Abstract

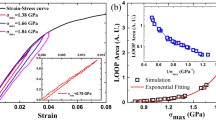

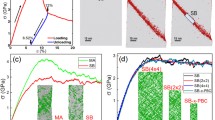

Shear banding in amorphous metals originates from the activation and percolation of flow units. To uncover the self-assembly dynamics of flow units in metallic glasses, a rectangular sample with two flow units embedded in the matrix undergoing simple shearing was analyzed using finite element simulations. The vortex evolution behavior, including activation, growth, and collapse during the self-assembly of flow units, was revealed. It was found that the formation of a mature vortex indicates the onset of yielding, and the collapse of the vortex represents the percolation of flow units or shear localization. The effects of initial free volume distribution and the distance between flow units on vortex behavior were also studied. Increasing the initial free volume concentration within flow units or the matrix leads to a gentler vortex evolution process and better homogeneous plasticity. The shape of vortex tends to be "flatter" with the increase in flow units’ spacing, and the optimal spacing was found to maximize the strength of the material.

Similar content being viewed by others

References

Argon AS. Plastic deformation in metallic glasses. Acta Metall. 1979;27:47–58.

Falk ML, Langer JS. Dynamics of viscoplastic deformation in amorphous solids. Phys Rev E. 1998;57(6):7192–205.

Wang WH. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog Mater Sci. 2012;57(3):487–656.

Falk ML Langer JS, Chen Y Trans, Wang YJ Proof, Deformation and failure of amorphous, solidlike materials. Advances in Mechanics. 2021;51(2): 406–26.

Liu YH, Wang G, Wang RJ, Zhao DQ, Pan MX, Wang WH. Super plastic bulk metallic glasses at room temperature. Science. 2007;315(5817):1385–8.

Liu YH, Wang D, Nakajima K, Zhang W, Hirata A, Nishi T, Inoue A, Chen MW. Characterization of nanoscale mechanical heterogeneity in a metallic glass by dynamic force microscopy. Phys Rev Lett. 2011;106(12): 125504.

Tian ZL, Wang YJ, Chen Y, Dai LH. Strain gradient drives shear banding in metallic glasses. Phys Rev B. 2017;96(9): 094103.

Chen Y, Jiang MQ, Dai LH. How does the initial free volume distribution affect shear band formation in metallic glass? Sci China Phys Mech Astron. 2011;54(8):1488–94.

Qiao JC, Wang Q, Pelletier JM, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog Mater Sci. 2019;104:250–329.

Zhang M, Chen Y, Li W. On the origin of softening in the plastic deformation of metallic glasses. Int J Plastic. 2019;116: 24–38.

Qian JC, Zhang LT, Tong Y, Lyu GJ, Hao Q, Tao K. Mechancial properties of amorphous alloys: In the framework of the microstructure heterogeneity. Adv Mech. 2022;51(1):117–52.

Schuh CA, Lund AC. Atomistic basis for the plastic yield criterion of metallic glass. Nat Mater. 2003;2(7):449–52.

Şopu D, Stukowski A, Stoica M, Scudino S. Atomic-level processes of shear band nucleation in metallic glasses. Phys Rev Lett. 2017;119(19): 195503.

Chen Y, Dai L. Failure behavior and criteria of metallic glasses. Acta Mech Sin. 2022;38: 121449.

Wang Z, Wen P, Huo LS, Bai HY, Wang WH. Signature of viscous flow units in apparent elastic regime of metallic glasses. Appl Phys Lett. 2012;101(12): 121906.

Yang ZY, Wang YJ, Dai LH. Hidden spatiotemporal sequence in transition to shear band in amorphous solids. Phys Rev Res. 2022;4(2):023220.

Jiang MQ, Wang WH, Dai LH. Prediction of shear-band thickness in metallic glasses. Scripta Mater. 2009;60(11):1004–7.

Zhang Y, Greer AL. Thickness of shear bands in metallic glasses. Appl Phys Lett. 2006;89(7): 071907.

Greer AL, Cheng YQ, Ma E. Shear bands in metallic glasses. Mater Sci Eng R. 2013;74(4):71–132.

Sunny G, Yuan F, Prakash V, Lewandowski J. Design of inserts for split-hopkinson pressure bar testing of low strain-to-failure materials. Exp Mech. 2008;49(4):479–90.

Bulatov VV, Argon AS. A stochastic model for continuum elasto-plastic behavior: I. Numerical approach and strain localization. Modell Simulat Mater Sci Eng. 1994;2: 167–84.

Lemaitre A, Caroli C. Rate-dependent avalanche size in athermally sheared amorphous solids. Phys Rev Lett. 2009;103(6):065501.

Scudino S, Şopu D. Strain distribution across an individual shear band in real and simulated metallic glasses. Nano Lett. 2018;18(2):1221–7.

Hieronymus-Schmidt V, Rösner H, Wilde G, Zaccone A. Shear banding in metallic glasses described by alignments of Eshelby quadrupoles. Phys Rev B. 2017;95(13): 134111.

Jiang MQ, Dai LH. On the origin of shear banding instability in metallic glasses. J Mech Phys Solids. 2009;57(8):1267–92.

Chen Y, Jiang MQ, Dai LH. Collective evolution dynamics of multiple shear bands in bulk metallic glasses. Int J Plast. 2013;50:18–36.

Dai LH. Shear banding in bulk metallic glasses. In: Dodd B, Bai YL, editors. Adiabatic shear localization: frontiers and advances. London: Elsevier; 2012. p. 311–61.

Lu H, Tang Y, Jiang F, Wan P, Zhou H. mechanical properties and deformation mechanisms of metallic glasses under hydrostatic pressure. Acta Mech Solida Sin. 2023. https://doi.org/10.1007/s10338-023-00390-3.

Padbidri JM, Hansen CM, Mesarovic SD, Muhunthan B. Length scale for transmission of rotations in dense granular materials. J Appl Mech. 2012;79(3): 031011.

Ding G, Jiang F, Dai L, Jiang M. Effective energy density of glass rejuvenation. Acta Mech Solida Sin. 2022;35(5):746–54.

Spaepen F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 1977;25:407–15.

Gao YF. An implicit finite element method for simulating inhomogeneous deformation and shear bands of amorphous alloys based on the free-volume model. Modell Simulat Mater Sci Eng. 2006;14(8):1329–45.

Acknowledgements

This work is supported by the NSFC (Nos. 11972346 and 11790292), and the NSFC Basic Science Center Program for ''Multi-scale Problems in Nonlinear Mechanics'' (No. 11988102).

Author information

Authors and Affiliations

Contributions

JL contributed to simulation and writing—original draft. RS contributed to simulation and writing—original draft. YC contributed to conceptualization, analyses, supervision, and writing—original draft, review and editing. LD contributed to writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Consent for Publication

All authors approved the final manuscript and the submission to this journal.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lian, J., Song, R., Chen, Y. et al. Vortex Evolution Behavior in Self-Assembly of Flow Units in Metallic Glasses. Acta Mech. Solida Sin. 36, 603–611 (2023). https://doi.org/10.1007/s10338-023-00409-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00409-9