Abstract

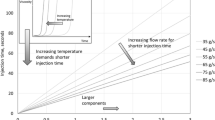

Liquid Resin Infusion (LRI) processes including VARI and VARTM have received increasing attention in recent years, particularly for infusion of large parts, or for low volume production. This method avoids the need for costly matched metal tooling as used in Resin Transfer Moulding (RTM) and can provide fast infusion if used in combination with flow media. Full material characterisation for LRI analysis requires models for three dimensional fabric permeability as a function of fibre volume content, fabric through-thickness compliance as a function of resin pressure, flow media permeability and resin viscosity.

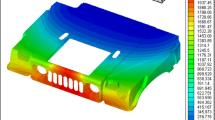

The characterisation of fabric relaxation during infusion is usually determined from cyclic compaction tests on saturated fabrics. This work presents an alternative method to determine the compressibility by using LRI flow simulation and fitting a model to experimental thickness measurements during LRI. The flow media is usually assumed to have isotropic permeability, but this work shows greater simulation accuracy from combining the flow media with separation plies as a combined orthotropic material. The permeability of this combined media can also be determined by fitting the model with simulation to LRI flow measurements. The constitutive models and the finite element solution were validated by simulation of the infusion of a complex aerospace demonstrator part.

Similar content being viewed by others

References

Rudd, C., Long, A., Kendall, K., Mangin, G.: Liquid moulding technologies. Woodhead Publishing, Cambridge (1997)

Advani, S., Sozer, E.: Process modeling in composites manufacturing, CRC Press, (2010)

Darcy, H.: Les fontaines publiques de la Ville de Dijon. Dalmont, Paris (1856)

Correia, N.C., Robitaille, F., Long, A.C., Rudd, C.D., Šimaček, P., Advani, S.G.: Analysis of the vacuum infusion moulding process: I. Anal formulation Composites Part A 36, 1645–1656 (2005)

Trochu, F., Ruiz, E., Achim, V., Soukane, S.: Advanced numerical simulation of liquid composite molding for process analysis and optimization. Compos. Part A 37, 890–902 (2006)

Andersson, H., Lundstrom, T., Langhans, N.: Computational fluid dynamics applied to the vacuum infusion process. Polym. Compos. 26(2), 231–239 (2005)

Bruschke, M., Advani, S.: A finite element/control volume approach to mold filling in anisotropic porous media. Polym. Compos. 6(11), 398–405 (1990)

LIMS, http://www.ccm.udel.edu/Pubs/techbriefs/102.html. University of Delaware, USA (2013)

RTM-WORX. http://www.polyworx.com/pwx/ POLYWORX, Netherlands (2013)

PAM-RTM, Paris, France: ESI Group

Robinson, M.J., Kosmatka, J.B.: Vacuum assisted resin transfer molding simulation for thick laminate structures. In: proceedings of 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials. Schaumburg, IL, (April 2008).

Kessels, J.F.A., Jonker, A.S., Akkerman, R.: Fully 2.5D flow modeling of resin infusion under flexible tooling using unstructures meshes and wet and dry compaction properties. Composites: Part A, 38 (1), 51–60 (2007)

Yenilmez, B., Sozer, E.M.: Compaction of e-glass fabric preforms in the vacuum infusion process. A Characterisation experiments. Composites Part A 40, 499–510 (2009)

Yenilmez, B., Senan, M., Sozer, E.M.: Variation of part thickness and compaction pressure in vacuum infusion process. Compos. Sci. Technol. 69(11–12), 1710–1719 (2009)

Gocke, A., Chora, M., Advani, S.G., Walsh, S.M.: Permeability estimation algorithm to simultaneously characterize the distribution media and the fabric preform in vacuum assisted resin transfer molding process. Compos. Sci. Technol. 65, 2129–2139 (2005)

Momentive Specialty Chemicals Inc., EPIKOTE™ Resin MGS® LR 235 and EPIKURE™ Curing Agent MGS® LH 233–238, Technical Data Sheet, Momentive Specialty Chemicals Inc., http://www.hexion.com

George, A.: Optimization of Resin Infusion Processing for Composite Materials: Simulation and Characterization Strategies. Universität Stuttgart, PhD Thesis (2011)

Arbter, R., et al.: Experimental determination of the permeability of textiles: a benchmark exercise. Compos. Part A 42, 1157–1168 (2011)

Nedanov, P., Advani, S.: A method to determine 3D permeability of fibrous reinforcements. J. Compos. Mater. 36, 241–254 (2002)

George, A., Pickett, A., Sirtautas, J., Drechsler, K.: Optimization of 3D wetting permeability measurements. In: proceedings of FPCM-11, Auckland (New Zealand) (July 2012)

Weitzenböck, J.R., Shenoi, R.A., Wilson, P.A.: Radial flow permeability measurement. Part A Theory. Composites Part A 30, 781–796 (1999)

Klunker, F., Ziegmann, G., Aranda, S., Liu, Y.M.: Permeability Measurement of Flow Enhancement Layers by an Indirect Measurement Technique Using Flow Simulation. In: proceedings of SEICO, Paris (France), 491–6 (Mar 31-April 2, 2008)

Robitaille, F., Gauvin, R.: Compaction of textile reinforcements for composites manufacturing III. Reorganization of the fiber network. Polym. Compos. 20(1), 48–61 (1999)

Heardman, E., Lekakou, C., Bader, M.G.: In-plane permeability of sheared fabrics. Compos. Part A 32, 933–940 (2001)

Acknowledgements

This work was partially undertaken within the CEC Framework VII project INFUCOMP (Contract 233926) and the support of the CEC is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sirtautas, J., Pickett, A.K. & George, A. Materials Characterisation and Analysis for Flow Simulation of Liquid Resin Infusion. Appl Compos Mater 22, 323–341 (2015). https://doi.org/10.1007/s10443-014-9411-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9411-6