Abstract

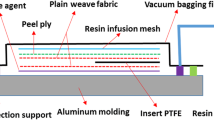

We characterize the combined Mode I and Mode III delamination fracture behavior of woven glass fiber reinforced polymer (GFRP) composite laminates at cryogenic temperatures. The eight-point bending plate (8PBP) tests were conducted at room temperature, liquid nitrogen temperature (77 K) and liquid helium temperature (4 K) using a new test fixture. A three-dimensional finite element analysis was also performed to calculate the energy release rate distribution along the delamination front, and the delamination fracture toughnesses were evaluated for various mixed-mode I/III ratios. Furthermore, the microscopic examinations of the fracture surfaces were carried out with scanning electron microscopy (SEM), and the mixed-mode I/III delamination fracture mechanisms in the woven GFRP laminates at cryogenic temperatures were assessed. The fracture properties were then correlated with the observed characteristics.

Similar content being viewed by others

References

Shindo, Y., Horiguchi, K., Wang, R., Kudo, H.: Double cantilever beam measurement and finite element analysis of cryogenic mode I interlaminar fracture toughness of glass-cloth/epoxy laminates. ASME J. Eng. Mater. Technol. 123, 191–197 (2001)

Horiguchi, K., Shindo, Y., Kudo, H., Kumagai, S.: End-notched flexure testing and analysis of mode II interlaminar fracture behavior of glass-cloth/epoxy laminates at cryogenic temperatures. J. Compos. Technol. Res. 24(4), 239–245 (2002)

Shindo, Y., Sato, T., Narita, F., Sanada, K.: Mode II interlaminar fracture and damage evaluation of GFRP woven laminates at cryogenic temperatures using the 4ENF specimen. J. Compos. Mater. 42(11), 1089–1101 (2008)

Rizov, V., Shindo, Y., Horiguchi, K., Narita, F.: Mode III interlaminar fracture behavior of glass fiber reinforced polymer woven laminates at 293 to 4 K. Appl. Compos. Mater. 13, 287–304 (2006)

Shindo, Y., Shinohe, D., Kumagai, S., Horiguchi, K.: Analysis and testing of mixed-mode interlaminar fracture behavior of glass-cloth/epoxy laminates at cryogenic temperatures. ASME J. Eng. Mater. Technol. 127, 468–475 (2005)

Shindo, Y., Takahashi, S., Takeda, T., Narita, F., Watanabe, S.: Mixed-mode interlaminar fracture and damage characterization in woven fabric-reinforced glass/epoxy composite laminates at cryogenic temperatures using the finite element and improved test methods. Eng. Fract. Mech. 75, 5101–5112 (2008)

Pereira, A.B., de Morais, A.B.: Mixed-mode I + III interlaminar fracture of carbon/epoxy laminates. Compos. Part A Appl. Sci. Manuf. 40, 518–523 (2009)

Hahn, H.T., Pandey, R.: A micromechanics model for thermoelastic properties of plain weave fabric composites. ASME J. Eng. Mater. Technol. 116, 517–523 (1994)

Shindo, Y., Miura, M., Takeda, T., Narita, F., Watanabe, S.: Piezoelectric control of delamination response in woven fabric composites under mode I loading. Acta Mech. (in press)

Miura, M., Shindo, Y., Takeda, T., Narita, F.: Effect of damage on the interlaminar shear properties of hybrid composite laminates at cryogenic temperatures. Compos. Struct. 93, 124–131 (2010)

Rybicki, E.F., Kanninen, M.F.: A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 9, 931–938 (1977)

Krueger, R.: Virtual crack closure technique: history, approach, and applications. ASME Appl. Mech. Rev. 57(2), 109–143 (2004)

Sundararaman, V., Davidson, B.D.: An unsymmetric double cantilever beam test for interfacial fracture toughness determination. Int. J. Solids Struct. 34(7), 799–817 (1997)

Sharif, F., Kortschot, M.T., Martin, R.H.: Mode III delamination using a split cantilever beam. In: Martin, R.H. (ed.) Composite Materials: Fatigue and Fracture, vol. 5, pp. 85–99. ASTM STP 1230, American Society for Testing and Materials, Philadelphia (1995)

Greenhalgh, E.S., Rogers, C., Robinson, P.: Fractographic observations on delamination growth and the subsequent migration through the laminate. Compos. Sci. Technol. 69, 2345–2351 (2009)

Lee, S.M.: Mode II delamination failure mechanisms of polymer matrix composites. J. Mater. Sci. 32, 1287–1295 (1997)

Gregory, J.R., Spearing, S.M.: Constituent and composite quasi-static and fatigue fracture experiments. Compos. Part A Appl. Sci. Manuf. 36, 665–674 (2005)

Nishijima, S., Okada, T., Honda, Y.: Evaluation of epoxy resin by positron annihilation for cryogenic use. Adv. Cryog. Eng. 40, 1137–1144 (1994)

Acknowledgement

This work was supported by Grant-in-Aid for JSPS Fellows (22·4782).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miura, M., Shindo, Y., Takeda, T. et al. Cryogenic Interlaminar Fracture Properties of Woven Glass/Epoxy Composite Laminates Under Mixed-Mode I/III Loading Conditions. Appl Compos Mater 20, 587–599 (2013). https://doi.org/10.1007/s10443-012-9290-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-012-9290-7