Abstract

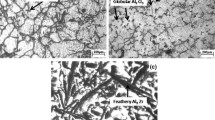

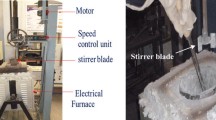

Owing to the brittle reinforced phase are introduced into ductile matrix phase, metal–intermetallic interpenetrating composites exhibit various types of wear mechanism such as adhesive, abrasive, and fatigue wear. In present work, the wear model has been proposed according to the mixing rule. Many factors such as special topology structure characteristic of reinforcement and elastic module were discussed in this model. The model based on the maximal and minimal hypothesis posts the mathematic relation among volume content of reinforcement, elastic module and wear rate. Increase in the volume fraction of reinforcement leads to improvement in the wear resistance. Unlike the Khruschov model and Zum-Gahr model, the proposed model was no longer follow linear rule. One kind of Al3Ti/Al composite with different volume content was fabricated and many wear test data were obtained to validate the correctness and universality of the model.

Similar content being viewed by others

References

San Marchi, C., Kouzeli, M., Rao, R., Lewis, J.A., Dunand, D.C.: Alumina aluminium interpenetrating phase composites with three-dimensional periodic architecture. Scr. Mater. 49, 861–866 (2003)

Hoffman, M., Skirl, S., Pompe, W.: Thermal residual strain and stresses in Al2O3/Al composites with interpenetrating networks. Acta Mater. 47, 565–577 (1999)

Eustathopoulos, N., Nicholas, M.G., Drevet, B.: Wettability at High Temperatures. Pergamon Materials Series, vol. 3. Elsevier, UK (1999)

Nayak, S.S., Murty, B.S.: Synthesis and stability of L12–A13Ti by mechanical alloying. Mater. Sci. Eng. A 367(1/2), 218–224 (2004)

Yu, H., Chen, H., Sun, L., Min, G.: Preparation of AI–Al3Ti in situ composites by direct reaction method. Rare Met. 25(1), 32–35 (2006)

Watanabe, Y., Eryu, H., Matsuura, K.: Evaluation of three-dimensional orientation of A13Ti platelet in Al-based functionally graded materials fabricated by a centrifugal casting technique. Acta Mater. 49(5), 775–783 (2001)

Zhu, X., Schoenitz, M., Dreizin, E.L.: Oxidation processes and phase changes in metastable Al–Ti mechanical alloys. Mater. Res. Soc. Symp. Proc. 800, AA3.4.1–AA3.4.6 (2005)

Wang, X., Zeng, S., Song, R., Zhang, E.: Dry sliding friction and wear behaviors of TiCp/ ZA212 composites. Trans. Nonferr. Met. Soc. China 12(3), 419–423 (2002)

Shipway, P.H., Kennedy, A.R., Wilkes, A.J.: Silding wear behaviour of aluminium-based metal matrix composites produced by a novel liquid route. Wear 216, 160–171 (1998)

Sahin, Y.: The prediction of wear resistance model for the metal matrix composites. Wear 258, 1717–1722 (2005)

Cenna, A.A., Allen, S., Page, N.W., Dastoor, P.: Modelling the three-body abrasive wear of UHMWPE particle reinforced composites. Wear 254, 581–588 (2003)

Lee, G.Y., Dharan, C.K.H., Ritchie, R.O.: A physically-based abrasive wear model for composites materials. Wear 252, 322–331 (2002)

Fu, H., Han, K., Song, J.: Wear properties of Saffil/Al, Saffil/Al2O3/Al and Saffil/SiC/Al hybrid metal matrix composites. Wear 256-4, 705–713 (2004)

Khruschov, M.M., Babichev, M.A.: Resistance to abrasive wear of structurally heterogeneous materials. Friction Wear Mach. 12, 5–24 (1958)

Zum-Gahr, K.H.: Abrasive wear of two-phase metallic materials with a coarse microstructure. In: Ludema, K.C. (ed.) International Conference on Wear of Materials, p. 793. American Society of Material Engineering, Vancouver (1985)

Axen, N., Jacobson, S.: A model for the abrasive wear resistance of multiphase materials. Wear 174, 187–199 (1994)

Yen, B.K., Dharan, C.K.H.: Amodel for the abrasive wear of fiber-reinforced polymer composites. Wear 195, 123–127 (1996)

Lee, G.Y., Dharan, C.K.H., Ritchie, R.O.: A physically-based abrasive wear model for composites materials. Wear 252, 322–331 (2002)

Queheillalt, D.T., Sypeck, D.J., Wadley, H.N.G.: Ultrasonic characterization of cellular metal structures. Mater. Sci. Eng A 323, 138–147 (2002)

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties, 2nd edn. Cambridge University Press, Cambridge (1997)

Ocelık, V., Matthews, D., De Hosson, J.Th.M.: Sliding wear resistance of metal matrix composite layers prepared by high power laser. Surf. Coat. Technol. 197, 303–315 (2005)

Acknowledgements

This work was supported by the Natural Science Foundation of Shandong Province (Y2006F03, Y2003F01) and scientific research development project of Shandong Education Office (J05B02). Part of this research was done at the Institute of Materials Science Jinan University. The authors are owing a debt of gratitude to the technical staff of institutions for their help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Wang, Y., Li, C. et al. The Dry Sliding Wear Behavior of Interpenetrating Titanium Trialuminide/Aluminium Composites. Appl Compos Mater 14, 129–144 (2007). https://doi.org/10.1007/s10443-007-9036-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-007-9036-0