Abstract

Droplet-based microfluidics offers unique advantages to create platforms that fabricate functionalized particles with increased accessibility, robustness, and simplicity. Herein we present a three-phase microfluidic device that can control the flow pattern to directly generate either core–shell or hole–shell microparticles. The major benefits of this device are the ease of controlling the morphology of the compound droplets by the flow rates and thus the microstructure of the synthesized microparticles. The transition between flow patterns enables the generation of either core–shell particles or Janus particles in a single device. We further show the versatility of the proposed device in fabrication of functionalized particles: the hole size of the hole–shell microparticle can be fine-tuned while its outer diameter is kept constant, and by adding Fe3O4 nanoparticles into the photocurable phase, the obtained magnetoresponsive microparticle can move rotationally or translationally under an external magnetic field. We anticipate that the present method could facilitate the fabrication of the functional microparticles for diverse applications.

Graphic abstract

Similar content being viewed by others

References

Han, S.W., Choi, S.E., Chang, D.H., et al.: Colloidal pixel-based micropatterning using uniform Janus microparticles with tunable anisotropic particle geometry. Adv. Funct. Mater. 29, 1805392 (2019)

Kamperman, T., Van Loo, B., Gurian, M., et al.: On-the-fly exchangeable microfluidic nozzles for facile production of various monodisperse micromaterials. Lab Chip 19, 1977–1984 (2019)

Lewis, C.L., Choi, C.H., Lin, Y., et al.: Fabrication of uniform DNA-conjugated hydrogel microparticles via replica molding for facile nucleic acid hybridization assays. Anal. Chem. 82, 5851–5858 (2010)

Hayakawa, M., Onoe, H., Nagai, K.H., et al.: Complex-shaped three-dimensional multi-compartmental microparticles generated by diffusional and Marangoni microflows in centrifugally discharged droplets. Sci. Rep. 6, 1–9 (2016)

Anselmo, A.C., Xu, X., Buerkli, S., et al.: A heat-stable microparticle platform for oral micronutrient delivery. Sci. Transl. Med. 11, eaaw3680 (2019)

Zhang, S., Zhou, S., Liu, H., et al.: Pinecone-inspired nanoarchitectured smart microcages enable nano/microparticle drug delivery. Adv. Funct. Mater. 30, 2002434 (2020)

Liu, D., Zhang, H., Fontana, F., et al.: Microfluidic-assisted fabrication of carriers for controlled drug delivery. Lab Chip 17, 1856–1883 (2017)

Liu, X., Yang, H., Liu, Y., et al.: Numerical study of clathrin-mediated endocytosis of nanoparticles by cells under tension. Acta Mech. Sin. 35, 691–701 (2019)

Geng, Y.H., Ge, X.H., Zhang, S.B., et al.: Microfluidic preparation of flexible micro-grippers with precise delivery function. Lab Chip 18, 1838–1843 (2018)

He, F., Zhang, M.J., Wang, W., et al.: Designable polymeric microparticles from droplet microfluidics for controlled drug release. Adv. Mater. Technol. 4, 1800687 (2019)

Herranz-Blanco, B., Arriaga, L.R., Makila, E., et al.: Microfluidic assembly of multistage porous silicon-lipid vesicles for controlled drug release. Lab Chip 14, 1083–1086 (2014)

Amstad, E., Kim, S.H., Weitz, D.A.: Photo- and thermoresponsive polymersomes for triggered release. Angew. Chem. Int. Ed. 51, 12499–12503 (2012)

Yin, W.S., Yates, M.Z.: Encapsulation and sustained release from biodegradable microcapsules made by emulsification/freeze drying and spray/freeze drying. J. Colloid Interface Sci. 336, 155–161 (2009)

Cheng, P., Wang, X., Feng, C.: Numerical simulation of phosphorus release from resuspended sediment. Acta Mech. Sin. 36, 1191–1201 (2020)

Lyu, J., Ruan, C., Zhang, X., et al.: Microparticle-assisted precipitation screening method for robust drug target identification. Anal. Chem. 92, 13912–13921 (2020)

Miyata, T., Jige, M., Nakaminami, T., et al.: Tumor marker-responsive behavior of gels prepared by biomolecular imprinting. Proc. Natl Acad. Sci. USA 103, 1190–1193 (2006)

Wu, S., Yang, Y., Jiang, H.: Thinning air–water films stabilized by bacterial particles. Acta Mech. Sin. (2021). https://doi.org/10.1007/s10409-020-01031-5

Song, J.K., Choi, H.J., Chin, I.: Preparation and properties of electrophoretic microcapsules for electronic paper. J. Microencapsul. 24, 11–19 (2007)

Nisisako, T., Torii, T., Takahashi, T., et al.: Synthesis of monodisperse bicolored Janus particles with electrical anisotropy using a microfluidic co-flow system. Adv. Mater. 18, 1152–1156 (2006)

Nisisako, T.: Recent advances in microfluidic production of Janus droplets and particles. Curr. Opin. Colloid Interface 25, 1–12 (2016)

Lan, Y., Yang, L., Zhang, M.C., et al.: Microreactor of Pd nanoparticles immobilized hollow microspheres for catalytic hydrodechlorination of chlorophenols in water. ACS Appl. Mater. Interfaces 2, 127–133 (2010)

Berkland, C., Kim, K.K., Pack, D.W.: Fabrication of PLG microspheres with precisely controlled and monodisperse size distributions. J. Control. Release 73, 59–74 (2001)

Berkland, C., King, M., Cox, A., et al.: Precise control of PLG microsphere size provides enhanced control of drug release rate. J. Control. Release 82, 137–147 (2002)

Chen, W.L., Palazzo, A., Hennink, W.E., et al.: Effect of particle size on drug loading and release kinetics of gefitinib-loaded PLGA microspheres. Mol. Pharm. 14, 459–467 (2017)

Qiu, J., Huo, D., Xue, J., et al.: Encapsulation of a phase-change material in nanocapsules with a well-defined hole in the wall for the controlled release of drugs. Angew. Chem. Int. Ed. 58, 10606–10611 (2019)

Windbergs, M., Zhao, Y., Heyman, J., et al.: Biodegradable core–shell carriers for simultaneous encapsulation of synergistic actives. J. Am. Chem. Soc. 135, 7933–7937 (2013)

Hyun, D.C., Lu, P., Choi, S.I., et al.: Microscale polymer bottles corked with a phase-change material for temperature-controlled release. Angew. Chem. Int. Ed. 125, 10662–10665 (2013)

Kong, T., Liu, Z., Song, Y., et al.: Engineering polymeric composite particles by emulsion-templating: thermodynamics versus kinetics. Soft Matter 9, 9780–9784 (2013)

Iwanaga, S., Saito, N., Sanae, H., et al.: Facile fabrication of uniform size-controlled microparticles and potentiality for tandem drug delivery system of micro/nanoparticles. Colloids Surf. B 109, 301–306 (2013)

Hwang, Y.K., Jeong, U., Cho, E.C.: Production of uniform-sized polymer core–shell microcapsules by coaxial electrospraying. Langmuir 24, 2446–2451 (2008)

Zhang, L., Huang, J., Si, T., et al.: Coaxial electrospray of microparticles and nanoparticles for biomedical applications. Expert Rev. Med. Devices 9, 595–612 (2012)

Shenoy, R., Tibbitt, M.W., Anseth, K.S., et al.: Formation of core–shell particles by interfacial radical polymerization initiated by a glucose oxidase-mediated redox system. Chem. Mater. 25, 761–767 (2013)

Dragosavac, M.M., Vladisavljević, G.T., Holdich, R.G., et al.: Production of porous silica microparticles by membrane emulsification. Langmuir 28, 134–143 (2012)

Wu, H., Ren, Y.K., Hou, L.K., et al.: Fabrication of syntactic foam fillers via manipulation of on-chip quasi concentric nanoparticle-shelled droplet templates. Lab Chip 20, 4600–4610 (2020)

Huang, F., Zhu, Z., Niu, Y., et al.: Coaxial oblique interface shearing: tunable generation and sorting of double emulsions for spatial gradient drug release. Lab Chip 20, 1249–1258 (2020)

Mu, K., Ding, H., Si, T.: Experimental and numerical investigations on interface coupling of coaxial liquid jets in co-flow focusing. Phys. Fluids 32, 042103 (2020)

Jiang, T., Jia, Y., Sun, H., et al.: Dielectrophoresis response of water-in-oil-in-water double emulsion droplets with singular or dual cores. Micromachines 11, 1121 (2020)

Pang, Y., Wang, X., Liu, Z.: Study of droplet flow in a T-shape microchannel with bottom wall fluctuation. Acta Mech. Sin. 34, 632–643 (2018)

Chen, P.W., Erb, R.M., Studart, A.R.: Designer polymer-based microcapsules made using microfluidics. Langmuir 28, 144–152 (2012)

Kim, J.W., Utada, A.S., Fernandez-Nieves, A., et al.: Fabrication of monodisperse gel shells and functional microgels in microfluidic devices. Angew. Chem. Int. Ed. 119, 1851–18554 (2007)

Al Nuumani, R., Bolognesi, G., Vladisavljević, G.T.: Microfluidic production of poly(1,6-hexanediol diacrylate)-based polymer microspheres and bifunctional microcapsules with embedded TiO2 nanoparticles. Langmuir 34, 11822–11831 (2018)

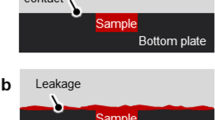

Wang, W., Zhang, M.J., Xie, R., et al.: Hole–shell microparticles from controllably evolved double emulsions. Angew. Chem. Int. Ed. 52, 8084–8087 (2013)

Ekanem, E.E., Zhang, Z.L., Vladisavljevic, G.T.: Facile microfluidic production of composite polymer core–shell microcapsules and crescent-shaped microparticles. J. Colloid Interface Sci. 498, 387–394 (2017)

Kim, D.Y., Jin, S.H., Jeong, S.G., et al.: Microfluidic preparation of monodisperse polymeric microspheres coated with silica nanoparticles. Sci. Rep. 8, 1–11 (2018)

Jo, Y.K., Lee, D.: Biopolymer microparticles prepared by microfluidics for biomedical applications. Small 16, 1903736 (2020)

Lone, S., Kim, S.H., Nam, S.W., et al.: Microfluidic preparation of dual stimuli-responsive microparticles and light-directed clustering. Langmuir 26, 17975–17980 (2010)

Ren, M., Guo, W., Guo, H., et al.: Microfluidic fabrication of bubble-propelled micromotors for wastewater treatment. ACS Appl. Mater. Interfaces 11, 22761–22767 (2019)

Yin, S.N., Wang, C.F., Yu, Z.Y., et al.: Versatile bifunctional magnetic-fluorescent responsive Janus supraballs towards the flexible bead display. Adv. Mater. 23, 2915–2919 (2011)

Kim, S.-H., Kim, J.W., Kim, D.-H., et al.: Enhanced-throughput production of polymersomes using a parallelized capillary microfluidic device. Microfluid. Nanofluid. 14, 509–514 (2013)

Oesterle, A.: Pipette Cookbook 2018: P-97 & P-1000 Micropipette Pullers. Sutter Instrument, Novato (2015)

Nisisako, T., Hatsuzawa, T.: A microfluidic cross-flowing emulsion generator for producing biphasic droplets and anisotropically shaped polymer particles. Microfluid. Nanofluid. 9, 427–437 (2009)

Chu, L.Y., Utada, A.S., Shah, R.K., et al.: Controllable monodisperse multiple emulsions. Angew. Chem. Int. Ed. 119, 9128–9132 (2007)

Nabavi, S.A., Vladisavljević, G.T., Gu, S., et al.: Double emulsion production in glass capillary microfluidic device: parametric investigation of droplet generation behaviour. Chem. Eng. Sci. 130, 183–196 (2015)

Utada, A.S., Lorenceau, E., Link, D.R., et al.: Monodisperse double emulsions generated from a microcapillary device. Science 308, 537–541 (2005)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grants 11832017, 11772343, and 12072350), the Chinese Academy of Sciences Key Research Program of Frontier Sciences (Grant QYZDB-SSW-JSC036), the Chinese Academy of Sciences Strategic Priority Research Program (Grant XDB22040403), and the Beijing Institute of Technology Research Fund Program for Young Scholars.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Executive Editor: Hong-Yuan Jiang

Supplementary Information

Below is the link to the electronic supplementary material.

(AVI 6437 kb)

(AVI 7564 kb)

(AVI 5010 kb)

(AVI 10015 kb)

Rights and permissions

About this article

Cite this article

Wang, D., Zheng, X., Chen, X. et al. Flow-pattern-altered syntheses of core–shell and hole–shell microparticles in an axisymmetric microfluidic device. Acta Mech. Sin. 37, 1378–1386 (2021). https://doi.org/10.1007/s10409-021-01096-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-021-01096-w