Abstract

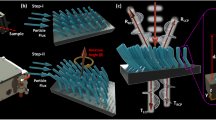

Magnetic kirigami with tunable configurations under magnetic actuation is of significant interest in various emerging fields. However, there remains a grand challenge to develop magnetic kirigami with a facile fabrication strategy, programmable magnetization, and functionality. In this work, we present a novel magnetic kirigami that is readily fabricated by the laser cutting technique. The magnetic kirigami consists of an array of magnetic microplates, each with a programmed magnetization. By applying an actuation magnetic field, each microplate can rotate and even flip, allowing for predesigned kirigami configurations. By further coating the surface of the microplate array, the magnetic kirigami can be programmed with functionality. We demonstrate a potential application of information encryption by engineering magnetic kirigami into a magneto-responsive QR code. Providing a simple fabrication strategy, our work paves the way for other applications of magnetic kirigami.

Similar content being viewed by others

Availability of data and material

Data and materials are provided in the main text and supplementary information. Further information is available from the corresponding authors upon reasonable request.

References

Cheng YC, Lu HC, Lee X, Zeng H, Priimagi A. Kirigami-based light-induced shape-morphing and locomotion. Adv Mater. 2020;32(7): e1906233.

Shyu TC, Damasceno PF, Dodd PM, Lamoureux A, Xu L, Shlian M, Shtein M, Glotzer SC, Kotov NA. A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat Mater. 2015;14(8):785–9.

Rafsanjani A, Zhang Y, Liu B, Rubinstein SM, Bertoldi K. Kirigami skins make a simple soft actuator crawl. Sci Robot. 2018;3(15):eaar7555.

Song Z, Wang X, Lv C, An Y, Liang M, Ma T, He D, Zheng YJ, Huang SQ, Yu H, Jiang H. Kirigami-based stretchable lithium-ion batteries. Sci Rep. 2015;5:10988.

Li H, Wang W, Yang Y, Wang Y, Li P, Huang J, Li J, Lu Y, Li Z, Wang Z, Fan B, Fang J, Song W. Kirigami-based highly stretchable thin film solar cells that are mechanically stable for more than 1000 cycles. ACS Nano. 2020;14(2):1560–8.

Xu L, Wang X, Kim Y, Shyu TC, Lyu J, Kotov NA. Kirigami nanocomposites as wide-angle diffraction gratings. ACS Nano. 2016;10(6):6156–62.

Blees MK, Barnard AW, Rose PA, Roberts SP, McGill KL, Huang PY, Ruyack AR, Kevek JW, Kobrin B, Muller DA, McEuen PL. Graphene kirigami. Nature. 2015;524(7564):204–7.

Jiralerspong T, Bae G, Lee JH, Kim SK. Wireless control of two- and three-dimensional actuations of kirigami patterns composed of magnetic-particles-polymer composites. ACS Nano. 2020;14:17589–96.

Sun Q, Wang D, Li Y, Zhang J, Ye S, Cui J, Chen L, Wang Z, Butt HJ, Vollmer D, Deng X. Surface charge printing for programmed droplet transport. Nat Mater. 2019;18(9):936–41.

Oh I, Keplinger C, Cui JX, Chen JH, Whitesides GM, Aizenberg J, Hu YH. Dynamically actuated liquid-infused poroelastic film with precise control over droplet dynamics. Adv Func Mater. 2018;28(39):1802632.

Chen C, Huang Z, Jiao Y, Shi LA, Zhang Y, Li J, Li C, Lv X, Wu S, Hu Y, Zhu W, Wu D, Chu J, Jiang L. In situ reversible control between sliding and pinning for diverse liquids under ultra-low voltage. ACS Nano. 2019;13(5):5742–52.

Xu B, Zhu C, Qin L, Wei J, Yu Y. Light-directed liquid manipulation in flexible bilayer microtubes. Small. 2019;15(24): e1901847.

Sun L, Bian F, Wang Y, Wang Y, Zhang X, Zhao Y. Bioinspired programmable wettability arrays for droplets manipulation. Proc Natl Acad Sci U S A. 2020;117(9):4527–32.

Wang J, Gao W, Zhang H, Zou M, Chen Y, Zhao Y. Programmable wettability on photocontrolled graphene film. Sci Adv. 2018;4(9):eaat7392.

Wang W, Timonen JVI, Carlson A, Drotlef DM, Zhang CT, Kolle S, Grinthal A, Wong TS, Hatton B, Kang SH, Kennedy S, Chi J, Blough RT, Sitti M, Mahadevan L, Aizenberg J. Multifunctional ferrofluid-infused surfaces with reconfigurable multiscale topography. Nature. 2018;559(7712):77–82.

Guo J, Wang D, Sun Q, Li L, Zhao H, Wang D, Cui J, Chen L, Deng X. Omni-liquid droplet manipulation platform. Adv Mater Interfaces. 2019;6(16): e1900653.

Miao L, Song Y, Ren Z, Xu C, Wan J, Wang H, Guo H, Xiang Z, Han M, Zhang H. 3D temporary-magnetized soft robotic structures for enhanced energy harvesting. Adv Mater. 2021;33(40): e2102691.

Wang J, Yi S, Yang Z, Chen Y, Jiang L, Wong CP. Laser direct structuring of bioinspired spine with backward microbarbs and hierarchical microchannels for ultrafast water transport and efficient fog harvesting. ACS Appl Mater Interfaces. 2020;12(18):21080–7.

Wang M, Liu Q, Zhang H, Wang C, Wang L, Xiang B, Fan Y, Guo CF, Ruan S. Laser direct writing of tree-shaped hierarchical cones on a superhydrophobic film for high-efficiency water collection. ACS Appl Mater Interfaces. 2017;9(34):29248–54.

Yi S, Wang L, Chen Z, Wang J, Song X, Liu P, Zhang Y, Luo Q, Peng L, Wu Z, Guo CF, Jiang L. High-throughput fabrication of soft magneto-origami machines. Nat Commun. 2022;13(1):4177.

Zhu H, Wang Y, Ge Y, Zhao Y, Jiang C. Kirigami-inspired programmable soft magnetoresponsive actuators with versatile morphing modes. Adv Sci. 2022;9(32): e2203711.

Wang J, Zhu Z, Liu P, Yi S, Peng L, Yang Z, Tian X, Jiang L. Magneto-responsive shutter for on-demand droplet manipulation. Adv Sci. 2021;8(23): e2103182.

Jiang S, Hu Y, Wu H, Zhang Y, Zhang Y, Wang Y, Zhang Y, Zhu W, Li J, Wu D, Chu J. Multifunctional janus microplates arrays actuated by magnetic fields for water/light switches and bio-inspired assimilatory coloration. Adv Mater. 2019;31(15): e1807507.

Chen Z, Lin Y, Zheng G, Yang Y, Zhang Y, Zheng S, Li J, Li J, Ren L, Jiang L. Programmable transformation and controllable locomotion of magnetoactive soft materials with 3D-patterned magnetization. ACS Appl Mater Interfaces. 2020;12(52):58179–90.

Wang L, Kim Y, Guo CF, Zhao X. Hard-magnetic elastica. J Mech Phys Solids. 2020;142: e104045.

Zhao R, Kim Y, Chester SA, Sharma P, Zhao X. Mechanics of hard-magnetic soft materials. J Mech Phys Solids. 2019;124:244–63.

Funding

National Natural Science Foundation of China (Project Nos. 51975597, 21872176, 22072185, and 12272369), Natural Science Foundation of Guangdong Province (Project Nos. 2019A1515011011 and 2022A1515011065), Special Support Plan for High Level Talents in Guangdong Province (Project No. 2017TQ04X674), Key Research and Development Plan of Guangdong Province (Project No. 2018B0909060), Pearl River Talents Program of Guangdong Province (Project No. 2017GC010671), and Organized scientific research project of Guangdong Normal University of Technology (Project No.22GPNUZDJS21).

Author information

Authors and Affiliations

Contributions

JW contributed to conceptualization, investigation, methodology, experiments, visualization, writing—original draft. YZ and LX contributed to writing, revising—revised draft. LJ contributed to conceptualization, visualization, writing—original draft. LW contributed to conceptualization, methodology, writing—review. LJ and LW supervised the work.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethics Approval

The paper presented obeys the ethical responsibilities required by Acta Mechanica Solida Sinica.

Consent for Publication

The authors of this paper give consent for its publication in Acta Mechanica Solida Sinica.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Zhou, Y., Xu, L. et al. Magnetic Kirigami by Laser Cutting. Acta Mech. Solida Sin. 36, 594–601 (2023). https://doi.org/10.1007/s10338-023-00394-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00394-z