Abstract

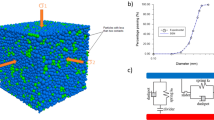

The indentation test is a localized testing technique; therefore, the role of the material size-effect and local non-uniformity is of much importance. The influence of the heterogeneity in size-independent materials has been studied previously. The present work detailedly investigated the influence of the material size-effect and heterogeneity (inclusions near the indenter tip) on the indentation hardness using a size-dependent strain gradient plastic theory. And it was found that when considering the material size-effect, shallow hard inclusions in the heterogeneous materials more significantly enhance the material indentation hardness compared with the size-independent materials which are based on the conventional plastic theory. This hardening effect is believed to be related to the elevation of the load and local constraints of large deformation. The effect of material inhomogeneity mainly comes from the non-uniformity of the structure rather than the inclusion modulus itself especially when the size-effect is involved, and the transition range of the inclusion modulus’ influence is pretty narrow. The effect of non-uniformity becomes negligible after the initial inclusion depth is larger than its diameter. The horizontal offset of the indenter from the inclusion is also of much sensitivity to the influence of the heterogeneous indentation. This paper focuses on the scaling relationships in micro- and nanoindentation, the influence of non-uniformity in microscopic materials is studied and supplemented as well.

摘要

压痕实验是一种材料局部力学性能的测试方法. 因此, 材料的尺度效应以及局部非均匀性在其中显得尤为重要. 分别考虑局部非均匀性或尺度效应的情况已经得到了研究, 而本文将使用应变梯度塑性理论进一步研究跨尺度的局部异构(压头尖端附近的颗粒夹杂)对压痕响应的影响. 研究发现, 相较于基于传统塑性理论的尺度无关结果, 考虑尺度效应时压头尖端附近的硬质夹杂能更加显著地提高压痕硬度, 而这一硬化效应主要是应变梯度塑性材料的压痕载荷的升高和压头下方局部大变形受尺度效应约束所导致的. 这种夹杂所致的硬度提升是其结构的非均匀性而非夹杂自身的性质所主导的, 夹杂自身性质变化对压痕响应影响明显的区间相对较窄. 当夹杂深度大于其自身直径时, 其对整体的压痕响应的影响逐渐变得可以忽略, 此外, 压头与夹杂水平位置偏移的影响也在本文中得到了讨论. 本文主要研究了微纳米尺度下颗粒异构夹杂对压痕响应的影响, 从而进一步加深了对跨尺度压痕标度律的认识.

Similar content being viewed by others

References

A. K. Bhattacharya, and W. D. Nix, Finite element simulation of indentation experiments. Int. J. Solids Struct. 24, 881 (1988).

W. C. Oliver, and G. M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

S. N. Magonov, V. Elings, and M. H. Whangbo, Phase imaging and stiffness in tapping-mode atomic force microscopy. Surf. Sci. 375, L385 (1997).

A. Fischer-Cripps, and D. Nicholson, Nanoindentation. Mechanical engineering series. Appl. Mech. Rev. 57, B12 (2004).

B. Bhushan, and X. Li, Nanomechanical characterisation of solid surfaces and thin films. Int. Mater. Rev. 48, 125 (2003).

S. Jiapeng, L. Cheng, J. Han, A. Ma, and L. Fang, Nanoindentation induced deformation and pop-in events in a silicon crystal: Molecular dynamics simulation and experiment. Sci. Rep. 7, 10282 (2017).

M. Liu, C. Lu, K. A. Tieu, C. T. Peng, and C. Kong, A combined experimental-numerical approach for determining mechanical properties of aluminum subjects to nanoindentation. Sci. Rep. 5, 15072 (2015).

S. Varughese, M. S. R. N. Kiran, U. Ramamurty, and G. R. Desiraju, Nanoindentation in crystal engineering: quantifying mechanical properties of molecular crystals. Angew. Chem. Int. Ed. 52, 2701 (2013).

J. B. Vella, I. S. Adhihetty, K. Junker, and A. A. Volinsky, Mechanical properties and fracture toughness of organo-silicate glass (OSG) low-k dielectric thin films for microelectronic applications. Int. J. Fract. 119/120, 487 (2003).

M. Li, H. X. Zhang, Z. L. Zhao, and X. Q. Feng, Surface effects on cylindrical indentation of a soft layer on a rigid substrate. Acta Mech. Sin. 36, 422 (2020).

Y. T. Cheng, and C. M. Cheng, Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 73, 614 (1998).

Y. T. Cheng, and C. M. Cheng, Scaling approach to conical indentation in elastic-plastic solids with work hardening. J. Appl. Phys. 84, 1284 (1998).

Y. T. Cheng, Z. Li, and C. M. Cheng, Scaling relationships for indentation measurements. Philos. Mag. A 82, 1821 (2002).

Y. T. Cheng, and C. M. Cheng, Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng.-R-Rep. 44, 91 (2004).

F. Pöhl, Determination of unique plastic properties from sharp indentation. Int. J. Solids Struct. 171, 174 (2019).

E. Bazzaz, A. Darvizeh, M. Alitavoli, and M. Y. Tooski, Implementation of the new minimum resultant error approach to extract elastic-plastic properties of titanium nitride thin film by nanoindentation, finite element analysis, and modified dimensional analysis. Proc. Instit. Mech. Eng. Part C-J. Mech. Eng. Sci. 234, 3280 (2020).

L. Lu, M. Dao, P. Kumar, U. Ramamurty, G. E. Karniadakis, and S. Suresh, Extraction of mechanical properties of materials through deep learning from instrumented indentation. Proc. Natl. Acad. Sci. USA 117, 7052 (2020).

H. Lee, W. Y. Huen, V. Vimonsatit, and P. Mendis, An investigation of nanomechanical properties of materials using nanoindentation and artificial neural network. Sci. Rep. 9, 13189 (2019).

M. Dao, N. Chollacoop, K. J. Van Vliet, T. A. Venkatesh, and S. Suresh, Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

N. Chollacoop, M. Dao, and S. Suresh, Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 (2003).

M. Zhao, N. Ogasawara, N. Chiba, and X. Chen, A new approach to measure the elastic-plastic properties of bulk materials using spherical indentation. Acta Mater. 54, 23 (2006).

X. Chen, N. Ogasawara, M. Zhao, and N. Chiba, On the uniqueness of measuring elastoplastic properties from indentation: The indistinguishable mystical materials. J. Mech. Phys. Solids 55, 1618 (2007).

M. Q. Le, Material characterization by dual sharp indenters. Int. J. Solids Struct. 46, 2988 (2009).

Z. Yu, Z. Lin, and Y. Wei, Closed-form functions of cross-scale indentation scaling relationships based on a strain gradient plasticity theory. Philos. Mag. 101, 1305 (2021).

H. Ma, Y. Wei, J. Song, and L. Liang, Mechanical behavior and size effect of the staggered bio-structure materials. Mech. Mater. 126, 47 (2018).

R. Zhang, T. Wang, and R. Guo, Modeling of interphases in multiple heterogeneities reinforced composites using Voronoi cell finite elements. Acta Mech. Sin. 36, 887 (2020).

Z. Wang, X. Zhong, L. Jiang, F. Qi, X. Ouyang, J. Wang, B. Liao, and J. Luo, Effect of interfacial delamination on coating crack in thick diamond-like carbon coatings under indentation. Acta Mech. Sin. 36, 524 (2020).

Z. J. Yu, and Y. G. Wei, A study of indentation scaling relationships of elastic-perfectly plastic solids with an inclusion near the conical indenter tip. Sci. China Technol. Sci. 62, 721 (2019).

Z. Yu, Z. Lin, and Y. Wei, Investigation on cross-scale indentation scaling relationships of elastic — plastic solids. Acta Mech. 232, 1479 (2021).

J. L. Bucaille, S. Stauss, E. Felder, and J. Michler, Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663 (2003).

H. Zhang, Y. Xu, Y. Gan, Z. Chang, E. Schlangen, and B. Šavija, Microstructure informed micromechanical modelling of hydrated cement paste: Techniques and challenges. Construct. Building Mater. 251, 118983 (2020).

Y. Gaillard, and F. Amiot, Grid nano-indentation as full-field measurements. Compos. Part A-Appl. Sci. Manuf. 132, 105807 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11890681, 12032001, and 11521202).

Rights and permissions

About this article

Cite this article

Yu, Z., Wei, Y. Cross-scale indentation scaling relationships of strain gradient plastic solids: Influence of inclusions near the indenter tip. Acta Mech. Sin. 38, 221257 (2022). https://doi.org/10.1007/s10409-021-09016-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-021-09016-0