Abstract

The objective of this paper is to experimentally investigate the cavitation patterns and corresponding hydrodynamics of the hydrofoil with leading edge roughness. The aims are to (1) understand the effect of the leading edge roughness on the hydrodynamic performance, and (2) have a good knowledge of the interaction between the leading edge roughness and the cavitation patterns. Experimental results are indicated for the NACA 66 hydrofoils with and without leading edge roughness at different incidence angles for sub and cavitation conditions. The experiments are conducted in the EPFL high-speed cavitation tunnel (Avellan 2015). The results showed that the leading edge roughness has a significant effect on the hydrodynamic performance at the sub cavitation, suppressing the formation of the incipient cavitation. The lift coefficient of the hydrofoil without leading edge roughness is larger than that of the hydrofoil with leading edge roughness, while for the drag coefficients, the results are contrary for the lift coefficient, and the maximum lift-to-drag ratio angle is delayed for the hydrofoil with leading edge roughness. The leading edge roughness modified the local pressure distribution at the leading edge region, which in turn significantly increased the minimum pressure coefficient, hence the incipient cavitation number of the hydrofoil with leading edge roughness. The formation and evolution of the transient cavity for the cloud cavitation is little affected by the leading edge roughness.

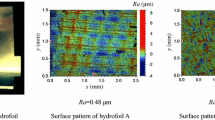

Graphic abstract

The re-entrant jet begins to form at the rear end of the cavity, due to the high reverse pressure gradient and moves toward the leading edge of the hydrofoil, then the cloud cavity gets organized by high vapor fraction and is lifted away from the surface, in which the cavity height (Δh) is larger than the roughness (Ra) and also, there is a distance between the leading edge roughness and re-entrant jet (Δs). Hence the leading edge roughness has a great effect on the leading edge local pressure distribution for the formation of incipient cavitation, while it is inessential for the evolution of the cloud cavitation.

Similar content being viewed by others

Abbreviations

- u :

-

Inflow velocity [m/s]

- b :

-

Span lengths [m]

- c :

-

Mean chord [m]

- h :

-

Roughness [m]

- Δh :

-

Cavity height [m]

- Δs :

-

Distance between roughness and re-entrant jet [m]

- v :

-

Fluid kinematic viscosity [m2/s]

- Re :

-

Reynolds number, Re = uc/v

- ρ :

-

Fluid density [kg/m3]

- α :

-

Hydrofoil geometry incidence relative to freestream flow (incidence angle)

- α e :

-

Maximum lift-to-drag ratio angle

- α cr :

-

Stall angle

- α 0 :

-

Zero-lift angle

- σ :

-

Cavitation number

- σ i :

-

Incipient cavitation number

- P ∞ :

-

Fluid static pressure [Pa]

- P v :

-

Saturated vapor pressure [Pa]

- C l :

-

Lift coefficient

- C d :

-

Drag coefficient

- C m :

-

Moment coefficient

- L :

-

Hydrodynamic lift [N]

- D :

-

Hydrodynamic drag [N]

- M :

-

Hydrodynamic moment [N]

- K :

-

Lift-to-drag ratio

- C p,min :

-

Minimum pressure coefficient

- P i :

-

Minimum surface pressure at leading edge region [Pa]

References

Ji, B., Bai, X.R., Zhu, Y., et al.: A review of the fundamental investigations of cavitation in hydraulic machinery. Chin J Hydrodyn. 32, 542–550 (2017)

Leclercq, C., Archer, A., Fortes-Patella, R., et al.: Numerical cavitation intensity on a hydrofoil for 3D homogeneous unsteady viscous flows. Int J Fluid Mach Syst. 10, 254–263 (2017). https://doi.org/10.5293/IJFMS.2017.10.3.254

Brennen, C.E.: Cavitation and bubble dynamics homogeneous bubbly flows, pp. 145–181. Cambridge University Press, London (2013)

Wu, Q., Huang, B., Wang, G.Y., et al.: Experimental and numerical investigation of hydroelastic response of a flexible hydrofoil in cavitating flow. Int. J. Multiph. Flow 74, 19–33 (2015). https://doi.org/10.1016/j.ijmultiphaseflow.2015.03.023

Akbarzadeh, P., Akbarzadeh, E.: Hydrodynamic characteristics of blowing and suction on sheet-cavitating flows around hydrofoils. Ocean Eng. 114, 25–36 (2016). https://doi.org/10.1016/j.oceaneng.2016.01.015

Joy, J.A., Mathaiyan, V., Sajjad, M., et al.: Numerical studies on cavitation and surface roughness//key engineering materials. Trans Tech Publications Ltd. 793, 79–84 (2019)

Coutier-Delgosha, O., Devillers, J.F., Leriche, M., et al.: Effect of wall roughness on the dynamics of unsteady cavitation. J. Fluids Eng. 127, 726–733 (2005). https://doi.org/10.1115/1.1949637

Nie, M.X.: Cavitation prevention with roughened surface. J. Hydr. Eng. 127, 878–880 (2001). https://doi.org/10.1061/(ASCE)0733-9429(2001)127:10(878)

Huang, X., Zhang, M.D., Fu, X.N.: Experimental study of coatings’ effect on cavitating flow. J. Ship Mech. 19, 35–42 (2015). https://doi.org/10.3969/j.issn.1007-7294.2015.h1.004

Arndt, R.E.A., Ippen, A.T.: Rough surface effects on cavitation inception. J. Basic Eng. 90, 249 (1968). https://doi.org/10.1115/1.3605086

Billet, M.L., Holl, J.W., Parkin, B.R.: Scale effects on cavitating flows due to surface roughness and laminar separation. AIAA J. 20, 632–637 (1982). https://doi.org/10.2514/3.7935

Franc, J.P., Michel, J.M.: Fundamentals of cavitation. Fluid Mech. Appl. 76 (2005)

Knapp, R.T., Daily, J.W., Hammitt, F.G.: Cavitation. McGraw-Hill (1970)

Esfahanian, V., Akbarzadeh, P.: Numerical investigation on a new local preconditioning method for solving the incompressible inviscid, non-cavitating and cavitating flows. J. Franklin Inst. 348, 1208–1230 (2011). https://doi.org/10.1016/j.jfranklin.2010.01.008

Wu, Q., Wang, C.C., Huang, B., et al.: Measurement and prediction of cavitating flow-induced vibrations. Journal of Hydrodynamic. 30, 1064–1071 (2018). https://doi.org/10.1007/s42241-018-0115-5

Iyer, C.O., Ceccio, S.L.: The influence of developed cavitation on the flow of a turbulent shear layer. Phys. Fluids 14, 3414–3431 (2002). https://doi.org/10.1063/1.1501541

Huang, B., Qiu, S.C., Li, X.B., et al.: A review of transient flow structure and unsteady mechanism of cavitating flow. J. Hydrodyn. 31, 429–444 (2019). https://doi.org/10.1007/s42241-019-0050-0

Franc, J.P., Michel, J.M.: Unsteady attached cavitation on an oscillating hydrofoil. J. Fluid Mech. 193, 171–189 (1988). https://doi.org/10.1017/S0022112088002101

Amromin, E.: Development and validation of computational fluid dynamics models for initial stages of cavitation. J. Fluids Eng. 136, 081–303 (2014). https://doi.org/10.1115/1.4026883

Arakeri, V.H., Acosta, A.J.: Viscous effects in the inception of cavitation on axisymmetric bodies. J. Fluids Eng. (1973). https://doi.org/10.1115/1.3447065

Foeth, E.J., Van, D.C.W.H., Van, T.T., et al.: Time resolved PIV and flow visualization of 3D sheet cavitation. Exp. Fluids 40, 503–513 (2006). https://doi.org/10.1007/s00348-005-0082-9

Esfahanian, V., Akbarzadeh, P., Hejranfar, K.: An improved progressive preconditioning method for steady non-cavitating and sheet-cavitating flows. Int. J. Numer. Meth. Fluids 68, 210–232 (2012). https://doi.org/10.1002/fld.2502

Rasthofer, U., Wermelinger, F., Hadijdoukas, P., et al.: Large scale simulation of cloud cavitation collapse. Procedia Comput. Sci. 108, 1763–1772 (2017). https://doi.org/10.1016/j.procs.2017.05.158

Stutz, B., Reboud, J.L.: Two-phase flow structure of sheet cavitation. Phys. Fluids 9, 3678–3686 (1997). https://doi.org/10.1063/1.869505

Li, X.B., Wang, G.Y., Zhang, M.D., et al.: Structures of supercavitating multiphase flows. Int. J. Therm. Sci. 47, 1263–1275 (2008). https://doi.org/10.1016/j.ijthermalsci.2007.11.010

Katz, J.: Cavitation phenomena within regions of flow separation. J. Fluid Mech. 140, 397–436 (1984). https://doi.org/10.1017/S0022112084000665

Shen, Y.T., Peterson, F.B.: Unsteady cavitation on an oscillating hydrofoil. In: Proceedings of the 12th Symposium on Naval Hydrodynamics, National Academy of Sciences, Washington, D.C. (1978)

Shen, Y.T., Peterson, F. B.: The influence of hydrofoil oscillation on boundary layer transition and cavitation noise. In: Proceedings of the 13th Symposium on Naval Hydrodynamics, Shipbuilding Research Association of Japan Tokyo, Japan (1980)

Hart, D.P., Brennen, C.E., Acosta, A.J.: Observations of cavitation on a three-dimensional oscillating hydrofoil. In: Proceedings of the 25th Cavitation and Multiphase Flow Forum, Toronto, Ontario, 49–52 (1990)

Knapp, R.T.: Recent investigations of the mechanics of cavitation and cavitation damage. J. Tribol. Trans. ASME. 77, 1045–1054 (1955)

Huang, B., Zhao, Y., Wang, G.Y.: Large eddy simulation of turbulent vortex-cavitation interactions in transient sheet/cloud cavitating flows. Comput. Fluids 92, 113–124 (2014). https://doi.org/10.1016/j.compfluid.2013.12.024

Wu, Q., Huang, B., Wang, G.Y., et al.: The transient characteristics of cloud cavitating flow over a flexible hydrofoil. Int. J. Multiph. Flow 99, 162–173 (2018). https://doi.org/10.1016/j.ijmultiphaseflow.2017.10.006

Wu, Q., Wang, C.C., Huang, B., et al.: Measurement and prediction of cavitating flow-induced vibrations. J. Hydrodyn. 30, 1064–1071 (2018). https://doi.org/10.1007/s42241-018-0115-5

Ji, B., Luo, X.W., Arndt, R.E.A., et al.: Large eddy simulation and theoretical investigations of the transient cavitating vortical flow structure around a NACA 66 hydrofoil. Int. J. Multiph. Flow 68, 121–134 (2015). https://doi.org/10.1016/j.ijmultiphaseflow.2014.10.008

Ji, B., Long, Y., Long, X.P., et al.: Large eddy simulation of turbulent attached cavitating flow with special emphasis on large scale structures of the hydrofoil wake and turbulence-cavita-tion interactions. J. Hydrodyn. 29, 27–39 (2017). https://doi.org/10.1016/S1001-6058(16)60715-1

De La Torre, O., Escaler, X., Egusquiza, E., et al.: Experimental investigation of added mass effects on a hydrofoil under cavitation conditions. J. Fluids Struct. 39, 173–187 (2013). https://doi.org/10.1016/j.jfluidstructs.2013.01.008

Asnaghi, A., Svennberg, U., Gustafsson, R., et al.: Roughness effects on the tip vortex strength and cavitation inception. In: Sixth International Symposium on Marine Propulsors, SMP19, Rome, Italy (2019)

Liang, C., He, K.J., Shuai, W.: Numerical investigation of diesel nozzle wall roughness effects on cavitation. Mach. Design Manuf. 8, 7 (2017). https://doi.org/10.19356/j.cnki.1001-3997.2017.08.006

Yao, Z.F., Yang, M., Xiao, R.F., et al.: Influence of wall roughness on the static performance and pressure fluctuation characteristics of a double-suction centrifugal pump. Proc. Inst. Mech. Eng A 232, 826–840 (2018). https://doi.org/10.1177/0957650918757246

Asnaghi, A., Svennberg, U., Gustafsson, R., et al.: Roughness effects on the tip vortex strength and cavitation inception. In: Sixth International Symposium on Marine Propulsors: SMP19, Rome, Italy (2019)

Echouchene, F., Belmabrouk, H., Le Penven, L., et al.: Numerical simulation of wall roughness effects in cavitating flow. Int. J. Heat Fluid Flow 32, 1068–1075 (2011). https://doi.org/10.1016/j.ijheatfluidflow.2011.05.010

Hao, J.F., Zhang, M.D., Huang, X.: The influence of surface roughness on cloud cavitation flow around hydrofoils. Acta. Mech. Sin. 34, 10–21 (2018). https://doi.org/10.1007/s10409-017-0689-0

Churkin, S.A., Pervunin, K.S., Kravtsova, A.Y., et al.: Cavitation on NACA 0015 hydrofoils with different wall roughness: high-speed visualization of the surface texture effects. J. Visual. 19, 587–590 (2016). https://doi.org/10.1007/s12650-016-0355-9

Zhang, Q., Lee, S.W., Ligrani, P.M.: Effects of surface roughness and freestream turbulence on the wake turbulence structure of a symmetric airfoil. Phys. Fluids 16, 2044–2053 (2004). https://doi.org/10.1063/1.1736676

Katz, J., Galdo, J.B.: Effect of roughness on rollup of tip vortices on a rectangular hydrofoil. J. Aircraft. 26, 247–253 (1989). https://doi.org/10.2514/3.45753

MacDonald, M., Hutchins, N., Chung, D.: Roughness effects in turbulent forced convection. J. Fluid Mech. 861, 138–162 (2019). https://doi.org/10.1017/jfm.2018.900

Di-Cicca, G.M., Morvan, P., Onorato, M.: Turbulence investigation in the roughness sub-layer of a near wall flow. Environ. Fluid Mech. 18, 1413–1433 (2018). https://doi.org/10.1007/s10652-018-9600-1

Lang, A.W., Bradshaw, M.T., Smith, J.A., et al.: Movable shark scales act as a passive dynamic micro-roughness to control flow separation. Bioinspir. Biomimet. 9, 036017 (2014). https://doi.org/10.1088/1748-3182/9/3/036017

Delafin, P.L., Deniset, F., Astolfi, J.A.: Effect of the laminar separation bubble induced transition on the hydrodynamic performance of a hydrofoil. Eur. J. Mech. 46, 190–200 (2014). https://doi.org/10.1016/j.euromechflu.2014.03.013

Ausoni, P., Farhat, M., Escaler, X., et al.: Cavitation influence on von Kármán vortex shedding and induced hydrofoil vibrations. J. Fluids Eng. 129, 966–973 (2007). https://doi.org/10.1115/1.2746907

Avellan, F., Henry, P., Rhyming, I.: A new high speed cavitation tunnel for cavitation studies in hydraulic machinery. Proc. Int. Cavit. Res. Facil. Techn. 57, 49–60 (1987)

Zobeiri, A.: Effect of hydrofoil trailing edge geometry on the wake dynamics. École Polytechnique Fédérale de Lausanne (2012). https://doi.org/10.5075/epfl-thesis-5218

Huang, B., Ducoin, A., Young, Y.L.: Physical and numerical investigation of cavitating flows around a pitching hydrofoil. Phys. Fluids 25, 102109 (2013). https://doi.org/10.1063/1.4825156

Dai, Y.J., Zhang, Y.Y., Huang, D.G.: Numerical study of the impact of hydrofoil surface roughness on cavitation suppression. J. Eng. Thermophys. 33, 770–773 (2012)

Acknowledgements

The authors gratefully acknowledge the great help of Dr. Mohamed Farhat (EPFL-LMH) and the support by the National Natural Science Foundation of China (Grant Nos: 51909002, 51839001, and 91752105), the Fundamental Research Funds for the Central Universities, and the Open Fund for Key Laboratory of Fluid and Power Machinery, Ministry of Education (Grant Nos: szjj2018-124 and szjj2019-024).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, Q., Liu, Y., Wu, Q. et al. Global cavitation patterns and corresponding hydrodynamics of the hydrofoil with leading edge roughness. Acta Mech. Sin. 36, 1202–1214 (2020). https://doi.org/10.1007/s10409-020-00992-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-020-00992-x