Abstract

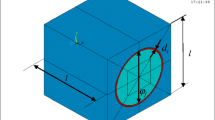

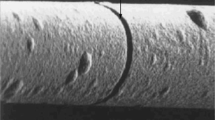

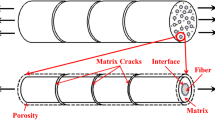

A model, based on the oxidation kinetics model of unidirectional C/SiC composite (between 400 °C and 800 °C in air, P = 100 KPa), is developed to predict the coefficient of thermal expansion (CTE) of 2.5D C/SiC composites. It takes into account (i) the changes versus time and temperature of the geometry of the notch resulting from the consumption by oxidation of the carbon interphase and fiber, (ii) the accumulation of oxidation damage of the carbon interphase and fiber in C/SiC microcomposite (one single filament) versus temperature during heating, (iii) the multiscale analysis of CTE of 2.5D C/SiC composites. The CTE of 2.5D C/SiC composites in warp direction during heating in air oxidizing environment are evaluated and validated in comparison to experimental data. The results indicate that the predicted CTE of 2.5D C/SiC composites in warp direction agree well with the experimental data.

Similar content being viewed by others

References

Naslain, R.: Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview ☆[J]. Compos. Sci. Technol. 64(2), 155–170 (2004)

Camus, G., Guillaumat, L., Baste, S.: Development of damage in a 2D woven C/SiC composite under mechanical loading: I. Mechanical characterization[J]. Compos. Sci. Technol. 56(12), 1363–1372 (1996)

Bouazzaoui, R.E., Baste, S., Camus, G.: Development of damage in a 2D woven C/SiC composite under mechanical loading: II. Ultrasonic characterization[J]. Compos. Sci. Technol. 56(96), 1373–1382 (1996)

Mei, H., Cheng, L.: Stress-dependence and time-dependence of the post-fatigue tensile behavior of carbon fiber reinforced SiC matrix composites[J]. Compos. Sci. Technol. 71(11), 1404–1409 (2011)

Gowayed, Y., Abouzeida, E., Smyth, I., et al.: The role of oxidation in time-dependent response of ceramic–matrix composites[J]. Composites Part B. 76, 20–30 (2015)

Yin, X., Cheng, L., Zhang, L., et al.: Oxidation behavior of 3D C/SiC composites in two oxidizing environments[J]. Compos. Sci. Technol. 61(7), 977–980 (2001)

Cheng, L., Xu, Y., Zhang, L., et al.: Effect of heat treatment on the thermal expansion of 2D and 3D C/SiC composites from room temperature to 1400 °C[J]. Carbon. 10(2), 113–118 (2002)

Abueidda, D.W., Dalaq, A.S., Al-Rub, R.K.A., et al.: Micromechanical finite element predictions of a reduced coefficient of thermal expansion for 3D periodic architectured interpenetrating phase composites[J]. Compos. Struct. 133, 85–97 (2015)

Wang, Y., Zhang, L., Cheng, L., et al.: Tensile performance and damage evolution of a 2.5-D C/SiC composite characterized by acoustic emission[J]. Appl. Compos. Mater. 15(4–6), 183–188 (2008)

Yu, L., Pan, B.: Experimental Study of tensile properties and deformation evolutions of 2D and 2.5D woven SiO2f/SiO2, composites using single-camera stereo-digital image correlation[J]. Composite Struct. (2018)

Li, Y., Xiao, P., Luo, H., et al.: Fatigue behavior and residual strength evolution of 2.5D C/C-SiC composites[J]. J. Eur. Ceram. Soc. 36(16), 3977–3985 (2016)

Lamouroux, F., Camus, G.: Oxidation effects on the mechanical properties of 2D woven C/SiC composites[J]. J. Eur. Ceram. Soc. 14(2), 177–188 (1994)

Costello, J.A., Tressler, R.E.: Oxidation kinetics of silicon carbide crystals and ceramics: I, in dry oxygen[J]. J. Am. Ceram. Soc. 69(9), 674–681 (2010)

Aparicio, M., Duran, A.: Infiltration of C/SiC composites with silica sol–gel solutions: part I. infiltration by dipping[J]. J. Mater. Res. 14(11), 4230–4238 (1999)

Aparicio, M., Duran, A.: Infiltration of C/SiC composites with silica sol-gel solutions: part II. Infiltration under isostatic pressure and oxidation resistance[J]. J. Mater. Res. 14(11), 4239–4245 (1999)

Besmann, T.M., Sheldon, B.W., Lowden, R.A., Stinton, D.P.: Vapor-phase fabrication and properties of continuous-filament ceramic composites[J]. Science. 253(5024), 1104–1109 (1991)

Cheng, L., Xu, Y., Zhang, L., et al.: Oxidation behavior of C–SiC composites with a Si–W coating from room temperature to 1500°C[J]. Mater. Sci. Eng. A. 38(15), 2133–2138 (2001)

Chen, X., Sun, Z., Sun, J., et al.: Simulation of degraded properties of 2D plain woven C/SiC composites under preloading oxidation atmosphere[J]. Appl. Compos. Mater. 24(6), 1–21 (2017)

Xu, Y., Zhang, P., Lu, H., et al.: Numerical modeling of oxidized C/SiC microcomposite in air oxidizing environments below 800 °C: microstructure and mechanical behavior[J]. J. Eur. Ceram. Soc. 35(13), 3401–3409 (2015)

Zhang, Q., Cheng, L., Zhang, L., et al.: Thermal expansion behavior of carbon fiber reinforced chemical-vapor-infiltrated silicon carbide composites from room temperature to 1400°C[J]. Mater. Lett. 60(27), 3245–3247 (2006)

Kumar, S., Kumar, A., Shukla, A., et al.: Investigation of thermal expansion of 3D-stitched C–SiC composites[J]. J. Eur. Ceram. Soc. 29(13), 2849–2855 (2009)

KONG: Analytical model of elastic modulus and coefficient of thermal expansion for 2.5D C/SiC composite[J]. J. Wuhan Univ. Technol. (Mater. Sci. Ed.). 28(3), 494–499 (2013)

Ai, S., Fu, H., He, R., et al.: Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature[J]. Mater. Des. 82, 181–188 (2015)

Li, Z., Yin, X., Ma, T., et al.: Bending and thermal expansion properties of 2.5D C/SiC composites[J]. Mater. Trans. 52(12), 2165–2167 (2011)

Sun, Z., Wang, Z., Song, Y.: Verification and prediction of elastic modulus of C/SiC composites under non-stress oxidation[J]. Acta Mater. Compos. Sin. 30(1), 172–179 (2013)

Zhang, J., Luan, X., Cheng, L., et al.: Damage evolution in 3D C_f/SiC composites in stressed oxidation environments[J]. J. Chin. Ceram. Soc. 38(5), 799–804 (2010)

Sun, Z., Shao, H., Chen, X., et al.: Analysis of residual performance of UD-CMC in oxidation atmosphere based on a notch-like oxidation model[J]. Appl. Compos. Mater. 23(5), 1–20 (2016)

Lamouroux, F., Camus, G., Thébault, J.: Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I, experimental approach[J]. J. Am. Ceram. Soc. 77(8), 2049–2057 (2010)

Halbig, M.C., JD, M.G.-C., Eckel, A.J., Brewer, D.N.: Oxidation kinetics and stress effects for the oxidation of continuous carbon fibers within a microcracked C/SiC ceramic matrix composite[J]. J. Am. Ceram. Soc. 91(2), 519–526 (2008)

Naslain, R., Lamon, J., Pailler, R., et al.: Micro/minicomposites: a useful approach to the design and development of non-oxide CMCs[J]. Compos. Part A Appl. Sci. Manuf. 30(4), 537–547 (1999)

Sun, Z., Kong, C., Niu, X., et al.: Optimization and reliability analysis of 2.5D C/SiC composites turbine Stator vane[J]. Appl. Compos. Mater. 21(5), 789–803 (2014)

Radcliffe, D.J., Rosenberg, H.M.: The thermal conductivity of glass-fibre and carbon-fibre/epoxy composites from 2 to 80 k[J]. Cryogenics. 22(5), 245–249 (1982)

Sauder, C., Lamon, J., Pailler, R.: Thermomechanical properties of carbon fibers at high temperatures (up to 2000 °C)[J]. Compos. Sci. Technol. 62(4), 499–504 (2002)

Pradere, C., Sauder, C.: Transverse and longitudinal coefficient of thermal expansion of carbon fibers at high temperatures (300–2500 K)[J]. Carbon. 46(14), 1874–1884 (2008)

Pradere, C., Batsale, J.C.: J.M. Goyhénèche, et al. thermal properties of carbon fibers at very high temperature[J]. Carbon. 47(3), 737–743 (2009)

Xu, Y., Ren, S., Zhang, W.: Thermal conductivities of plain woven C/SiC composite: micromechanical model considering PyC interphase thermal conductance and manufacture-induced voids[J]. Compos. Struct. (2018) S0263822317333846

Tsang, D.K.L., Marsden, B.J., Fok, S.L., et al.: Graphite thermal expansion relationship for different temperature ranges[J]. Carbon. 43(14), 2902–2906 (2005)

Shen, S.: Prediction for coefficient of thermal expansion of ceramic matrix composites based on XCT Technology[D]. Nanjing University of Aeronautics and Astronautics (2017)

Acknowledgements

This work was supported by the National Basic Research Program of China, the National Natural Science Foundation of China [grant number 51675266]; the Aeronautical Science Foundation of China [grant number 2014ZB52024]; the Postgraduate Research & Practice Innovation Program of Jiangsu Province [grant number KYCX18_0314]; the Fundamental Research Funds for the Central Universities [grant number NJ20160038]; and the Jiangsu Province Key Laboratory of Aerospace Power System [grant number CEPE2019004] are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Sun, Z., Chen, P. et al. Modeling Thermal Expansion Behavior of 2.5 D C/SiC Composites in Air Oxidizing Environments between 400 °C and 800 °C. Appl Compos Mater 27, 861–875 (2020). https://doi.org/10.1007/s10443-019-09792-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09792-4