Abstract

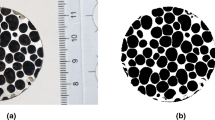

The permanent residual strain in aluminum (Al) alloy foams induced by compressive fatigue gradually increases with the increasing number of loading cycles. Consequently, the progressive shortening of Al-alloy foam degrades the dynamic material performance by the failure and ratcheting of multi-cells in the foam. In this paper, the dynamic properties of Al-alloy foams damaged by compressive fatigue were studied. The beam specimens with various residual strains were made by cyclic compression-compression stress. The dynamic bending modulus and loss factor were evaluated by using a beam transfer function method. As a result, the dynamic bending stiffness of Al-alloy foam turned out to be decreased due to damage while the loss factor was improved because of the increasing energy dissipation of such factors as cracked cell walls formed during the shortening process of the foam. The loss factor shows a manifest dependence on the fatigue residual strain.

Similar content being viewed by others

References

Ashby, M.F., Evans, A.G., Fleck, N.A., Gibson, L.J., Hutchinson, J.W. and Wadley, H.G.N., Metals Foams: A Design Guide, Boston USA: Butterworth Heinemann, 2000.

Gui, M.C., Wang, D.B., Wu, J.J., Yuan, G.J. and Li, C.G., Deformation and damping behaviors of foamed Al-Si-SiCp composite. Material Science and Engineering A, 2000, 286: 282–288.

Golovin, I.S. and Sinning, H.R., Damping in some cellular metallic materials. Journal of Alloys and Compound, 2003, 355, 2–9.

Lins, W., Kaindl, G., Peterlik, H. and Kromp, K., A novel resonant beam technique to determine the elastic moduli in dependence on orientation and temperature up to 2000° C. Review of Scientific Instruments, 1999, 70: 3052–3058.

Thompson, R.B., Alers, G.A., Thompson, D.O., Tennison, M.A., Dispersion of flexural elastic waves in honeycomb sandwich panels. Journal of the Acoustical Society of America, 1975, 57: 1119–1127.

Park, J., Transfer function methods to measure dynamic mechanical properties of complex structures. Journal of Sound and Vibration, 2005, 288: 57–79.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by Chungnam Automotive Technology Education Center (NURI).

Rights and permissions

About this article

Cite this article

Kim, SG., Kim, I., Kim, A. et al. Dynamic Properties of Al-Alloy Foam Beam Damaged by Compressive Fatigue. Acta Mech. Solida Sin. 21, 241–246 (2008). https://doi.org/10.1007/s10338-008-0827-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-008-0827-0