Abstract

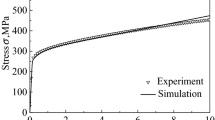

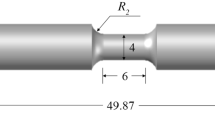

Under the framework of the small deformation crystal plasticity theory, a crystal plastic cyclic constitutive model for body-centered cubic (BCC) cyclic softening polycrystalline metals is established. The constitutive model introduces the isotropic softening rule that includes two different mechanisms: namely softening under monotonic deformation and softening under cyclic deformation on each slip system. Meanwhile, a modified Armstrong-Frederick nonlinear kinematic hardening rule is adopted. The appropriate explicit scale transition rule is selected to extend the single crystal constitutive model to the polycrystalline constitutive model. Then the model is used to predict the uniaxial and multiaxial ratcheting deformation of BCC axle steel EA4T to verify the rationality of the proposed model. The simulation results indicate that the newly established crystal plasticity model can not only describe the cyclic softening characteristics of BCC axle steel EA4T well, but also reasonably describe the evolution laws of uniaxial ratcheting and nonproportional multiaxial ratcheting deformation. Moreover, the established crystal plastic cyclic constitutive model can reasonably predict the ratcheting behavior of BCC single crystal as well.

Similar content being viewed by others

Availability of data and material

Data will be made available upon request.

References

Chaboche JL. A review of some plasticity and viscoplasticity constitutive theories. Int J Plast. 2008;24(10):1642–93.

Kang GZ. Ratchetting: Recent progresses in phenomenon observation, constitutive modeling and application. Int J Fatigue. 2008;30(8):1448–72.

Chaboche JL, Kanoute P, Azzouz F. Cyclic inelastic constitutive equations and their impact on the fatigue life predictions. Int J Plast. 2012;35:44–66.

Ohno N. Material models of cyclic plasticity with extended isotropic hardening: a review. Mech Eng Rev. 2015;2(1):14–00425.

Xu B, Jiang Y. A cyclic plasticity model for single crystals. Int J Plast. 2004;20(12):2161–78.

Cailletaud G, Sai K. A polycrystalline model for the description of ratchetting: effect of intergranular and intragranular hardening. Mater Sci Eng A. 2008;480(1–2):24–39.

Abdeljaoued D, Naceur I, Sai K, Cailletaud G. A new polycrystalline plasticity model to improve ratchetting strain prediction. Mech Res Commun. 2009;36(3):309–15.

Kang G, Bruhns OT. A new cyclic crystal visco-plasticity model based on combined nonlinear kinematic hardening rule for single crystals. Mater Res Innov. 2011;15(S1):S11–4.

Kang G, Bruhns OT, Sai K. Cyclic polycrystalline visco-plastic model for ratchetting of 316L stainless steel. Comput Mater Sci. 2011;50(4):1399–405.

Luo J, Kang GZ, Bruhns OT, et al. Cyclic polycrystalline viscoplastic model for ratchetting of a body centered cubic metal. Key Eng Mater. 2013;535–536:173–6.

Dong Y, Kang G, Yu C. A dislocation-based cyclic polycrystalline visco-plastic constitutive model for ratchetting of metals with face-centered cubic crystal structure. Comput Mater Sci. 2014;91(2):75–82.

Dong Y, Xie D, Zhang Y, et al. On the study of cyclic crystal plasticity ratchetting constitutive model for polycrystalline pure copper. Int J Appl Mech. 2019;11(4):1950041.

Yu C, Kang G, Kan Q, et al. A cyclic crystal viscoplastic model considering both dislocation slip and twinning. In: Advanced materials modelling for structures. Berlin: Springer; 2013.

Ren XH, Yang SP, Wen GL, Zhao WJ. A crystal-plasticity cyclic constitutive model for the ratchetting of polycrystalline material considering dislocation substructures. Acta Mech Solida Sin. 2020;33(2):268–80.

Zhao WJ. Cyclic constitutive model of high-speed railway train axle steel EA4T and finite element implementation. Hunan University; 2021. p.14–26.

Cailletaud G, Sai K. A polycrystalline model for the description of ratchetting: effect of intergranular and intragranular hardening. Mater Sci Eng, A. 2008;480(1):24–39.

Cruzado A, Llorca J, Segurado J. Modeling cyclic deformation of inconel 718 superalloy by means of crystal plasticity and computational homogenization. Int J Solids Struct. 2017;122:148–61.

Cruzado A, Lucarini S, LLorca J, et al. Crystal plasticity simulation of the effect of grain size on the fatigue behavior of polycrystalline Inconel 718. Int J Fatigue. 2018;113:236–45.

Asaro RJ, Needleman A. Overview no. 42 Texture development and strain hardening in rate dependent polycrystals. Acta Metall. 1985;33(6):923–53.

Tome C, Canova GR, Kocks UF, et al. The relation between macroscopic and microscopic strain hardening in FCC polycrystals. Acta Metall. 1984;32(10):1637–53.

Armstrong PJ, Frederick CO. A mathematical representation of the multiaxial Bauschinger effect. Central Electricity Generating Board [and] Berkeley Nuclear Laboratories. Research & Development Department; 1966.

Zhang KS, Ju JW, Li Z, et al. Micromechanics based fatigue life prediction of a polycrystalline metal applying crystal plasticity. Mech Mater. 2015;85:16–37.

Hill R. Continuum micro-mechanics of elastoplastic polycrystals. J Mech Phys Solids. 1965;13(2):89–101.

Yu C, Kang GZ, Sun Q, et al. Modeling the martensite reorientation and resulting zero/negative thermal expansion of shape memory alloys. J Mech Phys Solids. 2019;127:295–331.

Yu C, Chen T, Yin H, et al. Modeling the anisotropic elastocaloric effect of textured NiMnGa ferromagnetic shape memory alloys. Int J Solids Struct. 2020;191–192:509–28.

Dong Y, Zhu Y, Wu F, et al. A dual-scale elasto-viscoplastic constitutive model of metallic materials to describe thermo-mechanically coupled monotonic and cyclic deformations. Int J Mech Sci. 2022;224: 107332.

Cailletaud G, Pilvin P. Utilisation de modèlespolycristallins pour le calcul par élémentsfinis. Revue européenne des élémentsfinis. 1994;3(4):515–41.

Paquin A, Berbenni S, Favier V, et al. Micromechanical modeling of the elastic visco-plastic behaviour of polycrystalline steels. Int J Plast. 2001;17(9):1267–302.

Chaboche JL. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int J Plast. 1989;5(3):247–302.

Ohno N, Wang JD. Kinematic hardening rules with critical state of dynamic recovery, part I: Formulation basic features for ratcheting behaviour behaviour. Int J Plast. 1993;9(3):370–90.

Ohno N, Wang JD. Kinematic hardening rules with critical state of dynamic recovery, part II: application to experiments of ratchetting behavior. Int J Plast. 1993;9(3):391–403.

Abdel-Karim M, Ohno N. Kinematic hardening model suitable for ratchetting with steady-state. Int J Plast. 2000;16(3):225–40.

Zhao WJ, Yang SY, Wen GL, et al. Fractional-order visco-plastic constitutive model for uniaxial ratcheting behaviors. Appl Math Mech. 2019;40(1):49–62.

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (Nos.12032017, 11790282).

Funding

National Natural Science Foundation of China, 12032017, Shaopu Yang.

Author information

Authors and Affiliations

Contributions

XR provided all the data for this paper and was a major contributor to its writing. SY conceived the main idea of this paper and also put forward valuable suggestions for its revision. WZ and GW made great contributions to the revision of this paper. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent for publication

All authors have approved the final manuscript and its submission to the journal.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ren, X., Zhao, W., Yang, S. et al. A Cyclic Constitutive Model Based on Crystal Plasticity for Body-Centered Cubic Cyclic Softening Metals. Acta Mech. Solida Sin. 37, 33–42 (2024). https://doi.org/10.1007/s10338-023-00430-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00430-y