Abstract

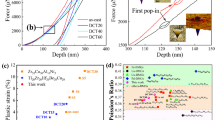

The origin of cavitation in brittle metallic glasses (MGs) is traced to the high degree of atomic density fluctuations. Purposely tuning the inherent structure to suppress cavitation has been a longstanding concern. Here we investigate the effect of high pressure heat treatment (HPHT) on the cavitation performance of a brittle Fe80P20 MG through molecular dynamics (MD) simulations. We found that HPHT can induce rejuvenation and effectively suppress cavitation. The spatial heterogeneity reduces with the applied pressure and temperature, resulting in a relatively uniform distribution of P atoms. Our analysis demonstrates that the local atomic structure can be excited from a “liquid-like” state to a “solid-like” one by HPHT, where larger stress is required to initiate cavitation. This work provides new insight into the understanding of the relationship between spatial heterogeneity and cavitation behavior of MGs.

摘要

脆性金属玻璃的空化现象可追溯其本征的高原子密度涨落. 有目的地调节金属玻璃内部结构以抑制其空化行为一直是被关注的问题. 本文通过分子动力学模拟研究了高压热处理对脆性Fe80P20金属玻璃空化行为的影响. 高压热处理可诱导Fe80P20金属玻璃发生年轻化, 有效抑制空化的发生. 伴随压力和温度的增加, Fe80P20金属玻璃的空间异质性逐渐减小, 同时磷原子的分布变得相对均匀. 分析表明, 高压热处理可诱导Fe80P20金属玻璃局部原子结构从“类液态”转变为“类固态”, 致使空化需要更大的外加应力诱发. 上述结果为理解金属玻璃的空间异质性和空化行为之间的关联规律提供了新的思路.

Similar content being viewed by others

References

M. Ashby, and A. Greer, Metallic glasses as structural materials, Scr. Mater. 54, 321 (2006).

C. A. Schuh, T. C. Hufnagel, and U. Ramamurty, Mechanical behavior of amorphous alloys, Acta Mater. 55, 4067 (2007).

Q. Li, S. S. Liu, X. H. Wang, T. Yang, C. Dong, J. T. Hu, and Y. Q. Jiang, Mechanical and corrosion properties of Ti-Ni-Cu-Zr metallic glass matrix composites, J. Alloys Compd. 727, 1344 (2017).

W. H. Wang, C. Dong, and C. H. Shek, Bulk metallic glasses, Mater. Sci. Eng.-R-Rep. 44, 45 (2004).

A. Inoue, and A. Takeuchi, Recent development and application products of bulk glassy alloys, Acta Mater. 59, 2243 (2011).

X. Song, X. Wu, L. Dai, and M. Jiang, Comparative study of amorphous and crystalline Zr-based alloys in response to nanosecond pulse laser ablation, Acta Mech. Sin. 38, 221480 (2022).

A. L. Greer, Metallic glasses, Science 267, 1947 (1995).

M. Chen, A. Inoue, W. Zhang, and T. Sakurai, Extraordinary plasticity of ductile bulk metallic glasses, Phys. Rev. Lett. 96, 245502 (2006).

H. F. Li, and Y. F. Zheng, Recent advances in bulk metallic glasses for biomedical applications, Acta Biomater. 36, 1 (2016).

P. Du, T. Xiang, Z. Cai, and G. Xie, The influence of porous structure on the corrosion behavior and biocompatibility of bulk Ti-based metallic glass, J. Alloys Compd. 906, 164326 (2022).

J. Qiang, and K. Tsuchiya, Concurrent solid-state amorphization and structural rejuvenation in Zr-Cu-Al alloy by high-pressure torsion, Mater. Lett. 204, 138 (2017).

A. Concustell, F. O. Mear, S. Surinach, M. D. Baro, and A. L. Greer, Structural relaxation and rejuvenation in a metallic glass induced by shot-peening, Philos. Mag. Lett. 89, 831 (2009).

Y. Tong, T. Iwashita, W. Dmowski, H. Bei, Y. Yokoyama, and T. Egami, Structural rejuvenation in bulk metallic glasses, Acta Mater. 86, 240 (2015).

O. Haruyama, K. Kisara, A. Yamashita, K. Kogure, Y. Yokoyama, and K. Sugiyama, Characterization of free volume in cold-rolled Zr55 Cu30Ni5Al10 bulk metallic glasses, Acta Mater. 61, 3224 (2013).

B. Sarac, F. Spieckermann, A. Rezvan, C. Gammer, L. Krämer, J. T. Kim, J. Keckes, R. Pippan, and J. Eckert, Annealing-assisted high-pressure torsion in Zr55Cu30Al10Ni5 metallic glass, J. Alloys Compd. 784, 1323 (2019).

Y. Tang, H. Zhou, H. Lu, X. Wang, Q. Cao, D. Zhang, W. Yang, and J. Z. Jiang, Extra plasticity governed by shear band deflection in gradient metallic glasses, Nat. Commun. 13, 2120 (2022).

A. Das, E. M. Dufresne, and R. Maaß, Structural dynamics and rejuvenation during cryogenic cycling in a Zr-based metallic glass, Acta Mater. 196, 723 (2020).

J. Saida, R. Yamada, and M. Wakeda, Recovery of less relaxed state in Zr-Al-Ni-Cu bulk metallic glass annealed above glass transition temperature, Appl. Phys. Lett. 103, 221910 (2013).

X. Wang, Y. Shao, P. Gong, and K. F. Yao, The effect of simulated thermal cycling on thermal and mechanical stability of a Ti-based bulk metallic glass, J. Alloys Compd. 575, 449 (2013).

H. F. Zhou, C. Zhong, Q. P. Cao, S. X. Qu, X. D. Wang, W. Yang, and J. Z. Jiang, Non-localized deformation in metallic alloys with amorphous structure, Acta Mater. 68, 32 (2007).

Y. Chen, and L. Dai, Failure behavior and criteria of metallic glasses, Acta Mech. Sin. 38, 121449 (2022).

I. Singh, T. F. Guo, P. Murali, R. Narasimhan, Y. W. Zhang, and H. J. Gao, Cavitation in materials with distributed weak zones: Implications on the origin of brittle fracture in metallic glasses, J. Mech. Phys. Solids 61, 1047 (2013).

X. Lu, Y. Hou, Y. Tie, C. Li, and C. Zhang, Crack nucleation and propagation simulation in brittle two-phase perforated/particulate composites by a phase field model, Acta Mech. Sin. 36, 493 (2020).

P. Murali, T. F. Guo, Y. W. Zhang, R. Narasimhan, Y. Li, and H. J. Gao, Atomic scale fluctuations govern brittle fracture and cavitation behavior in metallic glasses, Phys. Rev. Lett. 107, 215501 (2011).

R. Casalini, and C. M. Roland, Scaling of the supercooled dynamics and its relation to the pressure dependences of the dynamic crossover and the fragility of glass formers, Phys. Rev. B 71, 014210 (2005).

C. M. Roland, S. Hensel-Bielowka, M. Paluch, and R. Casalini, Supercooled dynamics of glass-forming liquids and polymers under hydrostatic pressure, Rep. Prog. Phys. 68, 1405 (2005).

S. Li, J. C. Zhang, and Z. D. Sha, Mechanical behavior of metallic glasses with pressure-promoted thermal rejuvenation, J. Alloys Compd. 848, 156597 (2020).

Y. Tang, Q. K. Zhao, H. F. Zhou, W. Hu, T. D. Xu, L. Zheng, R. K. Nutor, X. D. Wang, Q. P. Cao, D. X. Zhang, G. Sha, H. K. Wang, and J. Z. Jiang, Tailoring microstructure of metallic glass for delocalized plasticity by pressure annealing: Forward and inverse studies, Acta Mater. 220, 117282 (2021).

M. I. Mendelev, D. J. Sordelet, and M. J. Kramer, Using atomistic computer simulations to analyze x-ray diffraction data from metallic glasses, J. Appl. Phys. 102, 043501 (2007).

G. J. Ackland, M. I. Mendelev, D. J. Srolovitz, S. Han, and A. V. Barashev, Development of an interatomic potential for phosphorus impurities in-iron, J. Phys.-Condens. Matter 16, S2629 (2004).

J. L. Finney, Random packings and the structure of simple liquids. I. The geometry of random close packing, Proc. R. Soc. Lond. A 319, 479 (1970).

M. Li, C. Z. Wang, S. G. Hao, M. J. Kramer, and K. M. Ho, Structural heterogeneity and medium-range order in ZrxCu100−x metallic glasses, Phys. Rev. B 80, 184201 (2009).

Q. Yu, X. D. Wang, H. B. Lou, Q. P. Cao, and J. Z. Jiang, Atomic packing in Fe-based metallic glasses, Acta Mater. 102, 116 (2016).

P. J. Steinhardt, D. R. Nelson, and M. Ronchetti, Bond-orientational order in liquids and glasses, Phys. Rev. B 28, 784 (1983).

Y. Tang, H. F. Zhou, X. D. Wang, Q. P. Cao, D. X. Zhang, and J. Z. Jiang, Origin of different thermal cycling effects in Fe80P20 and Ni60 Nb40 metallic glasses, Mater. Today Phys. 17, 100349 (2021).

Q. P. Cao, J. W. Liu, K. J. Yang, F. Xu, Z. Q. Yao, A. Minkow, H. J. Fecht, J. Ivanisenko, L. Y. Chen, X. D. Wang, S. X. Qu, and J. Z. Jiang, Effect of pre-existing shear bands on the tensile mechanical properties of a bulk metallic glass, Acta Mater. 58, 1276 (2010).

S. Scudino, B. Jerliu, K. B. Surreddi, U. Kühn, and J. Eckert, Effect of cold rolling on compressive and tensile mechanical properties of Zr52.5Ti5Cu18Ni14.5Al10 bulk metallic glass, J. Alloys Compd. 509, S128 (2011).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11902289, 12172324, 12222210, and 12202381), Zhejiang University K. P. Chao’s High Technology Development Foundation, and China Postdoctoral Science Foundation (Grant No. 2022M712758).

Author information

Authors and Affiliations

Corresponding author

Additional information

Author contributions

Haofei Zhou designed the research. Yao Tang and Haofei Zhou wrote the first draft of the manuscript. Yao Tang processed the simulation data. Yao Tang and Haofei Zhou organized the manuscript. Yao Tang and Haofei Zhou revised and edited the final version.

Rights and permissions

About this article

Cite this article

Tang, Y., Zhou, H. High pressure heat treatment tuning cavitation behavior in FeP metallic glass. Acta Mech. Sin. 39, 122413 (2023). https://doi.org/10.1007/s10409-022-22413-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-022-22413-x