Abstract

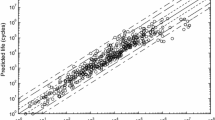

In this paper, ultrasonic (20 kHz) fatigue tests were performed on specimens of a high-strength steel in very high cycle fatigue (VHCF) regime. Experimental results showed that for most tested specimens failed in a VHCF regime, a fatigue crack originated from the interior of specimen with a fish-eye pattern, which contained a fine granular area (FGA) centered by an inclusion as the crack origin. Then, a two-parameter model is proposed to predict the fatigue life of high-strength steels with fish-eye mode failure in a VHCF regime, which takes into account the inclusion size and the FGA size. The model was verified by the data of present experiments and those in the literature. Furthermore, an analytic formula was obtained for estimating the equivalent crack growth rate within the FGA. The results also indicated that the stress intensity factor range at the front of the FGA varies within a small range, which is irrespective of stress amplitude and fatigue life.

(Graphical abstract)

A two-parameter model is proposed to predict the fatigue life of high-strength steels with fish-eye mode failure in a very high cycle fatigue regime, which takes into account the inclusion size and the FGA size. The model was verified by the data of present experiments and those inthe literature. Furthermore, an analytical formula was obtained for estimating the equivalent crack growth rate within FGA. It is also indicated that the stress intensity factor range at the front of the FGA varies within a small range, which is irrespective of stress amplitude and fatigue life. Figure Comparison of predicted fatigue life with experimental data, in which the superscript 4 denotes the specimens by oil-quenching and tempering for 2.5 h in a vacuum at \(300\,^\circ \hbox {C}\) by a conventional frequency test.

Similar content being viewed by others

References

Bathias, C., Drouillac, L., Le Francois, P.: How and why the fatigue \(S\)-\(N\) curve does not approach a horizontal asymptote. Int. J. Fatigue 23, S143–151 (2001)

Hong, Y., Zhao, A., Qian, G.: Essential characteristic and influential factors for very-high-cycle fatigue behavior of metallic materials. Acta Metall. Sin. 45, 769–780 (2009)

Duan, Z., Ma, X.F., Shi, H.J., et al.: Gigacycle fatigue behaviors of two SNCM439 steels with different tensile strengths. Acta Mech. Sin. 27, 778–784 (2011)

Huang, Z.Y., Wang, Q.Y., Wagner, D., et al.: A rapid scatter prediction method for very high cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 36, 462–468 (2013)

Murakami, Y., Matsunaga, H., Abyazi, A., et al.: Defect size dependence on threshold stress intensity for high-strength steel with internal hydrogen. Fatigue Fract. Eng. Mater. Struct. 36, 836–850 (2013)

Lei, Z., Xie, J., Sun, C., et al.: Effect of loading condition on very-high-cycle fatigue behavior and dominant variable analysis. Sci. China-Phys. Mech. Astron. 57, 74–82 (2014)

Sun, C., Lei, Z., Hong, Y.: Effects of stress ratio on crack growth rate and fatigue strength for high cycle and very-high-cycle fatigue of metallic materials. Mech. Mater. 69, 227–236 (2014)

Li, S.X., Zhang, P.Y., Yu, S.R.: Experimental study on very high cycle fatigue of martensitic steel of 2Cr13 under corrosive environment. Fatigue Fract. Eng. Mater. Struct. 37, 1146–1152 (2014)

Shanyavskiy, A.A.: Very-high-cycle-fatigue of in-service air-engine blades, compressor and turbine. Sci. China-Phys. Mech. Astron. 57, 19–29 (2014)

Shyam, A., Blau, P., Jordan, T., et al.: Effect of submillimeter size holes on the fatigue limit of a high strength tool steel. Fatigue Fract. Eng. Mater. Struct. 37, 368–379 (2014)

Liu, X., Sun, C., Hong, Y.: Effects of stress ratio on high cycle and very-high-cycle fatigue behavior of a Ti-6Al-4V alloy. Mater. Sci. Eng. 622, 228–235 (2015)

Sakai, T., Sato, Y., Oguma, N., et al.: Characteristic \(S\)–\(N\) properties of high-carbon-chromium-bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. Mater. Struct. 25, 765–773 (2002)

Murakami, Y., Nomoto, T., Ueda, T.: Factors influencing the mechanism of superlong fatigue failure in steels. Fatigue Fract. Eng. Mater. Struct. 22, 581–590 (1999)

Shiozawa, K., Lu, L., Ishihara, S., et al.: \(S\)–\(N\) curve characteristics and subsurface crack initiation behaviour in ultra-long life fatigue of a high carbon-chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 24, 781–790 (2001)

Murakami, Y., Nomoto, T., Ueda, T.: On the mechanism of fatigue failure in the superlong life regime (\(N {\>} 10^{7}\) cycles). Part I: influence of hydrogen trapped by inclusions. Fatigue Fract. Eng. Mater. Struct. 23, 893–902 (2000)

Zhao, A., Xie, J., Sun, C., et al.: Prediction of threshold value for FGA formation. Mater. Sci. Eng. A 528, 6872–6877 (2011)

Tanaka, K., Akiniwa, Y.: Fatigue crack propagation behaviour derived from \(S\)–\(N\) data in very high cycle regime. Fatigue Fract. Eng. Mater. Struct. 25, 775–784 (2002)

Pippan, R., Tabernig, B., Gach, E., et al.: Non-propagation conditions for fatigue cracks and fatigue in the very high-cycle regime. Fatigue Fract. Eng. Mater. Struct. 25, 805–811 (2002)

Ogawa, T., Stanzl-Tschegg, S.E., Schönbauer, B.M., et al.: A fracture mechanics approach to interior fatigue crack growth in the very high cycle regime. Eng. Fract. Mech. 115, 241–254 (2014)

Sander, M., Müller, T., Lebahn, J., et al.: Influence of mean stress and variable amplitude loading on the fatigue behaviour of a high-strength steel in VHCF regime. Int. J. Fatigue 62, 10–20 (2014)

Chapetti, M.D., Tagawa, T., Miyata, T.: Ultra-long cycle fatigue of high-strength carbon steels part I: review and analysis of the mechanism of failure. Mater. Sci. Eng. A 356, 227–235 (2003)

Shiozawa, K., Morii, Y., Nishino, S., et al.: Subsurface crack initiation and propagation mechanism in high strength steel in a very high cycle fatigue regime. Int. J. Fatigue 28, 1521–1532 (2006)

Wagner, D., Ranc, N., Bathias, C., et al.: Fatigue crack initiation detection by an infrared thermography method. Fatigue Fract. Eng. Mater. Struct. 33, 12–21 (2009)

Li, W., Sakai, T., Li, Q., et al.: Reliability evaluation on very high cycle fatigue property of GCr15 bearing steel. Int. J. Fatigue 32, 1096–1107 (2010)

Hong, Y., Lei, Z., Sun, C., et al.: Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 58, 144–151 (2014)

Liu, Y.B., Li, Y.D., Li, S.X., et al.: Prediction of the \(S\)–\(N\) curves of high-strength steels in the very high cycle fatigue regime. Int. J. Fatigue 32, 1351–1357 (2010)

Sun, C., Xie, J., Zhao, A., et al.: A cumulative damage model for fatigue life estimation of high-strength steels in high-cycle and very-high-cycle fatigue regimes. Fatigue Fract. Eng. Mater. Struct. 35, 638–647 (2012)

Sun, C., Lei, Z., Xie, J., et al.: Effects of inclusion size and stress ratio on fatigue strength for high-strength steels with fish-eye mode failure. Int. J. Fatigue 48, 19–27 (2013)

Wang, Q.Y., Bathias, C., Kawagoishi, N., et al.: Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength. Int. J. Fatigue 24, 1269–1274 (2002)

Murakami, Y., Endo, M.: Effects of defects, inclusions and inhomogeneities on fatigue strength. Int. J. Fatigue 16, 163–182 (1994)

Akiniwa, Y., Miyamoto, N., Tsuru, H., et al.: Notch effect on fatigue strength reduction of bearing steel in the very high cycle regime. Int. J. Fatigue 28, 1555–1565 (2006)

Tanaka, K., Mura, T.: A theory of fatigue crack initiation at inclusions. Metall. Trans. A 13A, 117–123 (1982)

Yang, Z.G., Li, S.X., Liu, Y.B., et al.: Estimation of the size of GBF area on fracture surface for high strength steels in very high cycle fatigue regime. Int. J. Fatigue 30, 1016–1023 (2008)

Hong, Y.S., Zhao, A.G., Qian, G.A., et al.: Fatigue strength and crack initiation mechanism of very-high-cycle fatigue for low alloy steels. Metall. Mater. Trans. A 43, 2753–2762 (2012)

Li, Y.D., Yang, Z.G., Li, S.X., et al.: Correlations between very high cycle fatigue properties and inclusions of GCr15 bearing Steel. Acta Metall. Sin. 44, 968–972 (2008)

Frost, N.E., Dugdale, D.S.: The propagation of fatigue cracks in sheet specimens. J. Mech. Phys. Solids 6, 92–110 (1958)

Jones, R., Molent, L., Pitt, S.: Similitude and the Paris crack growth law. Int. J. Fatigue 30, 1873–1880 (2008)

Atkinson, H.V., Shi, G.: Characterization of inclusions in clean steels: a review including the statistics of extremes methods. Prog. Mater. Sci. 48, 457–520 (2003)

Nakajima, M., Tokaji, K., Itoga, H., et al.: Effect of loading condition on very high cycle fatigue behavior in a high strength steel. Int. J. Fatigue 32, 475–480 (2010)

Sakai, T.: Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use. J. Solid Mech. Mater. Eng. 3, 425–439 (2009)

Paris, P.C., Marines-Garcia, I., Hertzberg, R.W., et al.: The relationship of effective stress intensity, elastic modulus and Burgers-vector on fatigue crack growth as associated with “fish eye” gigacycle fatigue phenomena. In: Proceedings of the international conference on very high cycle fatigue III, Kyoto (2004)

Marines-Garcia, I., Paris, P.C., Tada, H., et al.: Fatigue crack growth from small to large cracks on very high cycle fatigue with fish-eye failures. Eng. Fract. Mech. 75, 1657–1665 (2008)

Acknowledgments

This project was supported by the National Basic Research Program of China (Grant 2012CB937500) and the National Natural Science Foundations of China (Grants 11172304 and 11202210).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Liu, X. & Hong, Y. A two-parameter model to predict fatigue life of high-strength steels in a very high cycle fatigue regime. Acta Mech Sin 31, 383–391 (2015). https://doi.org/10.1007/s10409-015-0451-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-015-0451-4