Abstract

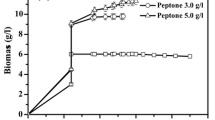

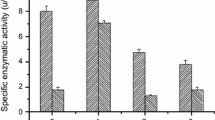

Semicontinuous fermentation using pellets of Rhizopus oryzae has been recognized as a promising technology for l-lactic acid production. In this work, semicontinuous fermentation of R. oryzae AS 3.819 for l-lactic acid production has been developed with high l-lactic acid yield and volumetric productivity. The effects of factors such as inoculations, CaCO3 addition time, and temperature on l-lactic acid yield and R. oryzae morphology were researched in detail. The results showed that optimal fermentation conditions for the first cycle were: inoculation with 4% spore suspension, CaCO3 added to the culture medium at the beginning of culture, and culture temperature of 32–34°C. In orthogonal experiments, high l-lactic acid yield was achieved when the feeding medium was (g/l): glucose, 100; (NH4)2SO4, 2; KH2PO4, 0.1; ZnSO4·7H2O, 0.33; MgSO4·7H2O, 0.15; CaCO3, 50. Twenty cycles of semicontinuous fermentation were carried out in flask culture. l-lactic acid yield was 78.75% for the first cycle and 80–90% for the repeated cycles; the activities of lactate dehydrogenases (LDH) were 7.2–9.2 U/mg; fermentation was completed in 24 h for each repeated cycle. In a 7-l magnetically stirred fermentor, semicontinuous fermentation lasted for 25 cycles using pellets of R. oryzae AS 3.819 under the optimal conditions determined from flask cultures. The final l-lactic acid concentration (LLAC) reached 103.7 g/l, and the volumetric productivity was 2.16 g/(l·h) for the first cycle; in the following 19 repeated cycles, the final LLAC reached 81–95 g/l, and the volumetric productivities were 3.40–3.85 g/(l·h).

Similar content being viewed by others

References

Jin QR, Wang BY (2000) Production and application handbook for organic acid from fermentation. Chin L Ind, Beijing

Rojan PJ, Nampoothiri KM, Pandey A (2007) Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Appl Microbiol Biotechnol 74:524–534

Zhang ZY, Jin B, Kelly JM (2007) Production of lactic acid from renewable materials by Rhizopus fungi. Biochem Eng J 35:251–263

Martak J, Schlosser S, Sabolova E, Kristofikova L, Rosenberg M (2003) Fermentation of lactic acid with Rhizopus arrhizus in a stirred tank reactor with a periodical bleed and feed operation. Process Biochem 38:1573–1583

Bai DM, Jia MZ, Zhao XM, Ban R, Shen F, Li XG, Xu SM (2003) L(+)-lactic acid production by pellet-form Rhizopus oryzae R1021 in a stirred tank fermentor. Chem Eng Sci 58:785–791

Liao W, Liu Y, Frear C, Chen SL (2007) A new approach of pellet formation of a filamentous fungus—Rhizopus oryzae. Bioresource Technol 98:3415–3423

Yu MC, Wang RC, Wang CY, Duan KJ, Sheu DC (2007) Enhanced production of L(+)-lactic acid by floc-form culture of Rhizopus oryzae. J Chin Inst Chem Eng 38:223–228

Yin PM, Yahiro K, Ishigaki T, Park Y, Okabe M (1998) L(+)-lactic acid production by repeated batch culture of Rhizopus oryzae in air-lift bioreactor. J Ferment Bioeng 85:96–100

Du JX, Cao NJ, Gong CS, Tsao GT (1998) Production of L-lactic acid by Rhizopus oryzae in a bubble column fermentor. Appl Biochem Biotechnol 70–72:323–329

Liu Y, Liao W, Chen S (2008) Co-production of lactic acid and chitin using a pelletized filamentous fungus Rhizopus oryzae cultured on cull potatoes and glucose. J Appl Microbiol 105:1521–1528

Zhu Y (2006) Production of L-lactic acid by self-immobilized Rhizopus oryzae. Dissertation Hefei University of Technology, Hefei

Buyukkileci a O, Hamamci H, Yucel M (2006) Lactate and ethanol productions by Rhizopus oryzae ATCC 9363 and activities of related pyruvate branch point enzymes. J Biosci Bioeng 102:464–466

Miura S, Arimura T, Hoshino M, Kojima M, Dwiarti L, Okabe M (2003) Optimization and scale-up of L-lactic acid fermentation by mutant strain Rhizopus sp MK-96–1196 in airlift bioreactors. J Biosci Bioeng 96:65–69

Liu Y, Liao W, Liu CB, Chen SL (2006) Optimization of l-(+)-lactic acid production using pelletized filamentous Rhizopus oryzae NRRL 395. Appl Biochem Biotechol 131:844–853

Papagianni M (2004) Fungal morphology and metabolite production in submerged mycelial processes. Biotechnol Adv 22:189–259

Oke IA (2009) Orthogonal experiments in the development of carbon-resin for chloride removal from solutions. Stat Methodol 6:109–119

Acknowledgments

Financial support from Hi-tech Research and Development Program of China (863 Program) and Program of the Key Laboratory for Agricultural Products Processing of Anhui Province (2009AKSY0102) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, X., Jiang, S., Liu, M. et al. Production of l-lactic acid by Rhizopus oryzae using semicontinuous fermentation in bioreactor. J Ind Microbiol Biotechnol 38, 565–571 (2011). https://doi.org/10.1007/s10295-010-0804-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0804-8