Abstract

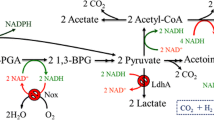

A time- and cost-efficient two-step gene elimination procedure was used for acetogen Clostridium sp. MT1834 capable of fermenting CO2/H2 blend to 245 mM acetate (p < 0.005). The first step rendered the targeted gene replacement without affecting the total genome size. We replaced the acetate pta-ack cluster with synthetic bi-functional acetaldehyde-alcohol dehydrogenase (al-adh). Replacement of pta-ack with al-adh rendered initiation of 243 mM ethanol accumulation at the expense of acetate production during CO2/H2 blend continuous fermentation (p < 0.005). At the second step, al-adh was eliminated to reduce the genome size. Resulting recombinants accumulated 25 mM mevalonate in fermentation broth (p < 0.005). Cell duplication time for recombinants with reduced genome size decreased by 9.5 % compared to Clostridium sp. MT1834 strain under the same fermentation conditions suggesting better cell energy pool management in the absence of the ack-pta gene cluster in the engineered biocatalyst. If the first gene elimination step was used alone for spo0A gene replacement with two copies of synthetic formate dehydrogenase in recombinants with a shortened genome, mevalonate production was replaced with 76.5 mM formate production in a single step continuous CO2/H2 blend fermentation (p < 0.005) with cell duplication time almost nearing that of the wild strain.

Similar content being viewed by others

References

Abubackar HN, Veiga MC, Kennes C (2012) Biological conversion of carbon monoxide to ethanol: effect of pH, gas pressure, reducing agent and yeast extract. Bioresource Technol 114:518–522

Berzin V, Tyurin M (2012) Acetogen biocatalyst Clostridium sp. MTEtOH871 engineered with our proprietary electrotransformation technology and equipment: continuous synthesis gas fermentation for selective ethanol production. J Biotech Res 4:54–64

Berzin V, Kiriukhin M, Tyurin M (2012) Elimination of acetate production to improve ethanol yield during continuous synthesis gas fermentation by engineered biocatalyst Clostridium sp. MTEtOH550. Appl Biochem Biotechnol 167(2):338–347. doi:10.1007/s12010-012-9697-5

Berzin V, Kiriukhin M, Tyurin M (2012) Cre-lox66/lox71-based elimination of phosphotransacetylase or acetaldehyde dehydrogenase shifted carbon flux in acetogen rendering selective overproduction of ethanol or acetate. Appl Biochem Biotechnol 195(3):181–188. doi:10.1007/s12010-012-9864-8

Berzin V, Kiriukhin M, Tyurin M (2012) Selective production of acetone during continuous synthesis gas fermentation by engineered biocatalyst Clostridium sp. MAceT113. Lett Appl Microbiol 55(2):149–54. doi:10.1111/j.1472-765X.2012.03272.x

Berzin V, Kiriukhin M, Tyurin M (2013) “Curing” of plasmid DNA in acetogen using microwave or applying an electric pulse improves cell growth and metabolite production as compared to the plasmid-harboring strain. Arch Microbiol 195(3):181–188. doi:10.1007/s00203-012-0862-6

Berzin V, Kiriukhin M, Tyurin M (2013) Selective n-butanol production by Clostridium sp. MTButOH1365 during continuous synthesis gas fermentation due to expression of synthetic thiolase, 3-hydroxy butyryl-CoA dehydrogenase, crotonase, butyryl-CoA dehydrogenase, butyraldehyde dehydrogenase and NAD-dependent butanol dehydrogenase. Appl Biochem Biotechnol 169(3):950–959. doi:10.1007/s12010-012-0060-7

Cheung H, Tanke RS, Torrence GP (2005) “Acetic Acid”. In: Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_045

Csörgo B, Fehér T, Tímár E, Blattner FR, Pósfai G (2012) Low-mutation-rate, reduced-genome Escherichia coli: an improved host for faithful maintenance of engineered genetic constructs. Microb Cell Fact 11:11. doi:10.1186/1475-2859-11-11

Datsenko KA, Wanner BL (2000) One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc Natl Acad Sci USA 97(12):6640–6645

Demain AL (2009) Biosolutions to the energy problem. J Ind Microbiol Biotechnol 36(3):319–332

Fischer CR, Klein-Marcuschamer D, Stephanopoulos G (2008) Selection and optimization of microbial hosts for biofuels production. Metab Eng 10(6):295–304

Gaddy JL, Arora DD, Ko C-W, Phillips JR, Basu R, Wikstrom CV, Clausen EC (2001) Methods for increasing the production of ethanol from microbial fermentation. US Patent 7285402

Global Industry Analysts, Inc. http://www.prweb.com/releases/formic_acid/leather_textiles/prweb1569064.htm

Goldenstein C (2011) Algae Energy Costs. Coursework for PH240, Stanford University. http://large.stanford.edu/courses/2011/ph240/goldenstein1/.i

Köpke M, Michalcea C, Liew F-M, Tizard JH, Ali MS, Conolly JJ, Al-Sinawi B, Simpson SD (2011) 2, 3-Butanediol production by acetogenic bacteria, an alternative route to chemical synthesis, using industrial waste gas. Appl Environ Microbiol 77(15):5467–5475

Lee JH, Sung BH, Kim MS, Blattne r FR, Yoon BH, Kim JH, Kim SC (2009) Metabolic engineering of a reduced-genome strain of Escherichia coli for l-threonine production. Microb Cell Factories 8:2. doi: 10.1186/1475-2859-8-2

Munasinghe PC, Khanal SK (2010) Biomass-derived syngas fermentation into biofuels: opportunities and challenges. Bioresource Technol 101:5013–5022

Reutemann W, Kieczka H (2002) “Formic Acid”. In: Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim. doi: 10.1002/14356007.a12_013

Robinson JM (2004) Lactones as new oxygenate fuel additives, fuels based thereon and methods for using same. US 20060096158Al

Ross SM (2000) Introduction to probability and statistics for engineers and scientists, 2nd edn. Academic Press, San Diego

Siddiqi MA, Rodwell VW (1967) Bacterial metabolism of mevalonic acid. J Bacteriol 93(1):207–214

Tanner RS, Miller LM, Yang D (1993) Clostridium ljungdahlii sp. nov., an acetogenic species in clostridial rRNA homology group I. Int J Systemic Bacteriol 43(2):232–236

Tyurin MV (1992) The method and apparatus for electric cell treatment using partial power capacitor discharge via the sample and the power tetrode. Russian Patent 2005776

Tyurin M, Lynd LR, Wiegel J (2006) Genetic delivery systems for strictly anaerobic thermophiles. In: Rainey, FA, Oren A (eds) Methods in microbiology, 1st edn, vol 35, pp 307–328. Elsevier, Academic Press, Amsterdam, Boston

Tyurin M, Kiriukhin M, Berzin V (2012) Electrofusion of cells of acetogen Clostridium sp. MT351 with erm(B) or cat in the chromosome. J Biotech Res 4:1–12

Tyurin M, Kiriukhin M (2013) Expression of amplified synthetic ethanol pathway integrated using Tn7-tool and powered at the expense of eliminated pta, ack, spo0A and spo0J during continuous syngas or CO2/H2 blend fermentation. J Appl Microbiol. doi:10.1111/jam.12123

Van Laar TA, Lin Y-H, Miller CL, Karna SLR, Chambers JP, Seshu J (2012) Effect of levels of acetate on the mevalonate pathway of Borrelia burgdorferi. PLoS ONE 7(5):e38171. doi:10.1371/journal.pone.0038171

Van Leeuwen BNM, van der Wulp AM, Duijnstee I, van Maris AJA, Straathof AJJ (2012) Fermentative production of isobutene. Appl Microbiol Biotechnol 93(4):1377–1387. doi:10.1007/s00253-011-3853-7

Volker M (2003) Energy conservation in acetogenic bacteria. Appl Envir Microbiol 69(11):6345–53. doi: 10.1128/AEM.69.11.6345-6353.2003

Yang J, Xian M, Su S, Zhao G, Nie Q, Jiang X, Zheng Y, Liu W (2012) Enhancing production of bio-isoprene using hybrid MVA pathway and isoprene synthase in E. coli. PLoS ONE 7(4):e33509. doi:10.1371/journal.pone.0033509

Young KD (2006) The selective value of bacterial shape. Microbiol Mol Biol Rev 70(3):660–703. doi:10.1128/MMBR.00001-06

Acknowledgments

The research was supported by the funds of angel friends to MT family. The authors declare that they do not have any conflict of interest, and they have agreed to submit this manuscript to the “Journal of Industrial Microbiology and Biotechnology”. Syngas Biofuels Energy, Inc. and its successors are the sole distributors of the electroporation and electrofusion equipment: www.syngasbiofuelsenergy.com.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tyurin, M. Gene replacement and elimination using λRed- and FLP-based tool to re-direct carbon flux in acetogen biocatalyst during continuous CO2/H2 blend fermentation. J Ind Microbiol Biotechnol 40, 749–758 (2013). https://doi.org/10.1007/s10295-013-1279-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-013-1279-1