Abstract

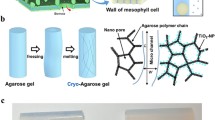

In land plants, water vapor diffuses into the air through the stomata. The loss of water vapor creates a water potential difference between the leaf and the soil, which draws the water upward. Quantitatively, the water potential difference is 1–2 MPa which can support a water column of 100–200 m. Here we present the design and operation of a biomimetic micropump. The micropump is mainly composed of a 48-μm thick metal screen plate with a group of 102-μm diameter micropores and an agarose gel sheet with nanopores of 100 nm diameter. The micropores in the screen plate imitate the stomata to regulate the flow rate of the micropump. The agarose gel sheet is used to imitate the mesophyll cells around the stomata. The lost of water from the nanopores in the gel sheet can generate a water potential difference (more than 30 kPa) which can drive solution flow in a microfluidic chip. Results have shown that a precise flow rate of 4–8 nl/min can be obtained by using this micropump, and its ultra-high flow rate is 113–126 nl/min. The advantages of this biomimetic micropump include adjustable flow rate, simple structure and low fabrication cost. It can be used as a “plug and play” fluid-driven unit in microfluidic chips without any external power sources or equipments.

Similar content being viewed by others

References

Amirouche F, Zhou Y, Johnson T (2009) Current micropump technologies and their biomedical applications. Microsyst Technol 15(5):647–666

Bertarelli E, Corigliano A et al (2011) Design of high stroke electrostatic micropumps: a charge control approach with ring electrodes. Microsyst Technol 17:165–173

Chan S-C, Chen C-R, Liu C-H (2010) A bubble-activated micropump with high-frequency flow reversal. Sens Actuators A 163:501–509

Chia BT, Liao H-H, Yang Y-J (2011) A novel thermo-pneumatic peristaltic micropump with low temperature elevation on working fluid. Sens Actuators A 165:86–93

Darabi J, Rada M, Ohadi M, Lawler J (2002) Design, fabrication, and testing of an electrohydrodynamic ion drag micropump. J Microelectromech Syst 11(6):684–690

Du WB, Fang Q, He QH (2005) High throughput nanoliter sample introduction microfluidic chip-based flow-injection analysis system with gravity driven flows. Anal Chem 77:1330

Fang Y, Tan X (2010) A novel diaphragm micropump actuated by conjugated polymer petals: fabrication, modeling, and experimental results. Sens Actuators A 158:121–131

Goedecke N, Manz A (2002) Injection modes for evaporation driven continuous liquid flow. In: Baba Y (ed) Micro total analysis system. Kluwer Academic Publishers, Dordrecht, pp 166–167

Good BT, Bowman CN, Davis RH (2006) An effervescent reaction micropump for portable microfluidic systems. Lab Chip 6:659–666

Hacke UG, Sperry JS, Pockman WT, Davis SD (2001) Trends in wood density and structure are linked to prevention of xylem implosion by negative pressure. Oecologia 126:457–461

Hsu YC, Le NB (2009) Equivalent electrical network for performance characterization of piezoelectric peristaltic micropump. Microfluid Nanofluid 7(2):237–248

Iverson BD, Garimella SV (2008) Recent advances in microscale pumping technologies: a review and evaluation. Microfluidics Nanofluidics 5(2):145–174

Jang J, Lee SS (2000) Theoretical and experimental study of MHD (magnetohydrodynamic) micropump. Sens Actuators A 80(1):84–89

Juncker D, Schmid H, Drechsler U, Wolf M, Michel B et al (2002) Autonomous microfluidic capillary system. Anal Chem 74:6139–6144

Kim SH, Hashi S, Ishiyama K (2011) Centrifugal force based magnetic micro-pump driven by rotating magnetic fields. J Phys 266(1):012072

Koch GW, Sillett SC, Jennings GM, Davis SD (2004) The limits to tree height. Nature 428:851–854

Lazar IM, Karger BL (2002) Electroosmotic pumping system for microfluidic sample handling. Anal Chem 74(24):6259–6268

Li JM, Liu C, Qiao HC (2008) Hot embossing/bonding of a poly(ethylene terephthalate) (PET) microfluidic chip. J Micromech Microeng 18:015008

Maruo S, Takaura A, Saito Y (2009) Optically driven micropump with a twin spiral microrotor. Opt Express 17(21):18525–18532

Meng DD, Chang-Jin CJK (2008) Micropumping of liquid by directional growth and selective venting of gas bubbles. Lab Chip 8:958–968

Mercury L, Azaroual M, Zeyen H (2003) Thermodynamic properties of solutions in metastable systems under negative or positive pressures. Geochim Cosmochim Acta 67(10):1769–1785

Michele Holbrook N, Burns MJ, Field CB (1995) Negative xylem pressures in plants: a test of the balancing pressure. Techn Sci 270(5239):1193–1194

Nguyen NT, Meng AH, Black J, White RM (2000) Integrated flow sensor for in situ measurement and control of acoustic streaming in flexural plate wave micropumps. Sens Actuators A 79(2):115–121

Nilson SE, Assmann SM (2007) The control of transpiration: insights from Arabidopsis. Plant Physiol 143:19–27

Pickard WF (1981) The ascent of sap in plants. Prog Biophys Mol Biol 37:181–229

Poole PH, Sciortino F, Essmann U, Eugene Stanley H (1992) Phase behaviour of metastable water. Nature 360(26):324–328

Sperry JS, Tyree MT (1988) Mechanism of water stress-induced xylem embolism. Plant Physiol 88:581–587

Szabo N, Totzke C, Tributsch H (2008) Total internal reflectance-infrared structural studies on tensile water formation during evaporation from nanopores. J Phys Chem C 112:6313–6318

Tyree MT, Davis SD, Cochard H (1994) Biophysical perspectives of xylem evolution: Is there a tradeoff of hydraulic efficiency for vulnerability to dysfunction? IAWA J 15(4):335–360

Wang SS, Huang XY, Yang C (2010) Valveless micropump with acoustically featured pumping chamber. Microfluid Nanofluid 8(4):549–555

Woias P (2005) Micropumps—past, progress and future prospects. Sens Actuators B 105(1):28–38

Yang L-J, Yao T-J, Tai Y-C (2004) The marching velocity of the capillary meniscus in a microchannel. J Micromech Microeng 14:220–225

Yang Y-N, Hsiung S-K, Lee G-B (2009) A pneumatic micropump incorporated with a normally closed valve capable of generating a high pumping rate and a high back pressure. Microfluidics Nanofluidics 6(6):823–833

Zhang C, Xing D, Li Y (2007) Micropumps, microvalves, and micromixers within PCR microfluidic chips: advances and trends. Biotechnol Adv 25:483–514

Acknowledgments

This study is supported by Major Program of National Natural Science Foundation of China (20890024), Major State Basic Research Development Program of China (No. 2007CB714502), National Natural Science Foundation of China (91023017; 91023046) and China Postdoctoral Science Foundation (20100481237).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J.M., Liu, C., Zhang, K.P. et al. A micropump based on water potential difference in plants. Microfluid Nanofluid 11, 717–724 (2011). https://doi.org/10.1007/s10404-011-0837-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-011-0837-y