Abstract

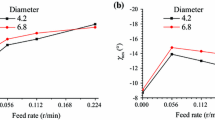

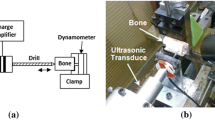

Excessive drilling forces can result in drill breakage, bone breakthrough, and thermal necrosis during bone drilling process. However, the effect of drilling process parameters, drill geometry parameters, and bone material type on drilling forces have not been fully investigated. Three designs of experiments are introduced separately to study single factor’s effect on drilling forces, identify significant geometry parameters and possible interactions for drilling forces, and formulate direct relationship between drilling forces and process parameters. The results show that thrust force and torque are increased with feed rate, drill diameter or web thickness. The effect of spindle speed, point angle, helix angle, and chisel edge angle on drilling forces is complex. The results also show that the drilling forces are affected by bone type significantly, which are highest for bovine cortical bone, and lowest for Sawbones 3401. The levels of significance of geometry parameters are identified and different for thrust force and torque, which can assist new surgical drill development. Quadratic regression equations obtained by response surface methodology can predict thrust force and torque accurately in a wide range of process parameters, which can be used to control drilling conditions for robot assisted surgeries to realize safe drilling.

Similar content being viewed by others

References

Accini, F., I. Diaz, and J. J. Gil. Using an admittance algorithm for bone drilling procedures. Computer Methods and Programs in Biomedicine 123:150 – 158, 2016.

Alam, K. Experimental and numerical analysis of conventional and ultrasonically-assisted cutting of bone. Ph.d., Loughborough University, 2009.

Alam, K., A. V. Mitrofanov, and V. V. Silberschmidt. Experimental investigations of forces and torque in conventional and ultrasonically-assisted drilling of cortical bone. Medical Engineering & Physics 33:234–239, 2011.

Alam, K., R. Muhammad, A. Shamsuzzoha, A. AlYahmadi, and N. Ahmed. Quantitative analysis of force and torque in bone drilling. The Journal of Engineering Research 14:39–48, 2017.

Allotta, B., F. Belmonte, L. Bosio, and P. Dario. Study on a mechatronic tool for drilling in the osteosynthesis of long bones: Tool/bone interaction, modeling and experiments. Mechatronics 6:447 – 459, 1996.

Augustin, G., T. Zigman, S. Davila, T. Udilljak, T. Staroveski, D. Brezak, and S. Babic. Cortical bone drilling and thermal osteonecrosis. Clinical Biomechanics 27:313–325, 2012.

Aziz, M. H., M. A. Ayub, and R. Jaafar. Force control algorithm for detection of break-through bone drilling. Journal of Mechanical Engineering 9:1–4, 2012.

Aziz, M. H., M. A. Ayub, and R. Jaafar. Real-time algorithm for detection of breakthrough bone drilling. Procedia Engineering 41:352–359, 2012.

Basiaga, M., Z. Paszenda, J. Szewczenko, and M. Kaczmarek. Numerical and experimental analyses of drills used in osteosynthesis. Acta Bioeng Biomech 13:29–36, 2011.

Boiadjiev, T., G. Boiadjiev, K. Delchev, K. Zagurski, and R. Kastelov. Far cortex automatic detection aimed for partial or full bone drilling by a robot system in orthopaedic surgery. Biotechnology & Biotechnological Equipment 31:200–205, 2017.

Cook, N. H. Manufacturing Analysis, Reading, Mass. Addison-Wesley, Boston, 1966.

Cseke, A. and R. Heinemann. The effects of cutting parameters on cutting forces and heat generation when drilling animal bone and biomechanical test materials. Medical Engineering & Physics 51:24 – 30, 2018.

Currey, J. D. The Mechanical Adaptations of Bones, Princeton University Press,NY 1984.

Daz, I., J. J. Gil, and M. Louredo. Bone drilling methodology and tool based on position measurements. Computer Methods and Programs in Biomedicine 112:284–292, 2013.

Eriksson, A. R. and T. Albrektsson. Temperature threshold levels for heat-induced bone tissue injury: A vital-microscopic study in the rabbit. The Journal of Prosthetic Dentistry 50:101–107, 1983.

Karalis, T. and P. Galanos. Research on the mechanical impedance of human bone by a drilling test. Journal of Biomechanics 15:561–581, 1982.

Karmani, S. The thermal properties of bone and the effects of surgical intervention. Current Orthopaedics 20:52 – 58, 2006.

Langella, A., L. Nele, and A. Maio. A torque and thrust prediction model for drilling of composite materials. Composites Part A: Applied Science and Manufacturing 36:83–93, 2005.

Lee, J., C. L. Chavez, and J. Park. Parameters affecting mechanical and thermal responses in bone drilling: a review. J. Biomech., 2018.

Lee, J., B. A. Gozen, and O. B. Ozdoganlar. Modeling and experimentation of bone drilling forces. Journal of Biomechanics 45:1076–1083, 2012.

Lee, W.-Y. and C.-L. Shih. Control and breakthrough detection of a three-axis robotic bone drilling system. Mechatronics 16:73–84, 2006.

Louredo, M., I. Daz, and J. J. Gil. Dribon: A mechatronic bone drilling tool. Mechatronics 22:1060–1066, 2012.

Lughmani, W. A., K. Bouazza-Marouf, and I. Ashcroft. Finite element modeling and experimentation of bone drilling forces. Journal of Physics: Conference Series 451:012034, 2013.

Lughmani, W. A., K. Bouazza-Marouf, and I. Ashcroft. Drilling in cortical bone: a finite element model and experimental investigations. Journal of the Mechanical Behavior of Biomedical Materials 42:32 – 42, 2015.

Lundskog, J. Heat and bone tissue: an experimental investigation of the thermal properties of bone and threshold levels for thermal injury. Scandinavian journal of plastic and reconstructive surgery 9:1–80, 1972.

Macavelia, T., M. Salahi, M. Olsen, M. Crookshank, E. H. Schemitsch, A. Ghasempoor, F. Janabi-Sharifi, and R. Zdero. Biomechanical measurements of surgical drilling force and torque in human versus artificial femurs. Journal of Biomechanical Engineering 134:124503, 2012.

Ong, F. and K. Bouazza-Marouf. The detection of drill bit break-through for the enhancement of safety in mechatronic assisted orthopaedic drilling. Mechatronics 9:565 – 588, 1999.

Ong, F. R. and K. Bouazza-Marouf. Drilling of bone: A robust automatic method for the detection of drill bit break-through. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine 212:209–221, 1998.

Pichler, W., P. Mazzurana, H. Clement, S. Grechenig, R. Mauschitz, and W. Grechenig. Frequency of instrument breakage during orthopaedic procedures and its effects on patients. The Journal of Bone & Joint Surgery 90:2652–2654, 2008.

Powers, M. J. The mechanics of bone drilling: Experiment and finite element predictions. Ph.d., University of Calgary, 2006.

Price, M., S. Molloy, M. Solan, A. Sutton, and D. Ricketts. The rate of instrument breakage during orthopaedic procedures. International Orthopaedics 26:185–187, 2002.

Reilly, D. T. and A. H. Burstein. The mechanical properties of cortical bone. JBJS 56:1001–1022, 1974.

Reilly, D. T. and A. H. Burstein. The elastic and ultimate properties of compact bone tissue. Journal of Biomechanics 8:393 – 405, 1975.

Sang, H., R. Monfaredi, E. Wilson, H. Fooladi, D. Preciado, and K. Cleary. A new surgical drill instrument with force sensing and force feedback for robotically assisted otologic surgery. Journal of Medical Devices 11:031009; 2017.

Singh, G., V. Jain, and D. Gupta. Comparative study for surface topography of bone drilling using conventional drilling and loose abrasive machining. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine 229:225–231, 2015. PMID: 25833998.

Soriano, J., A. Garay, P. Aristimuño, and P. J. Arrazola. Study and improvement of surgical drill bit geometry for implant site preparation. The International Journal of Advanced Manufacturing Technology 74:615–627, 2014.

Sui, J. and N. Sugita. Optimization of drill bits for bone drilling procedure. In: 13th International Manufacturing Science and Engineering Conference, p. V001T05A001, 2018.

Sui, J., N. Sugita, K. Ishii, K. Harada, and M. Mitsuishi. Mechanistic modeling of bone-drilling process with experimental validation. Journal of Materials Processing Technology 214:1018–1026, 2014.

Sui, J., N. Sugita, and M. Mitsuishi. Thermal modeling of temperature rise for bone drilling with experimental validation. Journal of Manufacturing Science and Engineering 137:061008, 2015.

Tuijthof, G. J. M., C. Fruhwirt, and C. Kment. Influence of tool geometry on drilling performance of cortical and trabecular bone. Medical Engineering & Physics 35:1165–1172, 2013.

Udiljak, T., D. Ciglar, and S. Skoric. Investigation into bone drilling and thermal bone necrosis. Advances in Production Engineering& Management 2:103–12, 2007.

Wang, Y., M. Cao, Y. Zhao, G. Zhou, W. Liu, and D. Li. Experimental investigations on microcracks in vibrational and conventional drilling of cortical bone. Journal of Nanomaterials 2013:5, 2013.

Acknowledgments

This research work was sponsored by the Japan Ministry of Internal Affairs and Communications, Strategic Information and Communication R&D Promotion Programme [Grant No. 121803005], start-up funding of the 100 Young Talents Programme of Guangdong University of Technology [Grant No. 220413188], National Natural Science Foundation of China [Grant No. 51805091], and Natural Science Foundation of Guangdong Province [Grant No. 2018A030313713].

Conflict of interest

The authors declare that there is no conflict of interest associated with the presented work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editor Sean S. Kohles oversaw the review of this article.

Rights and permissions

About this article

Cite this article

Sui, J., Sugita, N. Experimental Study of Thrust Force and Torque for Drilling Cortical Bone. Ann Biomed Eng 47, 802–812 (2019). https://doi.org/10.1007/s10439-018-02196-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10439-018-02196-8