Abstract

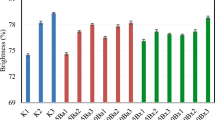

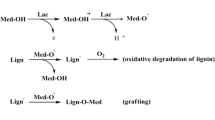

Recycled blue colored paper was treated with laccase under various combinations of physical and chemical parameters including enzyme concentration, temperature, oxygen, and reaction time. Laccase treatment of recycled dyed pulp increased acid group content, tear index, tensile index, and color removal in a dose-dependent manner. Lengthening the treatment time from 2 to 4 h was beneficial to acid group content (12% increase), dye removal, and tensile index but had a detrimental 8% decrease on the tear index. A higher reaction temperature (65 vs. 45 °C) had a beneficial effect on acid group content (+31%), and tensile index (+26%) and a slightly negative effect on tear index (−5%), but significantly reduced the ability of laccase to remove color. Comparison of reactions subjected to different levels of oxygen supplementation showed the greatest beneficial effect for laccase treatment with slow oxygen bubbling. The experimental results indicate that laccase treatment increases fiber carboxylic acid content and tensile strength, in addition to reducing the color of the enzyme treated paper.

Similar content being viewed by others

References

American Forest and Paper Association (AFPA)(2004) Recovered paper statistical high lights 2004 edn. http://www.stats.paperrecycles.org/

Gottsching L (1999) Ecological challenges of the 21st century. Revue ATIP 53:134–139

Darlington B, Jerzerc G, Magnotta V, Naddeo R, Waller F, White-Gaebe K (1992) Secondary fiber color stripping: evaluation of alternatives. TAPPI Pulping Conf Proc Bk 1:67–74

Camarero S, Ibarra D, Martinez AT, Romero J, Gutierrez A, del Rio JC (2007) Paper pulp delignification using laccase and natural mediators. Enzyme Microb Technol 40:1264–1271

Knutson K, Kirzan S, Ragauskas AJ (2005) Enzymatic biobleaching of two recalcitrant paper dyes with horseradish and soybean peroxidase. Biotechnol Lett 27:753–758

Abadulla E, Tzanov T, Costa S, Robra KH, Cavaco-Paulo A, Gubitz GM (2000) Decolorization and detoxification of textile dyes with a laccase from Trametes hirsute. Appl Environ Microbiol 66:3357–3362

d’Acunzo F, Galli C, Gentili P, Sergi F (2006) Mechanistic and steric issues in the oxidation of phenolic and non-phenolic compounds by laccase or laccase-mediator systems. The case of bifunctional substrates. New J Chem 30:583–591

Knutson K, Ragauskas AJ (2003) An auspicious application of laccase and hydrogen peroxidases for biobleaching of recalcitrant paper dyes. In 12th international symposium on wood and pulping chemistry, Madison, WI, USA, 2003. Tappi Press, Atlanta, 2003

Rochefort D, Leech D, Bourbonnais R (2004) Electron transfer mediator systems for bleaching of paper pulp. Green Chem 6:14–24

Chakar FS, Ragauskas AJ (2004) Biobleaching chemistry of laccase-mediator systems on high-lignin-content kraft pulps. Can J Chem 82(2):344–352

Viikari L, Kruus K, Buchert J (1999) Method for modification of cellulose WO/1999/23117 (PCT/FI1999/000861) Valtion Teknillinen Tutkimuskeskus, Finland

Zhang D, Chai XS, Pu Y, Ragauskas AJ (2007) Lignocellulosic fiber charge enhancement by catalytic oxidation during oxygen delignification. J Colloid Interface Sci 306:248–254

Mansfield SD (2002) Laccase impregnation during mechanical pulp processing—improved refining efficiency and sheet strength. Appita J 55:49–53

Lund M, Felby CF (2001) Wet strength Improvement of unbleached Kraft pulp though laccase catalyzed oxidation. Enzyme Microb Technol 28:760–765

Chandra RP, Ragauskas AJ (2002) Evaluating laccase facilitated coupling of phenolic acids to high kappa Kraft pulps. Enzyme Microb Technol 30:855–861

Chandra RP, Ragauskas AJ (2001) Sculpting the molecular weight of lignin via laccase. In 11th international symposium on wood and pulping chemistry. Nice, France, 2001, Tappi Press, Atlanta 2:39–43

Bourbonnais R, Paice MG, Freiermuth B, Bodie E, Borneman S (1997) Reactivities of various mediators and laccases with kraft pulp and lignin model compounds. Appl Environ Microbiol 63:4627–4632

Sealey J, Ragauskas AJ (1998) Residual lignin studies of laccase-delignified kraft pulps. Enzyme Microb Technol 23:422–426

Knutson K, Ragauskas A (2004) Laccase-mediator biobleaching applied to a direct yellow dyed paper. Biotechnol Prog 20:1893–1896

TAPPI test methods (2002) Tappi Press, Atlanta

Sharpe PE (1996) Optical testing in 1996 deinking short course. TAPPI Press, Atlanta 547–579

Peterson ME, Daniel RM, Danson MJ, Eisenthal R (2007) The dependence of enzyme activity on temperature: determination and validation of parameters. Biochem J 402:331–337

Balakshin M, Chen CL, Gratzl JS, Kirkman AG, Jakob H (2001) Biobleaching of pulp with dioxygen in laccase-mediator system—effect of variables on the reaction kinetics. J Mol Catal B Enzym 16:205–215

Gerken BM, Wattenbach C, Linke D, Zorn H, Berger RG, Parlar H (2005) Tweezing-adsorptive bubble separation analytical method for the selective and high enrichment of metalloenzymes. Anal Chem 77:6113–6117

Bourbonnais R, Paice MG (1990) Oxidation of non phenolic substrates an expanded role for laccase in lignin biodegradation. FEBS Lett 267:99–102

Crestini C, Argyropoulous DS (1998) The early oxidative biodegradation steps of residual kraft lignin models with laccase. Bioorg Med Chem 6:2161–2169

Zille A, Ramalho P, Tzanov T, Millward R, Aires V, Cardoso MH, Ramalho MT, Guebitz GM, Cavaco-Paulo A (2004) Predicting dye biodegradation from redox potentials. Biotechnol Prog 20:1588–1592

D’Acunzo F, Baiocco P, Fabbrini M, Galli C, Gentili PA (2002) Mechanistic survey of the oxidation of alcohols and ethers with the enzyme laccase and its mediation by TEMPO. Eur J Org Chem 24:4195–4201

Saito T, Isogai A (2005) A novel method to improve wet strength of paper. Tappi J 4:3–8

d’Acunzo F, Galli C, Masci B (2002) Oxidation of phenols by laccase and laccase-mediator systems. Solubility and steric issues. Eur J Biochem 269:5330–5335

Barrreca AM, Sjoegren B, Fabbrini M, Galli C, Gentili P (2004) Catalytic efficiency of some mediators in laccase-catalyzed alcohol oxidation. Biocatal Biotransformation 22:105–112

Granfeldt T (1998) Environmental friendly bleaching of white grade deinked pulps to high brightness levels. Kami Pa Gikyoshi 52(7):929–936

Acknowledgments

We are grateful to Department of Biotechnology, Ministry of Science and Technology, Government of India for funding an overseas Associateship to Dr. C. Mohandass. The authors also wish to thank NSF (EEC-0332554) for their support, in part, of these studies. The technical assistance of Mr. Zheng Deng was highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohandass, C., Knutson, K. & Ragauskas, A.J. Laccase treatment of recycled blue dyed paper: physical properties and fiber charge. J Ind Microbiol Biotechnol 35, 1103–1108 (2008). https://doi.org/10.1007/s10295-008-0388-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0388-8