Abstract

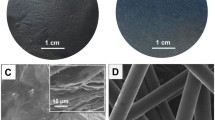

We describe a latex wet coalescence method for gas-phase immobilization of microorganisms on paper which does not require drying for adhesion. This method reduces drying stresses to the microbes. It is applicable for microorganisms that do not tolerate desiccation stress during latex drying even in the presence of carbohydrates. Small surface area, 10–65 μm thick coatings were generated on chromatography paper strips and placed in the head-space of vertical sealed tubes containing liquid to hydrate the paper. These gas-phase microbial coatings hydrated by liquid in the paper pore space demonstrated absorption or evolution of H2, CO, CO2 or O2. The microbial products produced, ethanol and acetate, diffuse into the hydrated paper pores and accumulate in the liquid at the bottom of the tube. The paper provides hydration to the back side of the coating and also separates the biocatalyst from the products. Coating reactivity was demonstrated for Chlamydomonas reinhardtii CC124, which consumed CO2 and produced 10.2 ± 0.2 mmol O2 m−2 h−1, Rhodopseudomonas palustris CGA009, which consumed acetate and produced 0.47 ± 0.04 mmol H2 m−2 h−1, Clostridium ljungdahlii OTA1, which consumed 6 mmol CO m−2 h−1, and Synechococcus sp. PCC7002, which consumed CO2 and produced 5.00 ± 0.25 mmol O2 m−2 h−1. Coating thickness and microstructure were related to microbe size as determined by digital micrometry, profilometry, and confocal microscopy. The immobilization of different microorganisms in thin adhesive films in the gas phase demonstrates the utility of this method for evaluating genetically optimized microorganisms for gas absorption and gas evolution.

Similar content being viewed by others

References

Arbubackar HN, Veiga MC, Kennes C (2011) Biological conversion of carbon monoxide: rich syngas or waste gases to bioethanol. Biofuel Bioprod Biorefin 5:93–114

Berger RG (2009) Biotechnology of flavours-the next generation. Biotechnol Lett 31:1651–1659

Bredwell MD, Srivastava P, Worden RM (1999) Reactor design issues for synthesis-gas fermentations. Biotechnol Prog 15:834–844

Carballeira JD, Quezada MA, Hoyos P, Simeo Y, Hernaiz MJ, Alcantara AR, Sinisterra JV (2009) Microbial cells as catalysts for stereoselective red-ox reactions. Biotechnol Adv 27:686–714

Clark WM, Jackson YZ, Morin MT, Ferraro GP (2011) Combining experiments and simulation of gas absorption for teaching mass transfer fundamentals: removing CO2 from air using water and NaOH. Chem Eng Edu 45:133–143

Cussler E (2009) Diffusion mass transfer in fluid systems, 3rd edn. Cambridge University Press, Cambridge

Datta R, Tsai S-P, Basu R, Yoon S-H (2009) Membrane supported bioreactor for conversion of syngas components to liquid products. US Patent Application 2009/0017514 A1

Demain AL (2009) Biosolutions to the energy problem. J Ind Microbiol Biotechnol 36:319–332

Di Risio S, Yan N (2008) Bioactive paper through inkjet printing. J Adhes Sci Technol 24:661–684

End N, Schoning KU (2004) Immobilized biocatalysts in industrial research and production. In: Kirschning A (ed) Immobilized catalysts, vol 242. Springer, New York, pp 273–317

Derby B (2008) Bioprinting: inkjet printing proteins and hybrid cell-containing materials and structures. J Materials Chem 18:5717–5721

Fidaleo M, Flickinger MC (2011) Engineering and modeling of thin, adhesive microbial biocatalytic coatings for high intensity oxidations in multi-phase microchannel bioreactors. J Chem Eng Sci 66:3251–3257

Flickinger MC, Fidaleo M, Gosse JL, Polzin K, Charaniya S, Solheid C, Lynberg OK, Laudon M, Ge H, Schottel JL, Bond DR, Aksan A, Scriven LE (2009) Engineering nanoporous bioactive smart coatings containing microorganisms: fundamentals and emerging applications. In: Provider T, Baghdachi J (eds) Smart coatings II, ACS symposium series 1002: Washington, pp 52–94

Flickinger MC, Schottel JL, Bond DR, Aksan A, Scriven LE (2007) Painting and printing living bacteria: engineering nanoporous biocatalytic coatings to preserve microbial viability and intensify reactivity. Biotechnol Prog 23:2–17

Flickinger MC, Lyngberg OK, Freeman EA, Anderson CR, Laudon MC (2009) Formulation of reactive nanostructured adhesive microbial ink-jet inks for miniature biosensors and biocatalysis. In: Fernando RH, Sung L-P (eds) Nanotechnology applications in coatings. ACS Symposium Series 1008: Washington, pp 156–187

Giorno L, Drioli E (2010) Biocatalytic membrane reactors. In: Flickinger MC (ed) Encyclopedia of industrial biotechnology, bioprocess, bioseparation and cell technology. Wiley, Hoboken, pp 512–533

Gosse JL, Engel BJ, Hui JCH, Harwood CS, Flickinger MC (2010) Progress toward a biomimetic leaf: 4,000 h of hydrogen production by coating-stabilized nongrowing photosynthetic Rhodopseudomonas palustris. Biotechnol Prog 26:907–918

Gosse JL, Engel BJ, Rey FE, Harwood CS, Scriven LE, Flickinger MC (2007) Hydrogen production by photoreactive nanoporous latex coatings of nongrowing Rhodopseudomonas palustris CGA009. Biotechnol Prog 23:124–130

Harris EH (1989) The Chlamydomonas sourcebook—a comprehensive guide to biology and laboratory use. Academic, San Diego, p 780

Hickey RF, Basu R, Datta R, Tsai S-P (2010) Method for conversion of syngas using micro-organism on hydrophilic membrane. US Patent Application 2010/00478861 A1

Kennes C, Rene ER, Veiga MC (2009) Bioprocesses for air pollution control. J Chem Technol Biotechnol 84:1419–1436

Köpke M, Held C, Hujer S, Liesegang H, Wiezer A, Wollherr A, Ehrenreich A, Liebl W, Gottschalk G, Dürre P (2010) Clostridium ljungdahlii represents a microbial production platform based on syngas. PNAS USA 107:13087–13092

Leino H, Kosourov SN, Saari L, Sivonen K, Tsygankov AA, Aro E-M, Allahverdiyeva Y (2012) Extended H2 production by N2-fixing cyanobacteia immobilized in thin alginate films. Int J Hyd Energy 37:151–161

Levin DB (2004) Re: Biohydrogen production: prospects and limitations to practical application—Erratum. Inter J Hyd Energy 29:1425–1426

Levin DB, Pitt L, Love M (2004) Biohydrogen production: prospects and limitations to practical application. Int J Hyd Energy 29:173–185

Lu J-G, Fan F, Liu C, Ji Y, Zhang H (2011) Membrane contactor as reactor for CO2 capture. Int J Chem Reactor Eng 9:A41

Lyngberg OK, Solheid C, Charaniya S, Ma Y, Thiagarajan V, Scriven LE, Flickinger MC (2005) Permeability and reactivity of Thermotoga maritimain latex bimodal blend coatings at 80 °C: a model high temperature biocatalytic coating. Extremophiles 9:197–207

Prince RC, Kheshgi HS (2005) The photobiological production of hydrogen: potential efficiency and effectiveness as a renewable fuel. Crit Rev Microbio 31:19–31

Rao NN, Lutz S, Wurges K, Minor D (2009) Continuous biocatalytic processes. Org Process Res Dev 13:607–616

Rey FE, Heiniger EK, Harwood CS (2007) Redirection of metabolism for biological hydrogen production. Appl Environ Microbiol 73:1665–1671

Riggs SS, Heindel TJ (2006) Measuring carbon monoxide gas-liquid mass transfer in a stirred tank reactor for syngas fermentation. Biotechnol Prog 22:903–906

Rippka R, Deruelles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of Cyanobacteria. J Gen Microbiol 111:1–61

Rosche B, Li XZ, Hauer B, Schmid A, Buehler K (2009) Microbial biofilms: a concept for industrial catalysis? Trends in Biotechnol 27:636–643

Sipma J, Henstra AM, Parshina SN, Lens PNL, Lettinga G, Stams AJM (2006) Microbial CO conversions with applications in synthesis gas purification and bio-desulfurization. Crit Rev Biotechnol 26:41–65

Tirado-Acevedo O (2010) Production of bioethanol from synthesis gas using Clostridium ljungdahlii as a microbial catalyst. North Carolina State University, Raleigh

Acknowledgments

Support for these studies was provided to J.L.G., M.S.C., A.M.G., and M.C.F. by North Carolina Biotechnology Center (NCBC) grant number 2008-MRG-1104. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views and policies of the NCBC. J.S.J. was supported by a NCSU/NIH Molecular Biotechnology Training Program Traineeship. O.I.B. was supported by the Office of Fossil Energy—National Energy Technology Laboratory through subcontract AC 70110 O from Savannah River Nuclear Solutions, LLC. The authors would like to thank Orlin Velev and members of his laboratory group for assistance with the confocal laser scanning microscopy. All authors have agreed to submit this manuscript to Journal of Industrial Microbiology and Biotechnology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gosse, J.L., Chinn, M.S., Grunden, A.M. et al. A versatile method for preparation of hydrated microbial–latex biocatalytic coatings for gas absorption and gas evolution. J Ind Microbiol Biotechnol 39, 1269–1278 (2012). https://doi.org/10.1007/s10295-012-1135-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1135-8