Abstract

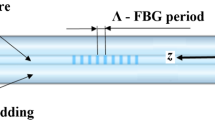

The paper is devoted to combined computational and experimental approach for estimation of the elastic mechanical properties of structures made of laminate polymer composite materials (PCM). The computational component of the technique is connected with numerical simulation of mechanical behavior during quasistatic deformation of structures made of PCM. The experimental component is based on measurement of strains by fiber-optic strain sensors (FOSS) with Bragg gratings (FBG sensors), embedded in composite laminates or attached to them. The principle of the proposed method is based on the comparison of the data from FBG sensors, placed in the predetermined control points in the composite structure, with the data of numerical finite element modelling of the same structure. To refine the elastic constants in accordance with the information received from the FBG sensors, an algorithm is proposed, according to which the inverse problems are solved in order to ensure that the numerical and experimental results coincide with the specified accuracy. The implementation of the algorithm is demonstrated on the example case studies.

Similar content being viewed by others

References

Staszewski, W.J., Mahzan, S., Traynor, R.: Health monitoring of aerospace composite structures - active and passive approach. Compos. Sci. Technol. 69, 1678–1685 (2009). https://doi.org/10.1016/j.compscitech.2008.09.034

de Oliveira, R., Frazão, O., Santos, J., Marques, A.: Optic fibre sensor for real-time damage detection in smart composite. Comput. Struct. 82, 1315–1321 (2004). https://doi.org/10.1016/j.compstruc.2004.03.028

Diamanti, K., Soutis, C.: Structural health monitoring techniques for aircraft composite structures. Prog. Aerosp. Sci. 46, 342–352 (2010). https://doi.org/10.1016/j.paerosci.2010.05.001

Du, W., Tao, X.M., Tam, H.Y., Choy, C.L.: Fundamentals and applications of optical fiber Bragg grating sensors to textile structural composites. Compos. Struct. 42, 217–229 (1998). https://doi.org/10.1016/S0263-8223(98)00045-2

Di Sante, R., Donati, L., Troiani, E., Proli, P.: Reliability and accuracy of embedded fiber Bragg grating sensors for strain monitoring in advanced composite structures. Met. Mater. Int. 20, 537–543 (2014). https://doi.org/10.1007/s12540-014-3020-7

Lau, K.-T.: Structural health monitoring for smart composites using embedded FBG sensor technology. Mater. Sci. Technol. 30, 1642–1654 (2014). https://doi.org/10.1179/1743284714Y.0000000608

Kuang, K.S.C., Kenny, R., Whelan, M.P., Cantwell, W.J., Chalker, P.R.: Embedded fibre Bragg grating sensors in advanced composite materials. Compos. Sci. Technol. 61, 1379–1387 (2001). https://doi.org/10.1016/S0266-3538(01)00037-9

Majumder, M., Gangopadhyay, T.K., Chakraborty, A.K., Dasgupta, K., Bhattacharya, D.K.: Fibre Bragg gratings in structural health monitoring-present status and applications. Sensors Actuators A Phys. 147, 150–164 (2008). https://doi.org/10.1016/j.sna.2008.04.008

Hafizi, Z.M., Epaarachchi, J., Lau, K.T.: Impact location determination on thin laminated composite plates using an NIR-FBG sensor system. Meas. J. Int. Meas. Confed. 61, 51–57 (2015). https://doi.org/10.1016/j.measurement.2014.08.040

Tao, X.M.: Integration of fibre-optic sensors in smart textile composites: design and fabrication. J. Text. Inst. 91, 448–459 (2000). https://doi.org/10.1080/00405000008659520

Fan, Y., Kahrizi, M.: Characterization of a FBG strain gage array embedded in composite structure. Sensors Actuators A Phys. 121, 297–305 (2005). https://doi.org/10.1016/j.sna.2005.01.021

Kablov, E.N., Sivakov, D.V., Gulyaev, I.N., Sorokin, K.V., Fedotov, M.Y., Dianov, E.M., Vasil’ev, S.A., Medvedkov, O.I.: Application of optical fiber as strain gauges in polymer composite materials. Polym. Sci. Ser. D. 4, 246–251 (2011). https://doi.org/10.1134/S1995421211030063

Alemohammad, H.: Opto-mechanical modeling of Fiber Bragg grating sensors. Elsevier Inc., Amsterdam (2018)

Matveenko, V.P., Shardakov, I.N., Voronkov, A.A., Kosheleva, N.A., Lobanov, D.S., Serovaev, G.S., Spaskova, E.M., Shipunov, G.S.: Measurement of strains by optical fiber Bragg grating sensors embedded into polymer composite material. Struct. Control. Health Monit. 25, e2118 (2018). https://doi.org/10.1002/stc.2118

Kinet, D., Mégret, P., Goossen, K.W., Qiu, L., Heider, D., Caucheteur, C.: Fiber Bragg grating sensors toward structural health monitoring in composite materials: challenges and solutions. Sensors (Basel). 14, 7394–7419 (2014). https://doi.org/10.3390/s140407394

Nair, A.K., Machavaram, V.R., Mahendran, R.S., Pandita, S.D., Paget, C., Barrow, C., Fernando, G.F.: Process monitoring of fibre reinforced composites using a multi-measurand fibre-optic sensor. Sensors Actuators B Chem. 212, 93–106 (2015). https://doi.org/10.1016/j.snb.2015.01.085

Luyckx, G., Voet, E., Lammens, N., Degrieck, J.: Strain measurements of composite laminates with embedded fibre bragg gratings: criticism and opportunities for research. Sensors. 11, 384–408 (2011). https://doi.org/10.3390/s110100384

Cai, J., Qiu, L., Yuan, S., Shi, S., Liu, P., Liang, D., Shi, L., Liu, P., Liang, D.: Structural health monitoring for composite materials. Compos. their Appl. 37–58 (2012). doi:https://doi.org/10.5772/48215

Li, X., Prinz, F.: Embedded Fiber Bragg grating sensors in polymer structures fabricated by layered manufacturing. J. Manuf. Process. 5, 78–86 (2003). https://doi.org/10.1016/S1526-6125(03)70043-7

Tashkinov, M., Matveenko, V.: Method of assessment of mechanical characteristics of quasi-isotropic composite laminates using experimental data from fiber- optic strain sensors. Procedia Struct. Integr. 5, 577–583 (2017). https://doi.org/10.1016/j.prostr.2017.07.017

Tserpes, K.I., Karachalios, V., Giannopoulos, I., Prentzias, V., Ruzek, R.: Strain and damage monitoring in CFRP fuselage panels using fiber Bragg grating sensors. Part I: Design, manufacturing and impact testing. Compos. Struct. 107, 726–736 (2014). https://doi.org/10.1016/j.compstruct.2013.09.053

De Baere, I., Voet, E., Van Paepegem, W., Vlekken, J., Cnudde, V., Masschaele, B., Degrieck, J.: Strain monitoring in thermoplastic composites with optical fiber sensors: embedding process, visualization with micro-tomography, and fatigue results. J. Thermoplast. Compos. Mater. 20, 453–472 (2007). https://doi.org/10.1177/0892705707082325

Yashiro, S., Takeda, N., Okabe, T., Sekine, H.: A new approach to predicting multiple damage states in composite laminates with embedded FBG sensors. Compos. Sci. Technol. 65, 659–667 (2005). https://doi.org/10.1016/j.compscitech.2004.09.022

Beukema, R.P.: Embedding Technologies of FBG Sensors in Composites : Technologies , Applications and Practical Use. 6th Eur. Work. Struct. Heal. Monit. 1–8 (2012)

Geng, X., Jiang, M., Gao, L., Wang, Q., Jia, Y., Sui, Q., Jia, L., Li, D.: Sensing characteristics of FBG sensor embedded in CFRP laminate. Meas. J. Int. Meas. Confed. 98, 199–204 (2017). https://doi.org/10.1016/j.measurement.2016.12.003

Qiu, Y., Wang, Q.-B., Zhao, H.-T., Chen, J., Wang, Y.-Y.: Review on composite structural health monitoring based on fiber Bragg grating sensing principle. J. Shanghai Jiaotong Univ. 18, 129–139 (2013). https://doi.org/10.1007/s12204-013-1375-4

Yashiro, S., Okabe, T., Toyama, N., Takeda, N.: Monitoring damage in holed CFRP laminates using embedded chirped FBG sensors. Int. J. Solids Struct. 44, 603–613 (2007). https://doi.org/10.1016/j.ijsolstr.2006.05.004

Hu, H., Li, S., Wang, J., Wang, Y., Zu, L.: FBG-based real-time evaluation of transverse cracking in cross-ply laminates. Compos. Struct. 138, 151–160 (2016). https://doi.org/10.1016/j.compstruct.2015.11.037

Leduc, D., Lecieux, Y., Morvan, P.A., Lupi, C.: Architecture of optical fiber sensor for the simultaneous measurement of axial and radial strains. Smart Mater. Struct. 22, 075002 (2013). https://doi.org/10.1088/0964-1726/22/7/075002

Wang, H., Dai, J.-G.: Strain transfer analysis of fiber Bragg grating sensor assembled composite structures subjected to thermal loading. Compos. Part B Eng. 162, 303–313 (2018). https://doi.org/10.1016/j.compositesb.2018.11.013

Frieden, J., Cugnoni, J., Botsis, J., Gmür, T., Ćorić, D.: High-speed internal strain measurements in composite structures under dynamic load using embedded FBG sensors. Compos. Struct. 92, 1905–1912 (2010). https://doi.org/10.1016/j.compstruct.2010.01.007

Colpo, F., Humbert, L., Botsis, J.: Characterisation of residual stresses in a single fibre composite with FBG sensor. Compos. Sci. Technol. 67, 1830–1841 (2007). https://doi.org/10.1016/j.compscitech.2006.10.024

Zou, H., Liang, D., Zeng, J.: Dynamic strain measurement using two wavelength-matched fiber Bragg grating sensors interrogated by a cascaded long-period fiber grating. Opt. Lasers Eng. 50, 199–203 (2012). https://doi.org/10.1016/j.optlaseng.2011.09.005

Kim, S.-W., Kim, E.-H., Jeong, M.-S., Lee, I.: Damage evaluation and strain monitoring for composite cylinders using tin-coated FBG sensors under low-velocity impacts. Compos. Part B Eng. 74, 13–22 (2015). https://doi.org/10.1016/j.compositesb.2015.01.004

Cazzulani, G., Cinquemani, S., Comolli, L., Gardella, A., Resta, F.: Vibration control of smart structures using an array of Fiber Bragg grating sensors. Mechatronics. 24, 345–353 (2014). https://doi.org/10.1016/j.mechatronics.2013.07.014

Shrestha, P., Kim, J.H., Park, Y., Kim, C.G.: Impact localization on composite wing using 1D array FBG sensor and RMS/correlation based reference database algorithm. Compos. Struct. 125, 159–169 (2015). https://doi.org/10.1016/j.compstruct.2015.01.029

Frieden, J., Cugnoni, J., Botsis, J., Gmür, T.: Low energy impact damage monitoring of composites using dynamic strain signals from FBG sensors - part I: impact detection and localization. Compos. Struct. 94, 438–445 (2012). https://doi.org/10.1016/j.compstruct.2011.08.003

Dong, B., Xiao, L., Gong, Y., Wang, Y.: Cross-layerly embedded FBG in carbon fiber composites for self-modulated, intensity referenced and temperature insensitive microdisplacement measurement. Sensors Actuators A Phys. 199, 250–253 (2013). https://doi.org/10.1016/j.sna.2013.05.029

Bao, P., Yuan, M., Dong, S., Song, H., Xueb, J.: Fiber Bragg grating sensor fatigue crack real-time monitoring based on spectrum cross-correlation analysis. J. Sound Vib. 332, 43–57 (2013). https://doi.org/10.1016/j.jsv.2012.07.049

Di Sante, R.: Fibre optic sensors for structural health monitoring of aircraft composite structures: recent advances and applications. Sensors (Basel). 15, 18666–18713 (2015). https://doi.org/10.3390/s150818666

Ghoshal, A., Ayers, J., Gurvich, M., Urban, M., Bordick, N.: Experimental investigations in embedded sensing of composite components in aerospace vehicles. Compos. Part B Eng. 71, 52–62 (2015). https://doi.org/10.1016/j.compositesb.2014.10.050

Sbarufatti, C., Manes, A., Giglio, M.: Application of sensor technologies for local and distributed structural health monitoring. Struct. Control. Health Monit. 21, 1057–1083 (2014). https://doi.org/10.1002/stc.1632

Read, I.J., Foote, P.D.: Sea and flight trials of optical fibre Bragg grating strain sensing systems. Smart Mater. Struct. 10, 1085–1094 (2001)

Lee, J.-R., Ryu, C.-Y., Koo, B.-Y., Kang, S.-G., Hong, C.-S., Kim, C.-G.: In-flight health monitoring of a subscale wing using a fiber Bragg grating sensor system. Smart Mater. Struct. 12, 147–155 (2003). https://doi.org/10.1088/0964-1726/12/1/317

Wymore, M.L., Van Dam, J.E., Ceylan, H., Qiao, D.: A survey of health monitoring systems for wind turbines. Renew. Sust. Energ. Rev. 52, 976–990 (2015). https://doi.org/10.1016/j.rser.2015.07.110

Sierra-Pérez, J., Torres-Arredondo, M.A., Güemes, A.: Damage and nonlinearities detection in wind turbine blades based on strain field pattern recognition. FBGs, OBR and strain gauges comparison. Compos. Struct. 135, 156–166 (2016). https://doi.org/10.1016/j.compstruct.2015.08.137

Schubel, P.J., Crossley, R.J., Boateng, E.K.G., Hutchinson, J.R.: Review of structural health and cure monitoring techniques for large wind turbine blades. Renew. Energy. 51, 113–123 (2013). https://doi.org/10.1016/j.renene.2012.08.072

Hong, C.Y., Zhang, Y.F., Zhang, M.X., Leung, L.M.G., Liu, L.Q.: Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques, (2016)

Huang, A.B., Wang, C.C., Lee, J.T., Te Ho, Y.: Applications of FBG-based sensors to ground stability monitoring. J. Rock Mech. Geotech. Eng. 8, 513–520 (2016). https://doi.org/10.1016/j.jrmge.2016.01.007

Castellano, A., Foti, P., Fraddosio, A., Marzano, S., Piccioni, M.D.: Mechanical characterization of CFRP composites by ultrasonic immersion tests: experimental and numerical approaches. Compos. Part B Eng. 66, 299–310 (2014). https://doi.org/10.1016/j.compositesb.2014.04.024

Paterson, D.A.P., Ijomah, W., Windmill, J.F.C.: Elastic constant determination of unidirectional composite via ultrasonic bulk wave through transmission measurements: A review, (2018)

Kudela, P., Radzienski, M., Fiborek, P., Wandowski, T.: Elastic constants identification of woven fabric reinforced composites by using guided wave dispersion curves and genetic algorithm. Compos. Struct. 249, 112569 (2020). https://doi.org/10.1016/j.compstruct.2020.112569

Acosta-Flores, M., Jiménez-López, E., Chávez-Castillo, M., Molina-Ocampo, A., Delfín-Vázquez, J.J., Rodríguez-Ramírez, J.A.: Experimental method for obtaining the elastic properties of components of a laminated composite. Results Phys. 12, 1500–1505 (2019). https://doi.org/10.1016/j.rinp.2019.01.016

Ienny, P., Caro-Bretelle, A.-S., Pagnacco, E.: Identification from measurements of mechanical fields by finite element model updating strategies. Eur. J. Comput. Mech. 18, 353–376 (2009). https://doi.org/10.3166/ejcm.18.353-376

Bruno, L.: Mechanical characterization of composite materials by optical techniques: a review. Opt. Lasers Eng. 104, 192–203 (2018). https://doi.org/10.1016/j.optlaseng.2017.06.016

Tashkinov, M., Shardakov, I.: Numerical analysis of the effect of microscale components interaction on measurements of Fiber optic strain sensors used in composite structures. Adv. Mater. Sci. Eng. 2019, 1–8 (2019). https://doi.org/10.1155/2019/1714608

Anoshkin, A.N., Voronkov, A.A., Kosheleva, N.A., Matveenko, V.P., Serovaev, G.S., Spaskova, E.M., Shardakov, I.N., Shipunov, G.S.: Measurement of inhomogeneous strain fields by fiber optic sensors embedded in a polymer composite material. Mech. Solids. 51, 542–549 (2016). https://doi.org/10.3103/S0025654416050058

Guyard, R., Leduc, D., Lecieux, Y., Lupi, C.: Superposition of fiber Bragg and LPG gratings for embedded strain measurement. Comptes Rendus Phys. 17, 1027–1037 (2016). https://doi.org/10.1016/j.crhy.2016.07.014

Levenberg, K.: A method for the solution of certain non-linear probles in least squares. Q. Appl. Math. 11, 164–168 (1944)

Marquardt, D.: An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 11, 431–441 (1963). https://doi.org/10.1137/0111030

Fletcher, R.: Practical Methods of Optimization. John Wiley & Sons, Ltd, Chichester, West Sussex England (2000)

Rybicki, E.F., Kanninen, M.F.: A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 9, 931–938 (1977). https://doi.org/10.1016/0013-7944(77)90013-3

Raju, I.S.: Calculation of strain-energy release rates with higher order and singular finite elements. Eng. Fract. Mech. 28, 251–274 (1987). https://doi.org/10.1016/0013-7944(87)90220-7

Krueger, R.: Virtual crack closure technique: history, approach, and applications. Appl. Mech. Rev. 57, 109–143 (2004). https://doi.org/10.1115/1.1595677

Kenane, M., Benzeggagh, M.L.: Mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites under fatigue loading. Compos. Sci. Technol. 57, 597–605 (1997). https://doi.org/10.1016/S0266-3538(97)00021-3

Reinoso, J., Blázquez, A., París, F.: Damage simulations in composite structures in the presence of stress gradients. In: Modeling Damage, Fatigue and Failure of Composite Materials (2016)

Acknowledgements

This research was supported by the Russian Foundation for Basic Research, project No. 19-51-10003 (with the Royal Society).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tashkinov, M.A., Matveenko, V.P. Optimization of Elastic Properties of Composite Laminates Using Fiber-Optic Strain Sensors. Appl Compos Mater 27, 491–509 (2020). https://doi.org/10.1007/s10443-020-09827-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09827-1