Abstract

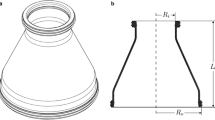

The rubber cylinder is a key component for maintaining the sealing pressure of the packer, particularly in deep underground wells. The stress relaxation of materials, as a typical feature of viscoelasticity, has become one of the main factors causing the failure of rubber cylinders in service. In the present study, a visco-hyperelastic model for the sealing rubber considering different strain levels is proposed based on the Prony series. Subsequently, the uniaxial compression stress relaxation experiments are conducted on the sealing rubber under different temperatures and strain levels, and the model parameters are thereby identified. As a case study, the proposed model is incorporated into the ABAQUS software via the UMAT subroutine, and the finite element simulation of the sealing packer is carried out. The results show that the sealing performance of the packer improves with a decrease in temperature or an increase in strain level. It is also noted that a large strain level can lead to the protrusion of the shoulder of the rubber cylinder.

Similar content being viewed by others

Data Availability

All data generated during this study are publicly available.

References

Yeoh OH. Some forms of the strain energy function for rubber. Rubber Chem Technol. 2012;66(5):754–71.

Khajehsaeid H, Arghavani J, Naghdabadi R. A hyperelastic constitutive model for rubber-like materials. Eur J Mech A Solid. 2013;38:144–51.

Horgan CO, Murphy JG. On the volumetric part of strain-energy functions used in the constitutive modeling of slightly compressible solid rubbers. Int J Solids Struct. 2009;46(16):3078–85.

Fereidoonnezhad B, Naghdabadi R, Arghavani J. A hyperelastic constitutive model for fiber-reinforced rubber-like materials. Int J Eng Sci. 2013;71:36–44.

Laine E, Grandidier JC, Benoit G, et al. Non-contact method used to determine the swelling/shrinking coefficients under CO2 sorption/desorption on an HNBR O-ring–Study of coupling with temperature and pressure. Polym Test. 2020;85(1):106411.

Dal H, Gueltekin O, Acikgoz K. An extended eight-chain model for hyperelastic and finite viscoelastic response of rubberlike materials: Theory, experiments and numerical aspects. J Mech Phys Solids. 2020;145:104159.

Gong Y, Liu F, Zou R, et al. A simple anisotropic visco-hyperelastic constitutive model for cord-rubber composites. Compos Commun. 2021;28:100957.

Zhong D, Xiang Y, Wang Z, et al. A visco-hyperelastic model for hydrogels with tunable water content. J Mech Phys Solids. 2023;173:105206.

Li C, Lua J. A hyper-viscoelastic constitutive model for polyurea. Mater Lett. 2009;63(11):877–80.

Peng Q, Zhu Z, Jiang C, et al. Effect of stress relaxation on accelerated physical aging of hydrogenated nitrile butadiene rubber using time-temperature-strain superposition principle. Adv Ind Eng Polym Res. 2019;2(2):61–8.

Khajehsaeid H, Arghavani J, Naghdabadi R, et al. A visco-hyperelastic constitutive model for rubber-like materials: a rate-dependent relaxation time scheme. Int J Eng Sci. 2014;79:44–58.

Fazekas B, Goda TJ. Constitutive modelling of rubbers: mullins effect, residual strain, time-temperature dependence. Int J Mech Sci. 2021;210:106735.

Wang B, Kari L. Constitutive model of isotropic magneto-sensitive rubber with amplitude, frequency, magnetic and temperature dependence under a continuum mechanics basis. Polym Basel. 2020;13:472–87.

Janbaz M, Googarchin HS. Experimental and numerical analysis on magneto-hyper-viscoelastic constitutive responses of magnetorheological elastomers: a characterization procedure. Mech Mater. 2021;154:1–18.

Xu X, Yan H, Xiao C, et al. An anisotropic hyper-visco-pseudo-elastic model and explicit stress solutions for fabric reinforced rubber composites. Int J Solids Struct. 2022;242:111519.

Tada T, Urayama K, Mabuchi T, et al. Nonlinear stress relaxation of carbon black-filled rubber vulcanizates under various types of deformation. J Polym Sci Pol Phys. 2010;48(12):1380–7.

Zhang X, Wu J, Xu Z, et al. Comparative study on the molecular chain orientation and strain-induced crystallization behaviors of HNBR with different acrylonitrile content under uniaxial stretching. Polymer. 2021;219:123520.

Dong L, Li K, Zhu X, et al. Study on high temperature sealing behavior of packer rubber tube based on thermal aging experiments. Eng Fail Anal. 2020;108:104321.

Amin AFMS, Alam MS, Okui Y. An improved hyperelasticity relation in modeling viscoelasticity response of natural and high damping rubbers in compression: experiments, parameter identification and numerical verification. Mech Mater. 2002;34(2):75–95.

Salimi A, Abbassi-Sourki F, Karrabi M, et al. Investigation on viscoelastic behavior of virgin EPDM/ reclaimed rubber blends using Generalized Maxwell Model (GMM). Polym Test. 2021;93:106989.

Rangarajan SE, Ramarathnam KK. Viscoelastic properties of natural rubber with fatigue damage. Int J Fatigue. 2021;150:106344.

Hoo Fatt MS, Ouyang X. Integral-based constitutive equation for rubber at high strain rates. Int J Solids Struct. 2007;44(20):6491–506.

Gamonpilas C, McCuiston R. A non-linear viscoelastic material constitutive model for polyurea. Polymer. 2012;53(17):3655–8.

Ghoreishy MHR. Determination of the parameters of the Prony series in hyper-viscoelastic material models using the finite element method. Mater Design. 2012;35:791–7.

Yang H, Yao XF, Yan H, et al. Anisotropic hyper-viscoelastic behaviors of fabric reinforced rubber composites. Compos Struct. 2018;187:116–21.

Jin L, Li S, Cheng Y, et al. A time-dependent Yeoh model to predict the corrosion effect of supercritical CO2 on the HNBR sealing rubber. J Mech Sci Technol. 2022;36(5):2461–70.

Zhang J, Xia P. An improved PSO algorithm for parameter identification of nonlinear dynamic hysteretic models. J Sound Vib. 2017;389:153–67.

Veivers H, Bermingham M, Dunn M, et al. Layup optimisation of laminated composite tubular structures under thermomechanical loading conditions using PSO. Compos Struct. 2021;276:114483.

Leng DX, Huang C, Xu K, et al. Experimental mechanics and numerical prediction on stress relaxation and unrecoverable damage characteristics of rubber materials. Polym Test. 2021;98:107183.

Huang Y, Li Y, Zhao H, et al. Research on constitutive models of hydrogenated nitrile butadiene rubber for packer at different temperatures. J Mech Sci Technol. 2020;34(1):155–64.

Dong L, Li K, Li B, et al. Study in deep shale gas well to prevent shoulder protruding packer with high pressure sealing. Eng Fail Anal. 2020;118:104871.

Zheng X, Li B. Study on sealing performance of packer rubber based on stress relaxation experiment. Eng Fail Anal. 2021;129:105692.

Wang H, Chen S, Liu Y, et al. Numerical simulation and experimental validation for design improvement of packer rubber. Int J Simul Process Model. 2017;12(5):419–28.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (11972375, 12211530028), the Natural Science Foundation of Shandong Province (ZR202011050038, ZR2022MA086), the Science and Technology Project in Qingdao Developing Zone (2020-81), and Special Funds for the Basic Scientific Research Expenses of Central Government Universities (2472022X03006A).

Author information

Authors and Affiliations

Contributions

LJ contributed to methodology and writing original draft; DZ contributed to review and funding; JL contributed to formal analysis, review, and funding.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial and personal relationships with other people or organizations that can inappropriately influence our work, and there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, L., Zhao, D. & Liu, J. A Visco-hyperelastic Constitutive Model for Rubber Considering the Strain Level and One Case Study in the Sealing Packer. Acta Mech. Solida Sin. 36, 710–723 (2023). https://doi.org/10.1007/s10338-023-00397-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00397-w