Abstract

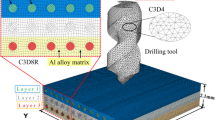

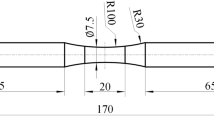

This paper reports deformation and damage evolutions of three-dimensional (3-D) braided composite with different braiding angles under multiple impact compression along longitudinal direction. Braided composites with braiding angle of 15°, 26° and 37° have been prepared for the compression tests. The impact compression test was conducted on a split Hopkison pressure bar (SHPB) along longitudinal direction. A high-speed camera was used to record damage development. A meso-scale finite element model has been established to simulate damage processes. The results show that the damage of composites occurs mainly in the first three impacts. For the 15° sample, damage of yarns and interface dominates the failure mechanisms at the first impact. For the 26° and 37° samples, the resin fracture and interface de-bonding lead to compressive failure at the first impact. Breakage and dislocation of yarns occurred for 15° sample during the subsequent two impacts, whereas it still keeps good structural integrity for 26° and 37° samples. The angle between adjacent yarns increased for the 26° sample and the yarns just tightened each other for 37° sample. Ductile damage is the primary damage mode for both yarns and resin during the multiple impacts.

Similar content being viewed by others

References

Wang, Y., Gao, X., Zhang, L., Wu, X., Wang, Q., Luo, C., Wu, G.: Synthesis of Ti3C2/Fe3O4/PANI hierarchical architecture composite as an efficient wide-band electromagnetic absorber. Appl. Surf. Sci. 480, 830–838 (2019)

Wang, Y., Zhang, W., Wu, X., Luo, C., Wang, Q., Li, J., Hu, L.: Conducting polymer coated metal-organic framework nanoparticles: facile synthesis and enhanced electromagnetic absorption properties. Synth. Met. 228, 18–24 (2017)

Zhang, H., Wang, B., Feng, A., Zhang, N., Jia, Z., Huang, Z., Liu, X., Wu, G.: Mesoporous carbon hollow microspheres with tunable pore size and shell thickness as efficient electromagnetic wave absorbers. Compos. Part B. 167, 690–699 (2019)

Wang, J., Cai, K., Yin, J., Shen, S.: Thermoelectric properties of the PEDOT/SWCNT composite films prepared by a vapor phase polymerization. Synth. Met. 224, 27–32 (2017)

Li, J., Ma, J., Chen, S., He, J., Huang, Y.: Characterization of calcium alginate/ deacetylated konjac glucomannan blend films prepared by Ca2+ crosslinking and deacetylation. Food Hydrocoll. 82, 363–369 (2018)

Feng, A., Wu, G., Wang, Y., Pan, C.: Synthesis, preparation and mechanical property of wood Fiber-reinforced poly(vinyl chloride) composites. J. Nanosci. Nanotechnol. 17(6), 3859–3863 (2017)

Kim, B.S., Hwang, B.S., Lee, S.K., Jun, E.J.: Development and trend of advanced polymer composites as structural materials in Korea. Adv. Perform. Mater. 5(4), 353–361 (1998)

Ahmad, F., Choi, H.S., Park, M.K.: A review: natural Fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 300(1), 10–24 (2015)

Sköck-Hartmann B, Gries T. Automotive applications of non-crimp fabric composites. 2011:461–480

McGregor, C., Vaziri, R., Poursartip, A., Xiao, X.: Axial crushing of triaxially braided composite tubes at quasi-static and dynamic rates. Compos. Struct. 157, 197–206 (2016)

Li, Y., Gan, X., Gu, B., Sun, B.: Dynamic responses and damage evolutions of four-step three-dimensional braided composites subjected to high strain rate punch shear loading. J. Compos. Mater. 50(12), 1635–1650 (2015)

Sun, B., Hu, H., Gu, B.: Compressive behavior of multi-axial multi-layer warp knitted (MMWK) fabric composite at various strain rates. Compos. Struct. 78(1), 84–90 (2007)

Liu, L., Luo, G., Chen, W., Zhao, Z., Huang, X.: Dynamic behavior and damage mechanism of 3D braided composite fan blade under bird impact. International J Aerospace Engineering. 2018, 1–16 (2018)

Zhao, Z., Liu, L., Chen, W., Huang, X.: Dynamic compressive behavior in different loading directions of 3D braided composites with different braiding angle. Latin American J Solids and Structures. 15(9), (2018)

Zhang, W., Gu, B., Sun, B.: Transverse impact behaviors of 3D braided composites T-beam at elevated temperatures. J. Compos. Mater. 50(28), 3961–3971 (2016)

Sun, B., Zhang, Y., Gu, B.: Low-velocity impact response and finite element analysis of four-step 3-D braided composites. Appl. Compos. Mater. 20(4), 397–413 (2012)

McGregor, C., Vaziri, R., Xiao, X.: Finite element modelling of the progressive crushing of braided composite tubes under axial impact. International J Impact Engineering. 37(6), 662–672 (2010)

Zhou, H., Li, C., Zhang, L., Crawford, B., Milani, A.S., Ko, F.K.: Micro-XCT analysis of damage mechanisms in 3D circular braided composite tubes under transverse impact. Compos. Sci. Technol. 155, 91–99 (2018)

Zhang, Y., Wang, P., Guo, C.: Energy absorption behaviors of 3D braided composites under impact loadings with frequency domain analysis. Polym. Compos. 37(5), 1620–1627 (2016)

Li, Y., Sun, B., Gu, B.: Impact shear damage characterizations of 3D braided composite with X-ray micro-computed tomography and numerical methodologies. Compos. Struct. 176, 43–54 (2017)

Lai, J., Yang, H., Wang, H., Zheng, X., Wang, Q.: Penetration experiments and simulation of three-layer functionally graded cementitious composite subjected to multiple projectile impacts. Constr. Build. Mater. 196, 499–511 (2019)

Wu, J., Liu, X., Zhou, H., Li, L., Liu, Z.: Experimental and numerical study on soft-hard-soft (SHS) cement based composite system under multiple impact loads. Mater. Des. 139, 234–257 (2018)

Li, Q., Zhao, X., Xu, S., Leung, C.K.Y., Wang, B.: Multiple impact resistance of hybrid Fiber ultrahigh toughness cementitious composites with different degrees of initial damage. J. Mater. Civ. Eng. 31(2), 04018368 (2019)

Zhou, H., Hu, D., Gu, B., Sun, B.: Transverse impact performance and finite element analysis of three dimensional braided composite tubes with different braiding layers. Compos. Struct. 168, 345–359 (2017)

Gao, X., Sun, B., Gu, B.: Damage mechanisms of 3-D rectangular braided composite under multiple impact compressions. Aerosp. Sci. Technol. 82-83, 46–60 (2018)

Mallick PK. Fiber-Reinforced Composites: Materials, Manufacturing, and Design: CRC press; 2007

Wan, F., Liu, R., Wang, Y., Sun, G., Cao, Y., Zhang, C.: Microstructure characterization and compressive performance of 3D needle-punched C/C–SiC composites fabricated by gaseous silicon infiltration. Ceram. Int. 45(6), 6897–6905 (2019)

Luan, K., Liu, J., Sun, B., Zhang, W., Hu, J., Fang, X., Ming, C., Song, E.: High strain rate compressive response of the Cf/SiC composite. Ceram. Int. 45(6), 6812–6818 (2019)

Zhang, F., Wan, Y., Gu, B., Sun, B.: Impact compressive behavior and failure modes of four-step three-dimensional braided composites-based meso-structure model. International J Damage Mechanics. 24(6), 805–827 (2015)

Kolsky, H.: An investigation of the mechanical properties of materials at very high rates of loading. Proceedings of the Physical Society Section B. 62(11), 676–700 (1949)

Gao X, Siddique A, Sun B, Gu B. Effect of braiding angle on dynamic mechanical properties of 3-D braided rectangular composites under multiple impact compressions. J. Compos. Mater. 2018:002199831881292

Li, D.S., Li, J.L., Chen, L., Lu, Z.X., Fang, D.N.: Finite element analysis of mechanical properties of 3D four-directional rectangular braided composites part 1: microgeometry and 3D finite element model. Appl. Compos. Mater. 17(4), 373–387 (2010)

Hu, M., Zhang, J., Sun, B., Gu, B.: Finite element modeling of multiple transverse impact damage behaviors of 3-D braided composite beams at microstructure level. Int. J. Mech. Sci. 148, 730–744 (2018)

Benzeggagh, M.L., Kenane, M.: Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 56(4), 439–449 (1996)

Huang, Z.M.: A unified micromechanical model for the mechanical properties of two constituent composite materials. Part IV: rubber-elastic behavior. J. Thermoplast. Compos. Mater. 13(2), 119–139 (2000)

Zhang, M., Sun, B., Gu, B.: Meso-structure ageing mechanism of 3-D braided composite's compressive behaviors under accelerated thermo-oxidative ageing environment. Mech. Mater. 115, 47–63 (2017)

Gideon, R.K., Zhou, H., Li, Y., Sun, B., Gu, B.: Quasi-static compression and compression–compression fatigue characteristics of 3D braided carbon/epoxy tube. J Textile Institute. 107(7), 938–948 (2015)

Acknowledgements

The authors acknowledge the financial supports from the Chang Jiang Scholars Program and National Science Foundation of China (Grant Number 51875099 and 51675095).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Siddique, A., Sun, B. et al. Influence of Braiding Angle on Multiple Impact Damages of 3-D Braided Composite along Longitudinal Direction. Appl Compos Mater 26, 1261–1280 (2019). https://doi.org/10.1007/s10443-019-09779-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09779-1