Abstract

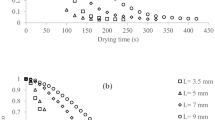

The effect of different infrared powers on drying of pear slices was investigated in an infrared dryer at 50-, 62-, 74-, and 88‑W infrared powers. The infrared radiation power affects the drying kinetics and quality of food products. As the infrared power increased, the drying time decreased, and the effective diffusivity coefficient increased. Seven different thin-layer drying models were evaluated for moisture ratios using nonlinear regression analysis. The results of regression analysis indicated that the model of Aghbashlo et al. is the best to describe drying behavior with the lowest P, χ2, RMSE and the highest R2 values. The Fick’s diffusion model was used to calculate the effective moisture diffusivity (Deff) of pear slices. The value of Deff varied from 9.43 × 10−10 to 2.58 × 10−9 m2/s. Activation energy was estimated by a modified Arrhenius type equation as 1.32 kW/kg.

Similar content being viewed by others

Change history

26 January 2023

In the PDF of this article, the volume number in the citation information was missing but it should have been "65". The original article PDF has now been corrected. The HTML is unaffected.

References

Aidani E, Hadadkhodaparast M, Kashaninejad M (2017) Experimental and modeling investigation of mass transfer during combined infrared-vacuum drying of Hayward kiwifruits. Food Sci Nutr 5:596–601

Al Juhaimi F, Uslu N, Ozcan MM, El Babiker EF, Ghafoor K (2016) Effect of drying on antioxidant activity, total phenol and mineral contents of pear fruits. Arch Lebensmittelhyg 67:164–167

Antal T (2017) Drying characteristics and quality of pear under hybrid drying (mid-infrared-freeze drying). Hungarian Agric Eng 31:33–44

Antal T, Tarek-Tilistyák J, Cziáky Z, Sinka L (2017) Comparison of drying and quality characteristics of pear (Pyrus communis L.) using mid-infrared-freeze drying and single stage of freeze drying. Int J Food Eng 2017:20160294

AOAC (1990) Official method of analysis. Association of Official Analytical Chemists, Arlington

Azizi D, Jafari SM, Mirzaei H, Dehnad D (2017) The Influence of refractance window drying on qualitative properties of kiwifruit slices. Int J Food Eng 13(2):20160201

Bakhshipour A, Zareiforoush H, Bagheri I (2021) Mathematical and intelligent modeling of stevia (Stevia rebaudiana) leaves drying in an infrared-assisted continuous hybrid solar dryer. Food Sci Nutr 9:532–543

Beigi M (2017) Thin layer drying of wormwood (Artemisia absinthium L.) leaves: Dehydration characteristics, rehydration capacity and energy consumption. Heat Mass Trans 53:2711–2718

Crank J (1975) The mathematics of diffusion. Oxford University Press, London

Darvishi H (2017) Quality, performance analysis, mass transfer parameters and modeling of drying kinetics of soybean. Braz J Chem Eng 34:143–148

Dilmaçünal T (2020) Controlled atmosphere and shelf life performance of a new late-maturing Japanese pear (Pyrus pyrifolia (Burm. F.) Nakai) cultivar ‘Atago. Not Bot Horti Agrobot Clujnapoca 48:177–188

Doymaz I (2013) Experimental study on drying of pear slices in a convective dryer. Int J Food Sci Technol 48:1909–1915

Doymaz I (2015) Infrared drying kinetics and quality characteristics of carrot slices. J Food Proces Preserv 39:2738–2745

FAO (2020) Food and agricultural organization statistica database. http://faostat3.fao.org/download/Q/QC/E. Accessed 22 Dec 2020

Guine RPF (2011) Influence of drying method on some physical and chemical properties of pears. Int J Fruit Sci 11:245–255

Guine RPF, Barroca MJ, Gonçalves FJ, Alves M, Oliveira S, Correia PMR (2015) Effect of drying on total phenolic compounds, antioxidant activity, and kinetics decay in pears. Int J Fruit Sci 15:173–186

Izli G, Taskin O, Izli N (2021) Convective, microwave and combined microwave-convective drying of pepino. Erwerbs-Obstbau. https://doi.org/10.1007/s10341-021-00555-9

Karacabey E, Baltacioglu C, Cevik M, Kalkan H (2016) Optimization of microwave-assisted drying of Jerusalem artichokes (Helianthus tuberosus L.) by response surface methodology and genetic algorithm. Italian J Food Sci 28:121–130

Kutlu N (2021) Optimization of ohmic heating-assisted osmotic dehydration as a pretreatment for microwave drying of quince. Food Sci Technol Int. https://doi.org/10.1177/1082013221991613

Li W, Yuan L, Xiao X, Yang X (2016) Dehydration of kiwifruit (Actinidia deliciosa) slices using heat pipe combined with impingement technology. Int J Food Eng 12:265–276

Liu Y, Sun C, Lei Y, Yu H, Xi H, Duan X (2019) Contact ultrasound strengthened far-infrared radiation drying on pear slices: effects on drying characteristics, microstructure, and quality attributes. Dry Technol 37:745–758

Lutovska M, Mitrevski V, Pvkov I, Mijakovski V, Radojcin M (2016) Mathematical modeling of thin layer drying of pear. Chem Ind Chem Eng Quart 22:191–199

Martynenko A, Kudra T (2016) Electrohydrodynamic (EHD) drying of grape pomace. Jpn J Food Eng 17:123–129

Oztekin YB, Sacilik K (2020) Drying characteristics of ‘Ankara’ pear slices. Italian J Food Sci 32:251–264

Taskin O, Polat A, Izli N, Asik BB (2019) Intermittent microwave-vacuum drying effects on pears. Polish J Food Nutr Sci 69:101–108

Vega-Galvez A, Uribe E, Poblete J, García V, Pastén A, Aguilera LE, Stucken K (2021) Comparative study of dehydrated papaya (Vasconcellea pubescens) by different drying methods: Quality attributes and effects on cells viability. J Food Meas Charact. https://doi.org/10.1007/s11694-021-00845-6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

İ. Doymaz declares that he has no conflict of interests.

Rights and permissions

Springer Nature oder sein Lizenzgeber (z.B. eine Gesellschaft oder ein*e andere*r Vertragspartner*in) hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Doymaz, İ. Influence of Infrared Drying on Some Quality Properties of Nashi Pear (Pyrus pyrifolia) Slices. Erwerbs-Obstbau 65, 47–54 (2023). https://doi.org/10.1007/s10341-022-00786-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00786-4