Abstract

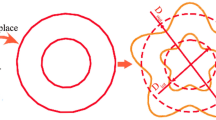

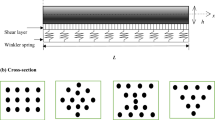

Tearing behaviors of the envelope material is important for the stratospheric airship because it directly decides the service life of the airship. Uniaxial tensile tests of the specimens with different initial damage were performed to study the tear propagation properties of a new kind of envelope material for the stratospheric airship. A Matlab program was developed to simulate the mechanical properties in the tensile process. The interaction forces between warp and weft yarns were considered, and the yarns in the transition region between deformed region and non- deformed region were assumed as hinges in the simulation. It is discovered that the interaction factor, which represents interaction force between different components of the material, and the frictional coefficient between warp and weft yarns are the crucial factors for the tensile curves of the material. The tear strength and the damage mode of the envelope material are determined by the number of the cutoff yarns and the declination of the initial cracks, respectively.

Similar content being viewed by others

References

Colozza, A., Dolce, J. L.: High-altitude, long-endurance airships for coastal surveillance. NASA Technical Report, NASA/TM-2005-213427 (2005).

Colozza, A., Dolce, J.: Initial feasibility assessment of a high altitude long endurance airship. (2003).

Khoury, G.A.: Airship technology, vol. 10. Cambridge University Press, (2012).

Komatsu, K., Sano, M., Kakuta, Y.: Development of high-specific-strength envelope materials. (2003). doi:10.2514/6.2003-6765

Chen, J., Chen, W., Zhao, B., Yao, B.: Mechanical responses and damage morphology of laminated fabrics with a central slit under uniaxial tension: a comparison between analytical and experimental results. Construct. Build Mater. 101, 488–502 (2015). doi:10.1016/j.conbuildmat.2015.10.134

Maekawa, S., Shibasaki, K., Kurose, T., Maeda, T., Sasaki, Y., Yoshino, T.: Tear propagation of a high-performance airship envelope material. J. Aircr. 45(5), 1546–1553 (2008). doi:10.2514/1.32264

Meng, J., Lv, M., Tan, D., Li, P.: Mechanical properties of woven fabric composite for stratospheric airship envelope based on stochastic simulation. J. Reinf. Plast. Compos. 0731684416652947 (2016).

Meng, J., Lv, M., Qu, Z., Li, P.: Mechanical properties and strength criteria of fabric membrane for the stratospheric airship envelope. Appl. Compos. Mater. 1–19 (2016).

Meng, J., Cao, S., Qu, Z., Li, J., Lv, M.: Thermoelasticity of a fabric membrane composite for the stratospheric airship envelope based on multiscale models. Appl. Compos. Mater. 1–12 (2016).

Turl, L.: The measurement of tearing strength of textile fabrics. Text. Res. J. 26(3), 169–176 (1956)

Lagerquist, D., Keen, L.: Structural design of a high-altitude superpressure powered aerostat. (1975). doi:10.2514/6.1975-933

Mollaert, M., Forster, B.: European design guide for tensile surface structures. Tensinet. Union Europea (2004).

Longbin, L., Mingyun, L., Houdi, X.: Tear strength characteristics of laminated envelope composites based on single edge notched film experiment. Eng. Fract. Mech. 127, 21–30 (2014). doi:10.1016/j.engfracmech.2014.04.026

Jiangbo, B., Xiong, J., Cheng, X.: Tear resistance of orthogonal Kevlar-PWF-reinforced TPU film. Chin. J. Aeronaut. 24(1), 113–118 (2011)

Zhong, W., Pan, N., Lukas, D.: Stochastic modelling of tear behaviour of coated fabrics. Model. Simul. Mater. Sci. Eng. 12(2), 293–309 (2004). doi:10.1088/0965-0393/12/2/010

Liu, D.X., Jia, Z., Hu, J., Guo, P.F., Ma, Y.P.: Study on tear propagation of a fabric laminate in biaxial stress. Adv. Mat. Res. 217–218, 147–151 (2011). doi:10.4028/www.scientific.net/AMR.217-218.147

Cox, H.: The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 3(3), 72 (1952)

Zhong, W., Pan, N.: A computer simulation of single fiber pull out process in a composite. J. Compos. Mater. 37(21), 1951–1969 (2003). doi:10.1177/002199803036267

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, J., Li, P., Ma, G. et al. Tearing Behaviors of Flexible Fiber-Reinforced Composites for the Stratospheric Airship Envelope. Appl Compos Mater 24, 735–749 (2017). https://doi.org/10.1007/s10443-016-9539-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9539-7