Abstract

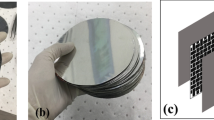

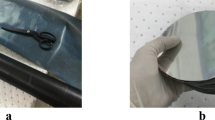

Glass-reinforced aluminum laminate (GLARE) is a new class of fiber metal laminates (FMLs) which has the advantages such as high tensile strength, outstanding fatigue, impact resistance, and excellent corrosion properties. GLARE has been extensively applied in advanced aerospace and automobile industries. However, the deformation behavior of the glass fiber during forming must be studied to the benefits of the good-quality part we form. In this research, we focus on the effect of fiber layer orientation on the GLARE laminate formability in stamp forming process. Experimental and numerical analysis of stamping a hemisphere part in different fiber orientation is investigated. The results indicate that unidirectional and multi-directional fiber in the middle layer make a significant effect on the thinning and also surface forming quality of the three layer sheet. Furthermore, the stress-strain distribution of the aluminum alloy and the unique anisotropic property of the fiber layer exhibit that fiber layer orientation can also affect the forming depths as well as the fracture modes of the laminate. According to the obtained results, it is revealed that multi-directional fiber layers are a good alternative compared to the unidirectional fibers especially when a better formability is the purpose.

Similar content being viewed by others

References

Vlot A, Vogelesang LB, de Vries TJ. Fiber metal laminates for high capacity aircraft. 30th International SAMPE technical conference pp. 456–70 (1998)

Asundi, A., Choi, A.Y.N.: Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 63, 384–394 (1997)

Reyes, G., Kang, H.: Mechanical behavior of lightweight thermoplastic fiber–metal laminates. J. Mater. Process. Technol. 186, 284–290 (2007)

Sinmazçelik, T., Avcu, E., Bora, M.Ö., Çoban, O.: A review: Fiber metal laminates, background, bonding types and applied test methods. Mater. Des. 32, 3671–3685 (2011)

Vogelesang, L.B., Gunnink, J.W.: ARALL: A materials challenge for the next generation of aircraft. J. Mater. Des. 7, 287–300 (1986)

Bucci, R.J., Mueller, L.N.: ARALL@Laminates. J. Treatise Mater. Sci. Technol. 31, 295–322 (1989)

Li, E., Johnson, W.S.: An investigation into the Fatigue of Hybrid Titanium Composite laminate. J. Compos. Technol. 20(1), 3–12 (1998)

Burianek, D.A., Spearing, S.M.: Delamination Growth Face Sheet Seams in Cross-Ply Titanium/Graphite Hybrid Laminates. Compos. Sci. Technol. 61, 261–269 (2000)

Burianek, D.A., Giannakopoulos, A.E., Spearing, S.M.: Modeling of facesheet crack growth in titanium–graphite hybrid laminates. Int. J. Eng. Fract. Mech. 70, 775–812 (2003)

Vermeeren, C.A.J.R.: A Historical Overview of the Development of Fiber-metal Laminate. J. Compos. Mater. 10, 189–205 (2003)

Wu, G., Yang, J.-M.: The Mechanical Behavior of GLARE Laminates for Aircraft Structures. J. Fail. Struct. Mater. 72–79 (2005)

Botelho, E.C., Silva, R.A.: A Review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater. Res. 9(3), 247–256 (2006)

Park, S.Y., Choi, W.J., Choi, H.S.: A comparative study on the properties of GLARE laminates cured by autoclave and autoclave consolidation followed by oven postcuring. Int. J. Adv. Manuf. Technol. 49, 605–613 (2010)

Dmitriev O, Mischenko. Optimization of curing cycles for thick-wall products of the polymeric composite materials. INTECH Open Access Publisher ISBN 978–953–307-150-3, pp. 141–160 S (2011)

Kumar, K.V., Safiullah, M.: Ahmad ANK Root cause analysis of heating rate deviations in autoclave curing of CFRP structures. Int. J. Innov. Res. Stud. 2(5), 369–378 (2013)

Sinke J.: Forming technology for composite/metal hybrids. Compos. Form. Technol. 197–219 (2007). doi:10.1533/9781845692537.197

Sokolova, O., Carrado, A., Palkowski, H.: Metal–polymer–metal sandwiches with local metal reinforcements: A study on formability by deep drawing and bending. Compos. Struct. 94, 1–7 (2011)

Yanagimoto, J., Ikeuchi, K.: Sheet forming process of carbon fiber reinforced plastics for lightweight parts. J CIRP Ann. Manuf. Technol. 61(1), 247–250 (2012)

Mosse, L., Compston, P., Cantwell, W., Cardew-Hall, M., Kalyanasundaram, S.: Effect of process temperature on the formability of fiber–metal laminates. Compos. Part. A36, 1158–1166 (2005)

Mossea, L., Compston, P., Cantwell, W.J., Cardew-Hall, M., Kalyanasundaram, S.: Stamp forming of polypropylene based fiber–metal laminates: The effect of process variables on formability. J. Mater. Process. Technol. 172, 163–168 (2006)

Sokolova, O.A., Kuhn, M.: Deep drawing properties of lightweight steel/polymer/steel sandwich composites. Int. J. Mech. Eng. 12, 105–112 (2012)

Huang, Y., Liu, J.Z., Huang, X.: Delamination and fatigue crack growth behavior in Fiber Metal Laminates (Glare) under single overloads. Int. J. Fatigue. 78, 53–60 (2014)

N Ghamarian, M. A. Azmah Hanim. Effect of fiber orientation on the mechanical properties of laminated polymer composites. Int. J. Mater. Sci. Eng. pp. 100–116 (2016)

Bienias, J., Dadej, K.: Interlaminar fracture toughness of glass and carbon reinforced multidirectional fiber metal laminates. Int. J. Eng. Fract. Mech. 175, 127–145 (2017)

Acknowledgements

The authors greatly acknowledge the financial support from National Science and Technology Major Project with Grant No.2014ZX04002041 and National Science Foundation of China with Grant No.51675029.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, S., Lang, L., Sherkatghanad, E. et al. Investigation into the Fiber Orientation Effect on the Formability of GLARE Materials in the Stamp Forming Process. Appl Compos Mater 25, 255–267 (2018). https://doi.org/10.1007/s10443-017-9615-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9615-7