Abstract

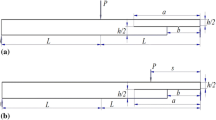

A method was proposed to test the pull-through mechanical behavior of fastener threads, which were fabricated from weave carbon/carbon (C/C) composites. The damage morphologies of the C/C fastener threads were observed through an optical microscope and high-resolution micro-CT systems. The acoustic emission (AE) technique was utilized to track the damage progression of threads during loading up to fracture in terms of AE event rate which has an exponential type profile. Finally, A 3D finite element damage evolution model of composite threads was established based on continuum damage mechanics to calculate the thread load distribution and damage progression. The relations between the pitch and the load distribution, as well as between different fabrication directions and ultimate loads, were investigated by using this model. The stress in the first thread was analyzed based on the tapered cantilever assumption. The results show that, the first thread is brittle fracture at the root where is the higher stress level region of the threads and it is the initial damage. The load distribution in C/C threads is not uniform and not improved as the value of pitch decreases. Load capacity of C/C threads is different result from the fabrication direction. Numerical results agree well with experimental results.

Similar content being viewed by others

Abbreviations

- σ :

-

Stress matrix

- ε :

-

Strain matrix

- C 0 :

-

Initial elastic matrix

- D :

-

The damages matrix

- C d :

-

Damages elastic matrix

- r :

-

Polar co-ordinate

- θ :

-

Polar co-ordinate

- ± β :

-

Thread angle

- μ :

-

Coefficient of friction between bolt and nut threads (tan φ = μ)

- w :

-

Intensity of loading per unit length of helix

- Q :

-

Axial load

- F :

-

Transverse load

- M :

-

Moment

- N :

-

Pull-through load

- b :

-

Depth of thread

- b :

-

Thread thickness at the root

- t :

-

Thickness of tapered cantilever thread

- Φ :

-

Stress function

- \( \overline{rr} \) and \( \overline{r\theta} \) :

-

Stress in polar co-ordinate

References

Krenkel, W., Heidenreich, B., Renz, R.: C/C-SiC composites for advanced friction systems [J]. Adv Eng Mater 4(7), 427–436 (2002)

C. Han, X.D. He, S.Y. Du. Oxidation and ablation of 3D carbon-carbon composite at up to 3000 °C [J]. Carbon, 95,33 (4):473–478.

Manocha, L.M.: High performance carbon–carbon composites [J]. Sad Hana 28(1–2), 349–58 (2003)

Dixon, D.G.: Ceramic matrix composite-metal brazed joints [J]. J Mater Sci 30(6), 1539–1544 (1995)

Henriksen, A.F.: The nuts and bolts of ceramic fasteners [J]. J Mach Des 8, 72–74 (2006)

Dadras, P., Ngai, T.T., Mehrotra, G.M.: Joining of carbon-carbon composites using boron and titanium disilicide interlayers [J]. J Am Ceram Soc 80(1), 125–132 (1997)

Whale, E.: Ceramic fasteners for high temperature applications [J]. Mater Technol 15(4), 276–281 (2000)

Dogigli, M., Handrick, K., Bickel, M., et al.: CMC key technologies-background, status, present and future applications, ESA SP-521 [R]. ESA, Paris (2003)

Bohrk, H., Beyermann, U.: Secure tightening of a CMC fastener for the heat shield of re-entry vehicles [J]. Compos Struct 92, 107–112 (2010)

Hui, M., Laifei, C., Qingqing, K., et al.: High-temperature tensile properties and oxidation behavior of carbon fiber reinforced silicon carbide bolts in a simulated re-entry environment [J]. Carbon 48, 3007–3013 (2010)

Sopwith, D.G.: The distribution of load in screw threads [J]. Proc Inst Mech Eng 159(1), 373–383 (1948)

Yamatoto, A. The theory and computation of threads connection. Youkendo, Tokyo, 1980:39–54

Guellali, M., Oberacker, R., Hoffmann, M.J.: Influence of the matrix microstructure on the mechanical properties of CVI infiltrated carbon fiber felts [J]. Carbon 43(9), 1954–1960 (2005)

Probstb, K.J., Besmanna, T.M., David, P.: Recent advances in forced-flow, thermal-gradient CVI for refractory composites [J]. Surf Coat Technol 120(3), 250–258 (1999)

Martin, H.J., Germain, C.: Microstructure reconstruction of fibrous C/C composites from X-ray microtomography [J]. Carbon 45, 1242–1253 (2007)

Meallister, L.E., Taverna, A.R.: A study of composition-construction variation in 3D carbon/carbon composites. Int Conf Compos Mater 1, 307–326 (1975)

Juhi Kushwaha, V.: Pawan Kumar, and K.H. Sinnur. Development and evaluation of carbon-carbon threaded fasteners for high temperature applications [J]. Def Sci J 62(5), 348–355 (2012)

Reznik, B., Gerthsen, D.: Hu¨ ttinger KJ. Macro- and nanostructure of the carbon matrix of infiltrated carbon fiber felts [J]. Carbon 39(2), 215–29 (2001)

Kenny, B., Patterson, E.A.: Load and stress distribution in screw threads [J]. Exp Mech 25(3), 208–213 (1985)

Siron, O., Chollon, G., Tsuda, H., Yamauchi, H., Maeda, H., Kosaka, K.: Micro-structural and mechanical properties of filler-added coal-tar pitch-based C/C composites: the damage and fracture process in correlation with AE waveform parameters [J]. Carbon 38(9), 1369–89 (2000)

Ni, Q.Q., Kurashiki, K., Iwamoto, M.: AE technique for identification of micro failure Modes in CFRP composites [J]. Mater Sci Res Int 7(1), 67–71 (2001)

Hashin, Z.: Failure criteria for unidirectional fiber composites [J]. J Appl Mech 47, 329–334 (1980)

Liu, S., Guan, Z., Guo, X.: etal. Edgewise compressive performance of repaired composite sandwich panels-Experiment and finite element analysis [J]. J Reinf Plast Compos 32(18), 1331–1347 (2013)

Sopwith, D.G., Sc, D., Wh, S., MI Mech, E.: The distribution of load in screw threads [J]. Proc Inst Mech Eng 159, 373–383 (1948)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guan, Z., Mu, J., Su, F. et al. Pull-Through Mechanical Behavior of Composite Fastener Threads. Appl Compos Mater 22, 251–267 (2015). https://doi.org/10.1007/s10443-014-9404-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9404-5