Abstract

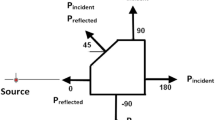

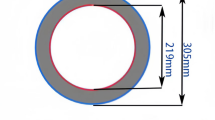

The application of hard/soft composite structure in personnel armor for blast mitigation is relatively practical and effective in realistic protection engineering, such as the shell/liner system of the helmet. However, there is still lacking a reliable experimental methodology to effectively evaluate the blast mitigation performance when the structure directly contacts the protected target, which limits the development of protection structures. In this paper, we proposed a new method to evaluate experimentally and numerically the blast mitigation performance of hard/soft composite structures. The blast mitigation mechanism is analyzed. The hard/soft structures were composed of ultra-high molecular weight polyethylene (UHMWPE) composite and expanded polyethylene (EPE) foam. In field explosion experiment, a 7.0 kg trinitrotoluene (TNT) spherical charge is used to generate blast waves at a 3.8 m stand-off distance. A pressure test device is designed to support the tested structure and measure the transmitted blast pressure pulses after passing through the structure. Experimental results indicate that the hard/soft structures can mitigate the blast pressure pulse into the triangular pressure pulse, through making the pulse profile flatter, reducing the pressure amplitude, and delaying the pulse arrival time. Specifically, the combination of 7 mm UHMWPE composite and 20 mm EPE foam can reduce the blast pressure amplitude by 40%. Correspondingly, the finite element simulation is also carried out to understand the blast mitigation mechanism. The numerical results indicate that the regulation for blast pressure pulses mainly complete at the hard/soft interface, which is attributed to the reflection of pressure waves at the interface and the deformation of the soft layer compressed by the hard layer possessing kinetic energy. Furthermore, based on these analyses, the corresponding theoretical model is proposed, and it can well explain the experimental and numerical results. This study is meaningful for evaluating and designing high-performance blast mitigation structures.

摘要

现实防护工程中, 硬/软复合结构在人员装甲(如头盔的外壳/衬里系统)中的应用可以有效减轻爆炸伤害. 由于缺乏有效可靠的实验方法评估防护结构的防爆性能, 直接接触型防护结构的发展受到限制. 本文针对硬/软复合材料结构的防爆性能测试提出一种新的实验及数值评估方法, 并对其防爆机理进行了分析. 受测的硬/软结构由超高分子量聚乙烯(UHMWPE)复合材料和膨胀聚乙烯(EPE)泡沫组成. 现场爆炸试验通过7.0 kg TNT球形炸药在3.8 m处产生的爆炸波来完成. 设计了一种压力测试装置用于支撑被测结构并测量穿透防护结构的爆炸压力脉冲. 实验结果表明, 通过使脉冲波形更平坦、减小压力幅度和延迟脉冲到达时间, 硬/软结构可以将爆炸压力脉冲减弱为三角形压力脉冲. 7 mm UHMWPE复合材料和20 mm EPE泡沫的组合防护结构可将爆炸压力振幅降低40%. 通过有限元模拟分析爆炸缓解机制. 数值结果表明, 爆炸压力脉冲的衰减主要发生在硬/软界面上, 通过界面反射压力波和软材料层变形吸收动能来完成. 在此基础上提出的理论模型可以很好地解释实验和数值结果, 对评价和设计高性能的防爆结构具有重要意义.

Similar content being viewed by others

References

W. E. Baker, Explosions in Air (The University of Texas Press, Austin, 1973).

N. M. Elsayed, Toxicology of blast overpressure, Toxicology 121, 1 (1997).

W. Peng, Z. Zhang, G. Gogos, and G. Gazonas, Fluid structure interactions for blast wave mitigation, J. Appl. Mech. 78, 031016 (2011).

J. M. Wightman, and S. L. Gladish, Explosions and blast injuries, Ann. Emergency Med. 37, 664 (2001).

K. H. Taber, D. L. Warden, and R. A. Hurley, Blast-related traumatic brain injury: what is known? JNP 18, 141 (2006).

J. Boutillier, C. Deck, P. Magnan, P. Naz, and R. Willinger, A critical literature review on primary blast thorax injury and their outcomes, J. Trauma Acute Care Surg. 81, 371 (2016).

J. H. Stuhmiller, Biological response to blast overpressure: a summary of modeling, Toxicology 121, 91 (1997).

M. Grujicic, W. C. Bell, B. Pandurangan, and T. He, Blast-wave impact-mitigation capability of polyurea when used as helmet suspension-pad material, Mater. Des. 31, 4050 (2010).

W. C. Moss, M. J. King, and E. G. Blackman, Skull flexure from blast waves: a mechanism for brain injury with implications for helmet design, Phys. Rev. Lett. 103, 108702 (2009).

T. Rahimzadeh, E. M. Arruda, and M. D. Thouless, Design of armor for protection against blast and impact, J. Mech. Phys. Solids 85, 98 (2015).

W. He, M. Han, S. Wang, P. Goudeau, E. Le Bourhis, and P. O. Renault, Elastic property determination of nanostructured W/Cu multilayer films on a flexible substrate, Acta Mech. Sin. 35, 1210 (2019).

Q. Q. Li, Z. C. He, E. Li, P. Liu, X. Y. Lin, and Y. Wu, Design of resonant structures in resin matrix to mitigate the blast wave with a very wide frequency range, Smart Mater. Struct. 29, 045042 (2020).

J. Cheng, Z. L. Liu, C. C. Luo, T. Li, Z. J. Li, Y. Kang, and Z. Zhuang, Revealing the high-frequency attenuation mechanism of polyureamatrix composites, Acta Mech. Sin. 36, 130 (2020).

E. Courtney, A. Courtney, and M. Courtney, Shock tube design for high intensity blast waves for laboratory testing of armor and combat materiel, Defence Tech. 10, 245 (2014).

Z. Li, Z. Du, X. You, Z. Liu, J. Cheng, C. Luo, D. Chu, S. Ning, Y. Kang, C. Yang, and Z. Zhuang, Numerical study on dynamic mechanism of brain volume and shear deformation under blast loading, Acta Mech. Sin. 35, 1104 (2019).

K. Ackland, C. Anderson, and T. D. Ngo, Deformation of polyureacoated steel plates under localised blast loading, Int. J. Impact Eng. 51, 13 (2013).

Y. L. Young, Z. Liu, and W. Xie, Fluid-structure and shock-bubble interaction effects during underwater explosions near composite structures, J. Appl. Mech. 76, 051303 (2009).

M. Gerdooei, M. J. Rezaei, and H. Ghaforian Nosrati, Improving the performance of a multi-layer armored system subjected to shock loading of an underwater explosion, Mech. Adv. Mater. Struct., 1 (2020).

S. A. Tekalur, A. Shukla, and K. Shivakumar, Blast resistance of polyurea based layered composite materials, Composite Struct. 84, 271 (2008).

H. Arora, P. A. Hooper, and J. P. Dear, Dynamic response of full-scale sandwich composite structures subject to air-blast loading, Compos. Part A-Appl. Sci. Manufact. 42, 1651 (2011).

G. Wei, Y. Jin, and L. Wu, Geometric and material nonlinearities of sandwich beams under static loads, Acta Mech. Sin. 36, 97 (2020).

E. Wang, N. Gardner, and A. Shukla, The blast resistance of sandwich composites with stepwise graded cores, Int. J. Solids Struct. 46, 3492 (2009).

L. Zhang, R. Hebert, J. T. Wright, A. Shukla, and J. H. Kim, Dynamic response of corrugated sandwich steel plates with graded cores, Int. J. Impact Eng. 65, 185 (2014).

N. Gardner, E. Wang, and A. Shukla, Performance of functionally graded sandwich composite beams under shock wave loading, Composite Struct. 94, 1755 (2012).

B. J. Ramirez, and V. Gupta, Evaluation of novel temperature-stable viscoelastic polyurea foams as helmet liner materials, Mater. Des. 137, 298 (2018).

L. J. Gibson, and M. F. Ashby, Cellular Solids: Structure and Properties (Cambridge University Press, Cambridge, 1999).

A. F. Fedotov, Model of homogenisation for analysing the effect of micrometre pore sizes on the elastic moduli of porous materials, Acta Mech. Sin. 35, 1060 (2019).

S. Wang, Z. Zheng, Y. Ding, C. Zhu, and J. Yu, Dynamic crushing of cellular materials: A particle velocity-based analytical method and its application, Acta Mech. Sin. 35, 839 (2019).

M. Aleyaasin, J. J. Harrigan, and S. R. Reid, Air-blast response of cellular material with a face plate: An analytical-numerical approach, Int. J. Mech. Sci. 91, 64 (2015).

A. Leonard, and C. Daraio, Stress wave anisotropy in centered square highly nonlinear granular systems, Phys. Rev. Lett. 108, 214301 (2012).

H. Bornstein, S. Di Placido, S. Ryan, A. C. Orifici, and A. P. Mouritz, Effect of standoff on near-field blast mitigation provided by water-filled containers, J. Appl. Mech. 86, 071003 (2019).

H. N. G. Wadley, K. P. Dharmasena, M. Y. He, R. M. McMeeking, A. G. Evans, T. Bui-Thanh, and R. Radovitzky, An active concept for limiting injuries caused by air blasts, Int. J. Impact Eng. 37, 317 (2010).

J. Li, T. Ma, C. Huang, X. Huang, Y. Kang, Z. Long, and M. Liu, Protective mechanism of helmet under far-field shock wave, Int. J. Impact Eng. 143, 103617 (2020).

R. G. Barsoum, Elastomeric Polymers With High Rate Sensitivity: Applications in Blast, Shockwave, and Penetration Mechanics (William Andrew, 2015).

J. Boutillier, S. De Mezzo, and C. Deck, In: Shock-wave interaction with reduced-scale simplified torso surrogates: Proceedings of the IRCOBI Conference (2016).

F. J. Mostert, I. M. Snyman, and M. Olivier, An experimental technique to characterize the dynamic response of materials, or material combinations, to explosive blast, J. Appl. Mech. 78, 051008 (2011).

M. F. Sonnenschein, E. Nicoli, L. Ma, and B. L. Wendt, Impact mitigation in layered polymeric structures, Polymer 131, 25 (2017).

H. van der Werff, and U. Heisserer, High-performance ballistic fibers: Ultra-high molecular weight polyethylene (UHMWPE). In: Advanced Fibrous Composite Materials For Ballistic Protection (Woodhead Publishing, 2016). pp. 71–107.

T. Lässig, L. Nguyen, M. May, W. Riedel, U. Heisserer, H. van der Werff, and S. Hiermaier, A non-linear orthotropic hydrocode model for ultra-high molecular weight polyethylene in impact simulations, Int. J. Impact Eng. 75, 110 (2015).

S. Abe, and M. Yamaguchi, Study on the foaming of crosslinked polyethylene, J. Appl. Polym. Sci. 79, 2146 (2001).

J. Henrych, and R. Major, The Dynamics of Explosion and Its Use (Elsevier, Amsterdam, 1979).

ABAQUS version 6.14-1, User Documentation, Dassault Systems (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Science Challenge Project (Grant No. TZ2018002), the National Natural Science Foundation of China (Grant Nos. 11972205 and 11722218), the National Key Research Development Program of China (Grant No. 2017YFB0702003), and Opening Project of Applied Mechanics and Structure Safety Key Laboratory of Sichuan Province.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Yang, F., Li, Z., Zhuang, Z. et al. Evaluating the blast mitigation performance of hard/soft composite structures through field explosion experiment and numerical analysis. Acta Mech. Sin. 38, 121238 (2022). https://doi.org/10.1007/s10409-021-09001-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-021-09001-x