Abstract

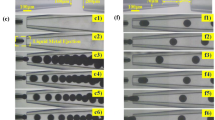

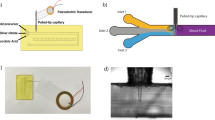

The monodisperse magnetic liquid metal droplets have been proven to be very important in soft robots or machines and flexible electronics. Unfortunately, the size and composition tunability is technically confined due to the scarce of the preparation method. This paper reports a 3D-printed coaxial microfluidic device to generate monodisperse magnetic liquid metal droplets (MLMDs) with droplets sizes varied in a large range of 650 to 1900 μm. Owing to the inner-dispersed iron/nickel (Fe/Ni) particles, the MLMDs with different magnetic contents possess unique magnetic field manipulation performance. The minimum magnetic flux density driven the MLMDs is only 24 mT and the relative average actuating velocity reaches as high as 5.1 cm/s, which means that the MLMDs can be precisely and rapidly manipulated. In addition, the manipulation of the MLMDs by an external magnetic field has been illustrated in two-dimensional crooked channels and three-dimensional spiral channels. The MLMDs move through the two kinds of channels smoothly and exhibit good magnetic maneuverability. Finally, the potential feasibility of the MLMDs is further confirmed in small-sized electrical switches with the sequential turning on of light-emitting diodes (LEDs).

Similar content being viewed by others

References

Ahmed A, Qureshi AJ, Fleck BA, Waghmare PR (2018) Effects of magnetic field on the spreading dynamics of an impinging ferrofluid droplet. J Colloid Interface Sci 532:309–320

Bartlett MD, Kazem N, Powell-Palm MJ, Huang XN, Sun WH, Malen JA, Majidi C (2017) High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proc Nat Acad Sci USA 114:2143–2148

Bhattacharjee N, Urrios A, Kanga S, Folch A (2016) The upcoming 3D-printing revolution in microfluidics. Lab Chip 16:1720–1742

Bilodeau RA, Zemlyanov DY, Kramer RK (2017) Liquid metal switches for environmentally responsive electronics. Adv Mater Interfaces 4:1600913

Chu K, Song BG, Yang HI, Kim DM, Lee CS, Park M, Chung CM (2018) Smart passivation materials with a liquid metal microcapsule as self-healing conductors for sustainable and flexible perovskite solar cells. Adv Funct Mater 28:1800110

Dickey MD (2014) Emerging applications of liquid metals featuring surface oxides. ACS Appl Mat Inter 6:18369–18379

Fang F, Ran SY, Fang ZP, Song PG, Wang H (2019a) Improved flame resistance and thermo-mechanical properties of epoxy resin nanocomposites from functionalized graphene oxide via self-assembly in water. Composites Part B-Eng 165:406–416

Fang QL, Zhang JF, Bai LF, Duan JY, Xu HJ, Leung KCF, Xuan SH (2019b) In situ redox-oxidation polymerization for magnetic core-shell nanostructure with polydopamine-encapsulated-Au hybrid shell. J Hazard Mater 367:15–25

Gu Y, Kojima H, Miki N (2011) Theoretical analysis of 3D emulsion droplet generation by a device using coaxial glass tubes. Sens Actuators Physic 169:326–332

Hu L, Wang HZ, Wang XF, Liu X, Guo JR, Liu J (2019) Magnetic liquid metals manipulated in the three-dimensional free space. ACS Appl Mat Inter 11:8685–8692

Hu T, Xuan SH, Ding L, Gong XL (2018) Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater Des 156:528–537

Hutter T, Bauer WAC, Elliott SR, Huck WTS (2012) Formation of spherical and non-spherical eutectic gallium-indium liquid-metal microdroplets in microfluidic channels at room temperature. Adv Funct Mater 22:2624–2631

Ilyas N, Cook A, Tabor CE (2017) Designing liquid metal interfaces to enable next generation flexible and reconfigurable electronics. Adv Mater Interfaces 4:1700141

Jeon J, Lee JB, Chung SK, Kim D (2016) Magnetic liquid metal marble: characterization of lyophobicity and magnetic manipulation for switching applications. J Microelectromech Syst 25:1050–1057

Jeon J, Lee JB, Chung SK, Kim D (2017) On-demand magnetic manipulation of liquid metal in microfluidic channels for electrical switching applications. Lab Chip 17:128–133

Jeong J, Lee JB, Chung SK, Kim D (2019) Electromagnetic three dimensional liquid metal manipulation. Lab Chip 19:3261–3267

Ji QL, Zhang JM, Liu Y, Li XY, Lv PY, Jin DP, Duan HL (2018) A modular microfluidic device via multimaterial 3D printing for emulsion generation. Sci Rep 8:4791

Jin TM, Hadji EM, Zhao N, Duan ZY, Wang JT (2019) Generation and analysis of axiolitic liquid-metal droplets in a T-Junction microfluidic device. Chemistryselect 4:3926–3935

Khoshmanesh K, Tang SY, Zhu JY, Schaefer S, Mitchell A, Kalantar-Zadeh K, Dickey MD (2017) Liquid metal enabled microfluidics. Lab Chip 17:974–993

Lee CY, Lin YH, Lee GB (2009) A droplet-based microfluidic system capable of droplet formation and manipulation. Microfluid Nanofluid 6:599–610

Lee JM, Zhang M, Yeong WY (2016a) Characterization and evaluation of 3D printed microfluidic chip for cell processing. Microfluid Nanofluid 20:5

Lee S, Kim H, Won DJ, Lee J, Kim J (2016b) On-demand, parallel droplet merging method with non-contact droplet pairing in droplet-based microfluidics. Microfluid Nanofluid 20:1

Lei Q, Zheng C, He F, Zhao J, Liu Y, Zhao XP, Yin JB (2018) Enhancing electroresponsive electrorheological effect and temperature dependence of poly(ionic liquid) particles by hard core confinement. Langmuir 34:15827–15838

Li FX, Kuang SL, Li XP, Shu J, Li WH, Tang SY, Zhang SW (2019) Magnetically- and electrically-controllable functional liquid metal droplets. Adv Mater Technol 4:1800694

Liu TY, Sen P, Kim CJCJ (2012) Characterization of nontoxic liquid-metal alloy galinstan for applications in microdevices. J Microelectromech Syst 21:443–450

Ma B, Xu CT, Chi JJ, Chen J, Zhao C, Liu H (2019) A versatile approach for direct patterning of liquid metal using magnetic field. Adv Funct Mater 29:1901370

Morimoto Y, Kiyosawa M, Takeuchi S (2018) Three-dimensional printed microfluidic modules for design changeable coaxial microfluidic devices. Sensors Actuators B-Chem 274:491–500

Morimoto Y, Tan WH, Takeuchi S (2009) Three-dimensional axisymmetric flow-focusing device using stereolithography. Biomed Microdevices 11:369–377

Nguyen TH, Chen XM, Sedighi A, Krull UJ, Ren CL (2018) A droplet-based microfluidic platform for rapid immobilization of quantum dots on individual magnetic microbeads. Microfluid Nanofluid 22:63

Shu J, Tang SY, Feng ZH, Li WH, Li XP, Zhang SW (2018) Unconventional locomotion of liquid metal droplets driven by magnetic fields. Soft Matter 14:7113–7118

Song R, Abbasi MS, Lee J (2019) Fabrication of 3D printed modular microfluidic system for generating and manipulating complex emulsion droplets. Microfluid Nanofluid 23:92

Tang SY, Joshipura ID, Lin YL, Kalantar-Zadeh K, Mitchell A, Khoshmanesh K, Dickey MD (2016) Liquid-metal microdroplets formed dynamically with electrical control of size and rate. Adv Mater 28:604–609

Tang SY et al (2014) Liquid metal enabled pump. Proc Nat Acad Sci USA 111:3304–3309

Tong Y, Dong XF, Qi M (2018) Improved tunable range of the field-induced storage modulus by using flower-like particles as the active phase of magnetorheological elastomers. Soft Matter 14:3504–3509

Wang XL, Guo R, Liu J (2019) Liquid metal based soft robotics: materials, designs, and applications. Adv Mater Technol 4:1800549

Wu J, Tang SY, Fang T, Li WH, Li XP, Zhang SW (2018) A wheeled robot driven by a liquid-metal droplet. Adv Mater 30:1805039

Yazdi AA, Popma A, Wong W, Nguyen T, Pan YY, Xu J (2016) 3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications. Microfluid Nanofluid 20:50

Zhang J, Guo R, Liu J (2016) Self-propelled liquid metal motors steered by a magnetic or electrical field for drug delivery. J Mater Chem B 4:5349–5357

Zhou ZY, Kong TT, Mkaouar H, Salama KN, Zhang JM (2018) A hybrid modular microfluidic device for emulsion generation. Sensors Actuators Physic 280:422–428

Acknowledgements

Financial support from the National Natural Science Foundation of China (Grant Nos. 11822209), and the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDB22040502) are gratefully acknowledged. This study was also supported by the Collaborative Innovation Center of Suzhou Nano Science and Technology, Joint Fund of USTC-National Synchrotron Radiation Laboratory (KY2090000055). Thanks to the instrumentation support from engineering practice center of USTC.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 2092 kb)

Supplementary file2 (MP4 6173 kb)

Supplementary file3 (MP4 5331 kb)

Rights and permissions

About this article

Cite this article

He, X., Wu, J., Hu, T. et al. A 3D-printed coaxial microfluidic device approach for generating magnetic liquid metal droplets with large size controllability. Microfluid Nanofluid 24, 30 (2020). https://doi.org/10.1007/s10404-020-02336-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-020-02336-4