Abstract

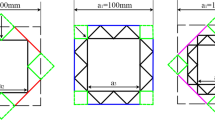

To predict the crashworthy composite corrugated plate, different single and stacked shell models are evaluated and compared, and a stacked shell progressive damage model combined with continuum damage mechanics is proposed and investigated. To simulate and predict the failure behavior, both of the intra- and inter- laminar failure behavior are considered. The tiebreak contact method, 1D spot weld element and cohesive element are adopted in stacked shell model, and a surface-based cohesive behavior is used to capture delamination in the proposed model. The impact load and failure behavior of purposed and conventional progressive damage models are demonstrated. Results show that the single shell could simulate the impact load curve without the delamination simulation ability. The general stacked shell model could simulate the interlaminar failure behavior. The improved stacked shell model with continuum damage mechanics and cohesive element not only agree well with the impact load, but also capture the fiber, matrix debonding, and interlaminar failure of composite structure.

Similar content being viewed by others

References

Liu, X.C., Guo, J., Bai, C.Y., Sun, X.S., Mou, R.K.: Drop test and crash simulation of a civil airplane fuselage section. Chin. J. Aeronaut. 28(2), 447–456 (2015)

Tay, Y.Y., Bhonge, P.S., Lankarani, H.M.: Crash simulations of aircraft fuselage section in water impact and comparison with solid surface. Int. J. Crashworthiness. 20(5), 464–482 (2015)

Ren, Y.R., Xiang, J.W.: A comparative study of the crashworthiness of civil aircraft with different strut configurations. Int. J. Crashworthiness. 15(3), 321–330 (2010)

Li, D.C., Wu, Y.N., Ronch, A.D., Xiang, J.W.: Energy harvesting by means of flow-induced vibrations on aerospace vehicles. Prog. Aerosp. Sci. 86, 28–62 (2016)

Guo, S.J., Li, D.C., Zhang, X., Xiang, J.W.: Buckling and post-buckling of a composite C-section with cutout and flange reinforcement. Compos. Part B. 60(3), 119–124 (2014)

El Kadi, H.: Predicting the crushing behavior of axially loaded elliptical composite tubes using artificial neural networks. Appl. Compos. Mater. 15, 273–285 (2008)

Zangani, D., Robinson, M., Gibson, A.G.: Energy absorption characteristics of web-Core sandwich composite panels subjected to drop-weight impact. Appl. Compos. Mater. 15, 139–156 (2008)

Kumar, D., Roy, R., Kweon, J.-H., Choi, J.-h.: Numerical modeling of combined matrix cracking and delamination in composite laminates using cohesive elements. Appl. Compos. Mater. 108, 570–580 (2016)

McConnell, J.R., Hong, S.: Design of cellular composite sandwich panels for maximum blast resistance via energy absorption. Appl. Compos. Mater. 23, 375–396 (2016)

David, M., Johnson, A.F., Voggenreiter, H.: Analysis of crushing response of composite crashworthy structures. Appl. Compos. Mater. 20, 773–787 (2013)

Jager, S., Pickett, A., Middendorf, P.: A discrete model for simulation of composites plate impact including coupled intra- and inter-ply failure. Appl. Compos. Mater. 23, 179–195 (2016)

Yang, L., Li, Z., Sun, T., Wu, Z.: Effects of gear-shape Fibre on the transverse mechanical properties of unidirectional composites: virtual material design by computational micromechanics. Appl. Compos. Mater., (2017). doi:10.1007/s10443-016-9580-6

Han, G., Guan, Z., Li, Z., Shanyi, D.: Microscopic progressive damage simulation and scale-span analysis of cross-ply laminate based on the elastic–plastic theory. Appl. Compos. Mater. 22, 1–12 (2015)

Ji, Z., Guan, Z., Li, Z.: A Progressive damage model for predicting permanent indentation and impact damage in composite laminates. Appl. Compos. Mater., (2016). doi:10.1007/s10443-016-9572-6

Shi, Q.H., Dai, D., Cao, Z.H.: Tensile failure strength analysis and experimental confirmation of stitch reinforced composite of T-stiffened structure. Polym. Polym. Compos. 20(3), 307–311 (2012)

Pearce, G.M.K., Johnson, A.F., Hellier, A.K.: A stacked-Shell finite element approach for modelling a dynamically loaded composite bolted joint under in-plane bearing loads. Appl. Compos. Mater. 20, 1025–1039 (2013)

Liu, P.F., Yang, Y.H., Gu, Z.P., Zheng, J.Y.: Finite element analysis of progressive failure and strain localization of carbon fiber/epoxy composite laminates by ABAQUS. Appl. Compos. Mater. 22, 711–731 (2015)

Malusare, K.A., Fertig, R.S.: Composite interaction energy and constituent average stresses for predicting composite failure. AIAA J. 52(11), 2455–2461 (2014)

Wiggenraad, J.F.M., Michielsen, A.P.J., Santoro, D., Le, P.F., Kindervater, C.M., Beltran, F.: Development of a crashworthy composite fuselage structure for a commuter aircraft. Nationall Lucht-en Ruimtevaart laboratorium (NLR), NLR-TP -99532, (1999)

Vicecte, J.L.S., Beltran, F., Martinez, F.: Simulation of Impact on Composite Fuselage Structures, pp. 1–10. European Congress on Computational Methods in Applied Sciences and Engineering, Barcelona (2000)

Ren, Y.R., Xiang, J.W., Zheng, J.Q., Luo, Z.P.: Crashworthiness analysis of aircraft fuselage with sine-wave beam structure. Chin. J. Aeronaut. 29(2), 403–410 (2016)

Feraboli, P.: Development of a corrugated test specimen for composite materials energy absorption. J. Compos. Mater. 42(3), 229–256 (2008)

Grauers, L., Olsson, R., Gutkin, R.: Energy absorption and damage mechanisms in progressive crushing of corrugated NCF laminates: Fractographic analysis. Compos. Struct. 110, 110–117 (2014)

Duan, S.Y., et al.: Investigation on structure optimization of optimization of crashworthiness of fiber reinforced polymers material[J]. Compos. Part B. 60, 471–478 (2014)

Feraboli, P., Wade, B., Deleo, F., Rassaian, M., Higgins, M., Byar, A.: LS-DYNA MAT54 modeling of the axial crushing of a composite tape sinusoidal specimen. Compos. Part A. 42, 1809–1825 (2011)

Sokolinsky, V.S., Indermuehle, K.C., Hurtado, J.A.: Numerical simulation of the crushing process of a composite corrugated plate. Compos. Part A. 42, 1119–1126 (2011)

Acknowledgements

This research is co-supported by the National Natural Science Foundation of China (No. 11402011) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, Y., Jiang, H., Ji, W. et al. Improvement of Progressive Damage Model to Predicting Crashworthy Composite Corrugated Plate. Appl Compos Mater 25, 45–66 (2018). https://doi.org/10.1007/s10443-017-9610-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9610-z