. 92, 2132–2135 (2009)

Zishan, C., Hejun, L., Qiangang, F.: SiC wear resistance coating with added Ni, for carbon/carbon composites. Surf. Coating. Technol. 213, 207–215 (2012)

Lin X, Xinchao L, Liyong N, et al. Ablation behavior of functional gradient ceramic coating for porous carbon-bonded carbon fiber composites[J]. Corrosion Science, 2018, 142: S0010938X17322059-.

Zhou, W., Long, L., Xiao, P., et al.: Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties[J]. Ceram. Int. 43(7), 5628–5634 (2017)

Xia X, Li Y, Long L, et al. Modeling for the electromagnetic properties and EMI shielding of Cf/mullite composites in the gigahertz range[J]. Journal of the European Ceramic Society, (2020).

Liu, Y., Wan, J., Zuo, X., et al.: Oxidation behavior of 2D C/SiC composites coated with multi-layer SiC/Si–B–C/SiC coatings under wet oxygen atmosphere[J]. Applied Surface ence 353, 214–223 (2015)

Fei Liu, Li H, Gu S, et al. Microstructure and oxidation property of CrSi2-ZrSi2-Y2O3/SiC coating prepared on C/C composites by supersonic atmosphere plasma spraying[J]. Surface and Coatings Technology, (2019).

Yanhui, C., Qiangang, F., Cuiwei, C., et al.: SiC nanowire-toughened SiC-MoSi2-CrSi2 oxidation protective coating for carbon/carbon composites[J]. Surf. Coat. Technol. 205(2), 413–418 (2010)

Chu, Y., Fu, Q., Li, H., et al.: Effect of SiC nanowires on the mechanical and oxidation protective ability of SiC coating for C/C composites[J]. J. Am. Ceram. Soc. 95(2), 739–745 (2012)

Qiang, X., Li, H., Zhang, Y., et al.: Fabrication and thermal shock resistance of in situ SiC nanowire-SiC/SiC coating for carbon/carbon composites[J]. Corros. Sci. 59, 343–347 (2012)

Chu, Y., Li, H., Li, L., et al.: Oxidation protection of C/C composites by ultra long SiC nanowire-reinforced SiC-Si coating[J]. Corros. Sci. 84, 204–208 (2014)

Jianfeng, H., Lei, Z., Liyun, C., et al.: Effect of the incorporation of SiC nanowire on mullite/SiC protective coating for carbon/carbon composites[J]. Corros. Sci. 107, 85–95 (2016)

Zhuang, L., Fu, Q.G., Yu, X.: Improved thermal shock resistance of SiCnw/PyC core-shell structure-toughened CVD-SiC coating[J]. J. Eur. Ceram. Soc. 38(7), 2808–2814 (2018)

Chu, Y., Li, H., Fu, Q., et al.: Oxidation protection of SiC-coated C/C composites by SiC nanowire-toughened CrSi2-SiC-Si coating[J]. Corros. Sci. 55, 394–400 (2012)

Zhang, Y., Zhang, P., Ren, J., et al.: SiC nanowire-toughened MoSi2-WSi2-SiC-Si multiphase coating for improved oxidation resistance of C/C composites[J]. Ceram. Int. 42(11), 12573–12580 (2016)

Wang, P.P., Tong, M.D., Wang, H.H., et al.: Gradient HfB2-SiC multilayer oxidation resistant coating for C/C composites[J]. Ceram. Int. 44(17), 20968–20973 (2018)

Li B, Mao B, Wang X, et al. Fabrication and frictional wear property of bamboo-like SiC nanowires reinforced SiC coating[J]. Surface and Coatings Technology, (2020):125647.

Wang, Y., Chen, Z., Yu, S., et al.: A novel ultra-light reticulated SiC foam with hollow skeleton[J]. J. Eur. Ceram. Soc. 37(1), 53–59 (2017)

Jia D C, Zhou Y. Research progress in thermal shock resistance of ceramic materials[J]. Materials science and technology. (1993), 04:101–107. (China)

Acknowledgements

The work reported here was supported by ‘the Fundamental Research Funds for the Central Universities, NO. NS2019035’.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, B., Wang, X., Mao, B. et al. Bamboo like SiC Nanowires Grown in a Dual-Temperature Zone Reaction System Enhance the Oxidation and Thermal Shock Resistance of SiC Coatings. Appl Compos Mater 28, 1–15 (2021). https://doi.org/10.1007/s10443-020-09845-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09845-z