Abstract

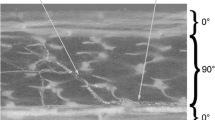

In this paper, the Inter-Fiber Fracture (IFF) criterion of Puck failure theory based on the eXtended Finite Element Method (XFEM) was implemented in ABAQUS code to predict the intra-laminar crack initiation of unidirectional (UD) composite laminate. The transverse crack path in the matrix can be simulated accurately by the presented method. After the crack initiation, the propagation of the crack is simulated by Cohesive Zoom Model (CZM), in which the displacement discontinuities and stress concentration caused by matrix crack is introduced into the finite element (FE) model. Combined with the usage of the enriched element interface, which can be used to simulate the inter-laminar delamination crack, the Low Velocity Impact (LVI) induced damage of UD composite laminate beam with a typical stacking of composite laminates [05/903]S is studied. A complete crack initiation and propagation process was simulated and the numerical results obtained by the XFEM are consistent with the experimental results.

Similar content being viewed by others

References

Rechak, S., Sun, C.T.: Optimal Use of Adhesive Layers in Reducing Impact Damage in Composite Laminates, pp. 18–31. Springer, Dordrecht (1987)

Zhang, J., Zhang, X.: Simulating low-velocity impact induced delamination in composites by a quasi-static load model with surface-based cohesive contact. Compos. Struct. 125, 51–57 (2015)

Gigliotti, L., Pinho, S.T.: Multiple length/time-scale simulation of localized damage in composite structures using a mesh superposition technique. Compos. Struct. 121, 395–405 (2015)

Hashin, Z.: Failure criteria for unidirectional fiber composites. J. Appl. Mech. 47(2), 329–334 (1980)

Zinoviev, P.A., Lebedeva, O.V., Tairova, L.P.: A coupled analysis of experimental and theoretical results on the deformation and failure of composite laminates under a state of plane stress. Compos. Sci. Technol. 62(12–13), 1711–1723 (2002)

Bogetti, T.A., Hoppel, C.P.R., Harik, V.M., Newill, J.F., Burns, B.P.: Predicting the nonlinear response and progressive failure of composite laminates. Compos. Sci. Technol. 64(3–4), 329–342 (2004)

Puck, A., Schürmann, H.: Failure analysis of FRP laminates by means of physically based phenomenological models. Compos. Sci. Technol. 62(7), 1633–1662 (2002)

Cuntze, R.G., Freund, A.: The predictive capability of failure mode concept-based strength criteria for multidirectional laminates. Compos. Sci. Technol. 64(3–4), 343–377 (2004)

Liu, K.-S., Tsai, S.W.: A progressive quadratic failure criterion for a laminate. Compos. Sci. Technol. 58(7), 1023–1032 (1998)

He, W., Guan, Z., Li, X., Liu, D.: Prediction of permanent indentation due to impact on laminated composites based on an elasto-plastic model incorporating fiber failure. Compos. Struct. 96, 232–242 (2013)

Wiegand, J., Petrinic, N., Elliott, B.: An algorithm for determination of the fracture angle for the three-dimensional Puck Matrix failure criterion for UD composites. Compos. Sci. Technol. 68(12), 2511–2517 (2008)

Schirmaier, F.J., Weiland, J., Kärger, L., Henning, F.: A new efficient and reliable algorithm to determine the fracture angle for Puck’s 3D matrix failure criterion for UD composites. Compos. Sci. Technol. 100, 19–25 (2014)

Shi, Y., Swait, T., Soutis, C.: Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 94(9), 2902–2913 (2012)

Tan, W., Falzon, B.G., Chiu, L.N.S., Price, M.: Predicting low velocity impact damage and compression-after-impact (CAI) behaviour of composite laminates. Compos Part A-Appl Sci Manuf. 71, 212–226 (2015)

Belytschko, T., Black, T.: Elastic crack growth in finite elements with minimal remeshing. Intl J Numer Meth Eng. 45(5), 601–620 (1999)

Moes, N., Belytschko, T.: Extended finite element method for cohesive crack growth. Eng. Fract. Mech. 69(7), 813–833 (2002)

Alberti, M.G., Enfedaque, A., Gálvez, J.C., Reyes, E.: Numerical modelling of the fracture of polyolefin fibre reinforced concrete by using a cohesive fracture approach. Compos Part B-Eng. 111, 200–210 (2017)

Hu, X.F., Chen, B.Y., Tirvaudey, M., Tan, V.B.C., Tay, T.E.: Integrated XFEM-CE analysis of delamination migration in multi-directional composite laminates. Compos Part A-Appl Sci Manuf. 90, 161–173 (2016)

Vigueras, G., Sket, F., Samaniego, C., Wu, L., Noels, L., Tjahjanto, D., et al.: An XFEM/CZM implementation for massively parallel simulations of composites fracture. Compos. Struct. 125, 542–557 (2015)

Zhao, L., Zhi, J., Zhang, J., Liu, Z., Hu, N.: XFEM simulation of delamination in composite laminates. Compos Part A-Appl Sci Manuf. 80, 61–71 (2016)

Curiel Sosa, J.L., Karapurath, N.: Delamination modelling of GLARE using the extended finite element method. Compos. Sci. Technol. 72(7), 788–791 (2012)

Puck, A., Schürmann, H.: Failure analysis of FRP laminatrs by means of physically based phenomenological models. Compos. Sci. Technol. 58(7), 1045–1067 (1998)

Zhao, L., Gong, Y., Zhang, J., Chen, Y., Fei, B.: Simulation of delamination growth in multidirectional laminates under mode I and mixed mode I/II loadings using cohesive elements. Compos. Struct. 116, 509–522 (2014)

Benzeggagh, M.L., Kenane, M.: Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 56(4), 439–449 (1996)

ABAQUS. ABAQUS 6.13 Documentation. Dassault systems

Soden, P.D., Hinton, M.J., Kaddour, A.S.: Biaxial test results for strength and deformation of a range of E-glass and carbon fibre reinforced composite laminates: failure exercise benchmark data. Compos. Sci. Technol. 62(12–13), 1489–1514 (2002)

Aragone’s, D.: Fracture micromechanisms in C/epoxy composites under transverse compression. Master thesis, Universidad Polite ´cnica de Madrid (2007)

Topac, O.T., Gozluklu, B., Gurses, E., Coker, D.: Experimental and computational study of the damage process in CFRP composite beams under low-velocity impact. Compos Part A-Appl Sci Manuf. 92, 167–182 (2017)

Shi, Y., Soutis, C.: Modelling transverse matrix cracking and splitting of cross-ply composite laminates under four point bending. Theor. Appl. Fract. Mech. 83, 73–81 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, W., Guan, Z. & Li, Z. Simulation of Low Velocity Impact Induced Inter- and Intra-Laminar Damage of Composite Beams Based on XFEM. Appl Compos Mater 24, 1459–1477 (2017). https://doi.org/10.1007/s10443-017-9598-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9598-4